Matters Needing Attention When the Bottle Blowing Machine Stops

NO.1 XINHUI ROAD, WUSHA NEIGHBORHOOD COMMITTEE, DALIANG, SHUNDE DISTRICT, FOSHAN CITY, GUANGDONG PROVINCE, CHINA

Matters Needing Attention When the Bottle Blowing Machine Stops

Matters needing attention when the bottle blowing machine stops

1. First, close the cooling water tower, water pump, water cooler and mold cooling system, etc., and cut off the water source of the bottle blowing machine and auxiliary machine

2. Turn off the incoming power supply and compressed air source of the machine

3. At the tailor both sides of the bottle blowing machine, remove the main cooling water outlet pipe and empty the water in the pipe

4. The main cooling components of the bottle blowing machine are: oil cooler, mold cooling system, air filter, air heat exchanger, mold, etc

5. After closing the water source, remove the inlet and outlet water joint, empty the water inside the cooling element, and blow out all the residual moisture inside the cooling element with high-pressure air to avoid rust or oxidation

6. When the bottle blowing machine is used again, reinstall the inlet and outlet water joints of each cooling element, and pay attention to cleaning the filter screen on the inlet pipe of the oil cooler

A detailed explanation of shutdown of bottle blowing machine

Firstly, Matters needing attention for barrel and hopper before shutdown

Before stopping, take out the excess plastic inside the hopper and exhaust the material inside the machine barrel until it can not be discharged.

