Products

55K1 X2.2D

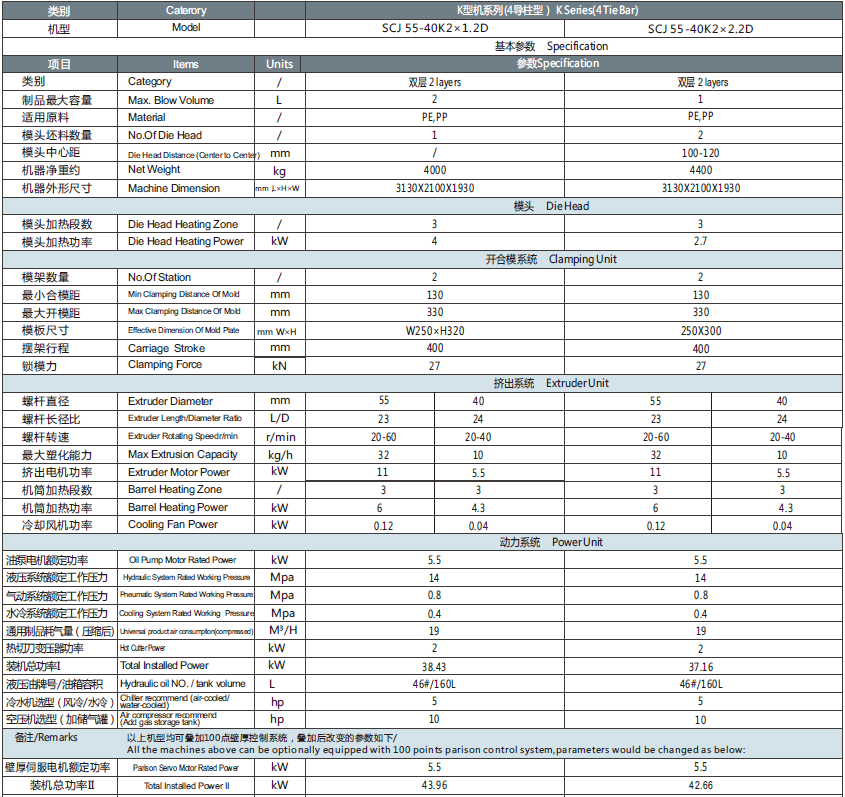

Features: Four-column balanced put rod structure for over-long or over-wide molds. Products can come out from two sides and bottom of the machine, adapted different products Touchscreen with human-computer interface with simply and convenient operation. Double pump for oil supply, which can save energy Double proportional valves controlling the speed and pressure of oil, making movement of oil swift and stable.

Description:

As the very first series of Leshan, the column-guide rail machine is an economic equipment taking up small space. Because of its relatively low cost, it has become the best choice for customers who has a tight budget or little knowledge about EBM machine. Though being an old model, the machine is still popular for its low cost and proper productivity. It’s its 4-column structure and 3-plate clamping system that allows the machine to clamp long or wide molds with suitable clamping forces. Thus, the machine can produce several kinds of plastic bottles, such as milk bottles, cosmetic bottles and sea balls.

Single/Double Station

Single/Double/Triple/Quadruple...8 Head

Production Volume:2ml~20L

Multi layers: Co-Extrusion 1-4 Layers

Multi cavities: 1~8 cavities

Specialize for the PE/PP/PETG/PVC/Nylon/Co-Extrusion Material

Features

Platform left and right movement function.

Blow pin use air compressor (standard configuration for 15L machine).

Mold integrated deflasher.

Extrusion platform left and right movement function.

Porcelain connector heating ring and heating plate.