Products

Tornado Full-Electric EBM Machine

- The small Tornado series blow molding machine is specially customized for the efficient production of small blow molding products.

- The whole machine is compact, fast, the most stable operation, accurate temperature control, the lowest energy consumption, the most automated series.

- The machine adapts to small batch orders, reducing investment in molds and auxiliary machines and facilitating production switching.

- With innovative swing type swing frame design, it achieves efficient mold shifting and saves head-up movements.

Description:

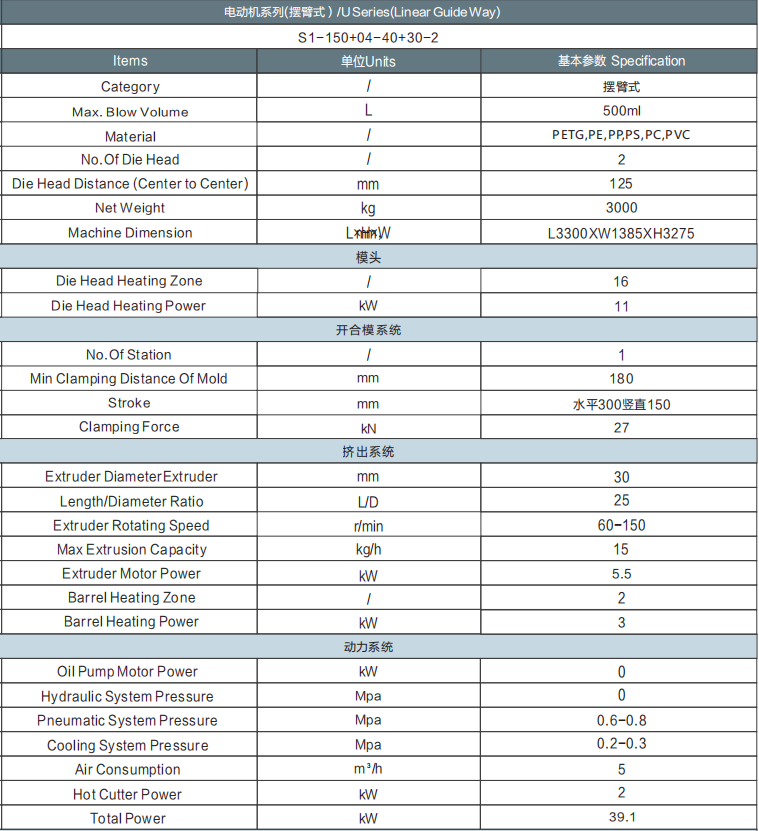

Single Station

Single Head

Production Volume: Below 1L

Multi layers: 1 Layer

Multi cavities: 1-2 cavity

Specialize for the PE/PP/PETG/ PVC/Nylon/Co-Extrusion

Features

Siemens TP700 color touch screen of 7 inches, 800 x 480 resolution, 16 megapixels.

Platform lifting function, adapted to different mold height and different blow molding process requirements.

Full-electric system, adopting servo-motor technology, has the character of power saving, fast action, convenient parameter adjustment.

Automatic lubrication system, reducing the workload of equipment maintenance.

Die head pressing piston and storage cavity are made of hard and wear-resistant materials, which are durable.

A pull-down width device, which can stretch the material tube to both sides and then blow air, so that the bottle shape is more uniform and fuller.

For large caliber material pipe, equipped with a pre-clamping bottle embryo device to glue the material pipe mouth, so as to insert the pen and blow air.