Secondly, Machine inlet power supply and compressed air source

1. Turn off the incoming power of the machine

2. Turn off the intake air source of the machine

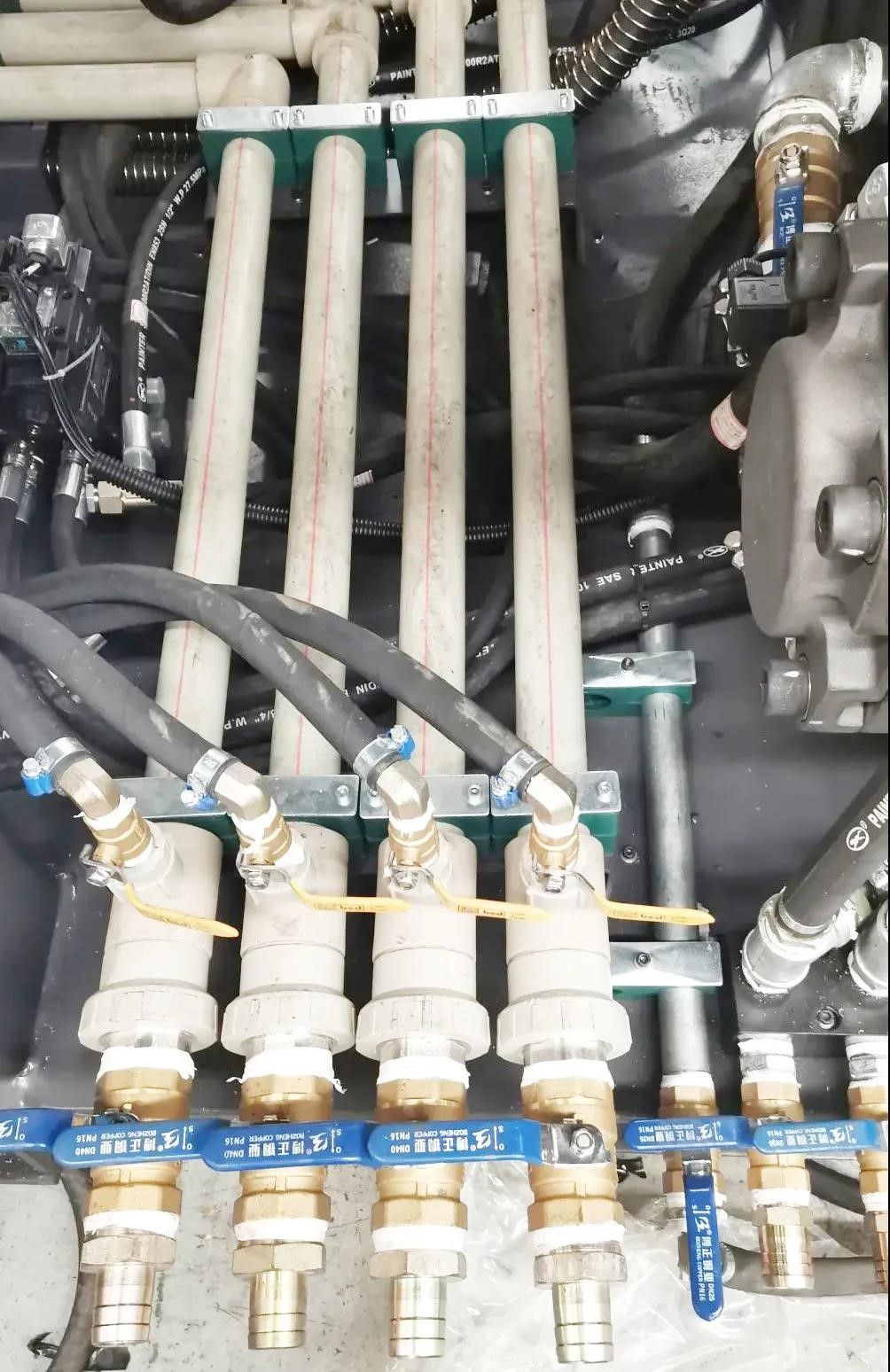

3. external type oil cooler

Close the inlet water, open the nozzle, connect the water with the container, and empty the water in the external oil cooler; Remove the intake pipe (the return pipe is not dismantled for the time being), and blow with high-pressure air from the intake port until there is no water flowing out of the discharge port.

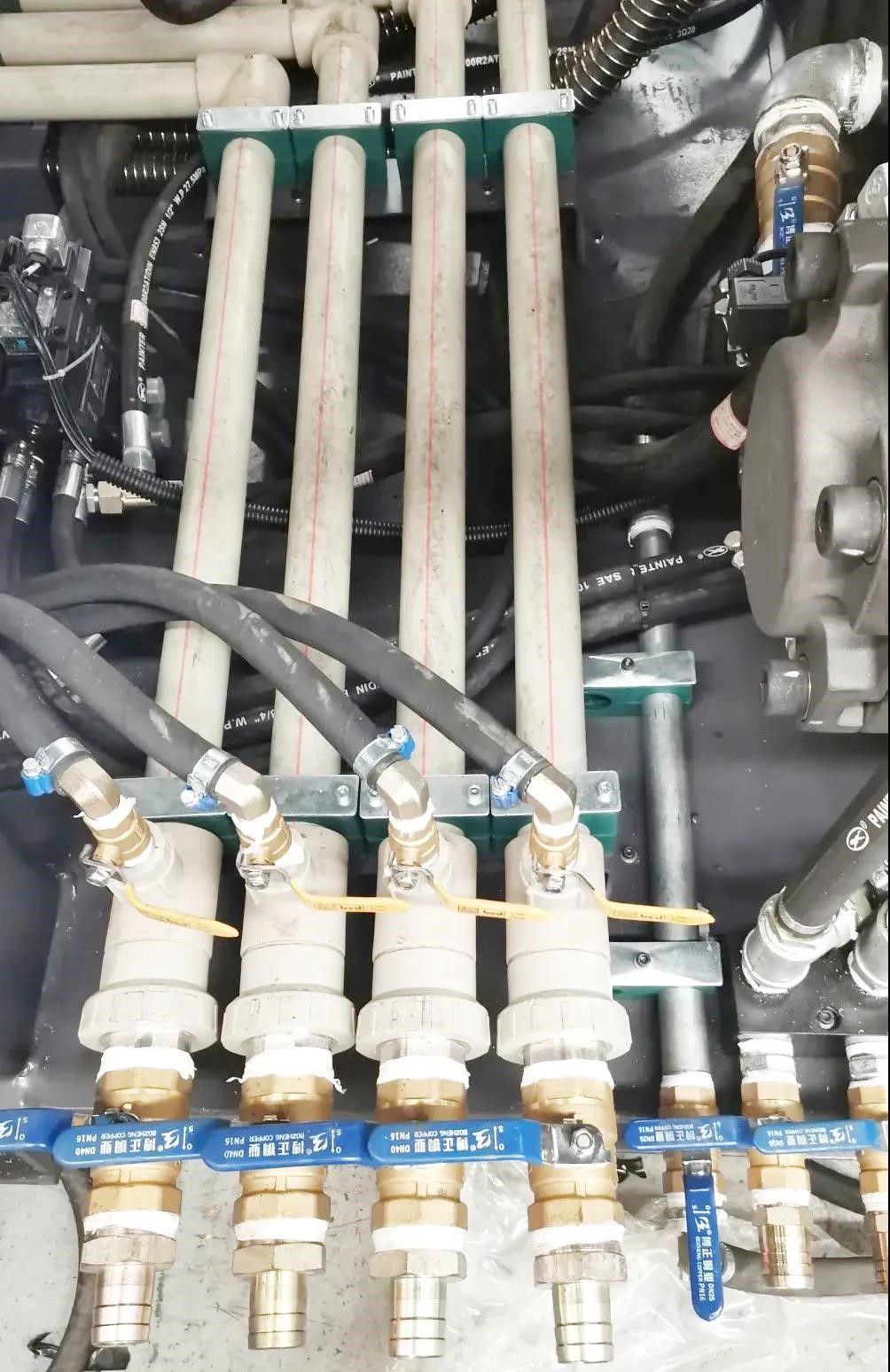

4. Mold water block

Use compressed air to drain the water inside the water block to prevent freezing and cracking.

5.Compressed air heat exchanger

Use compressed air to drain the water inside the water block to prevent freezing and cracking.

6. Air purifier

Drain the water from the lower outfall.

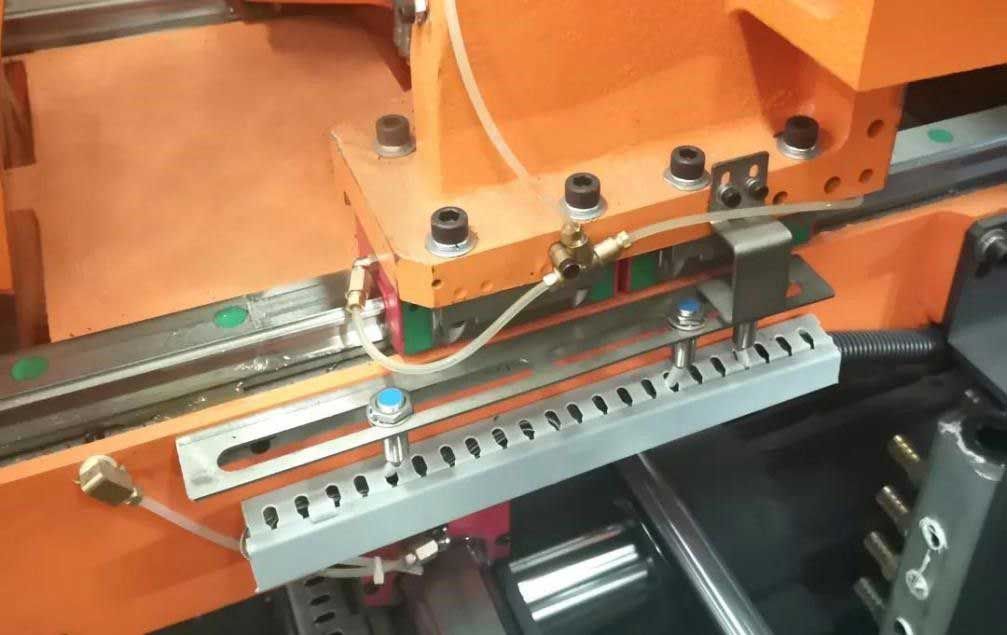

7.Total inlet and outlet water pipes of the bottle blowing machine

Close the water intake, remove the return pipe, and empty the water in the pipe to prevent freezing and cracking.

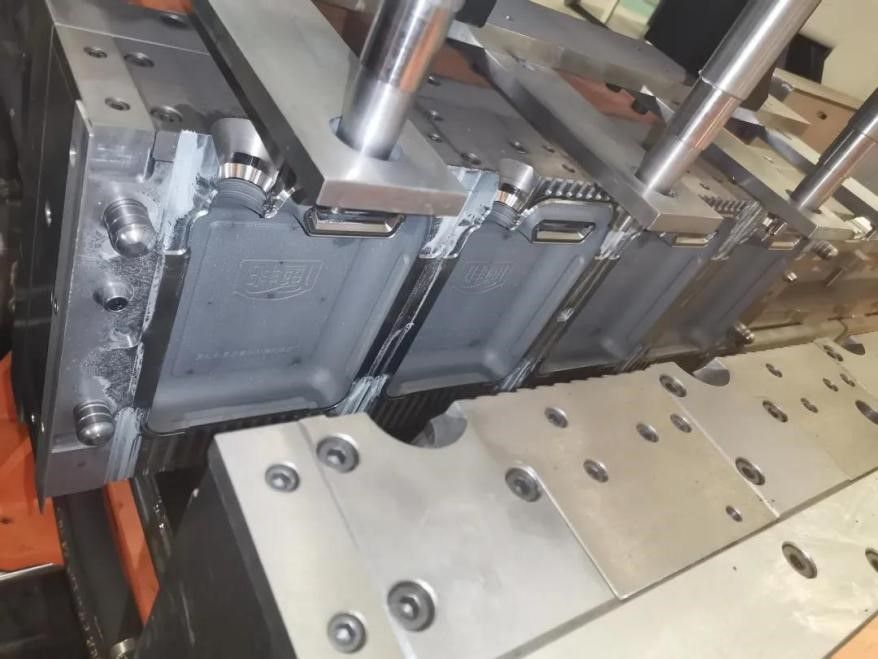

8. Blow mold

Disconnect the inlet pipe, use compressed air, and remove the residual water stains in the mold. Prevent frostbite mold, spray rust inhibitor inside mold cavity to prevent mold cavity from rusting.

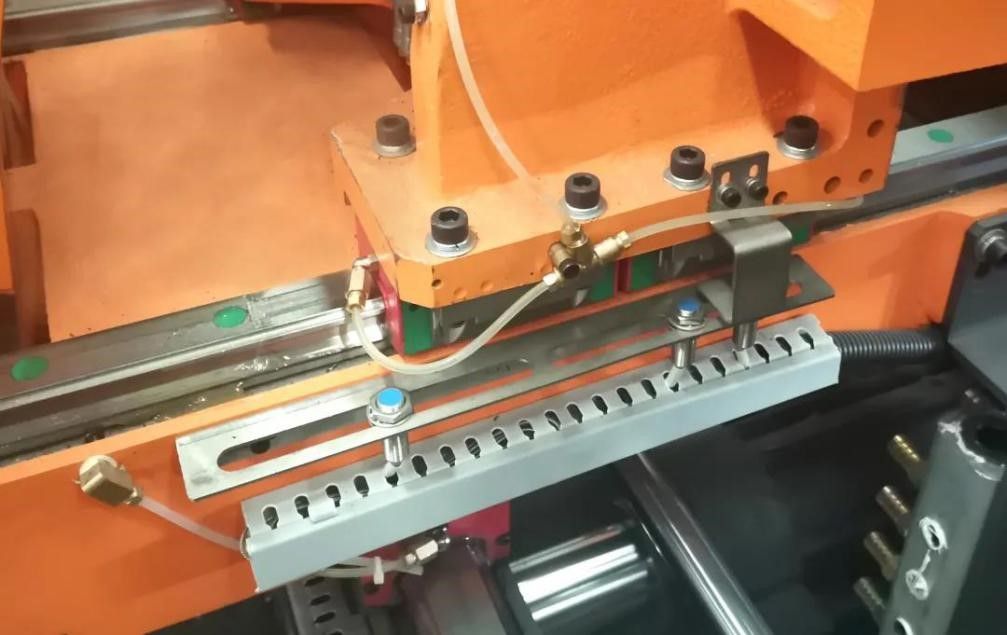

9. guide rail and guide pillar

Clean up the grease on the guide rail and guidepost, and add new lubricating oil.

Only by systematic maintenance can the equipment cope with heavy work in the best condition. If you have any questions or comments during the actual operation, you are welcome to contact us. We will serve and help you wholeheartedly. Your valuable comments will be improved in the upgrading of Leshan's products and services in the future.