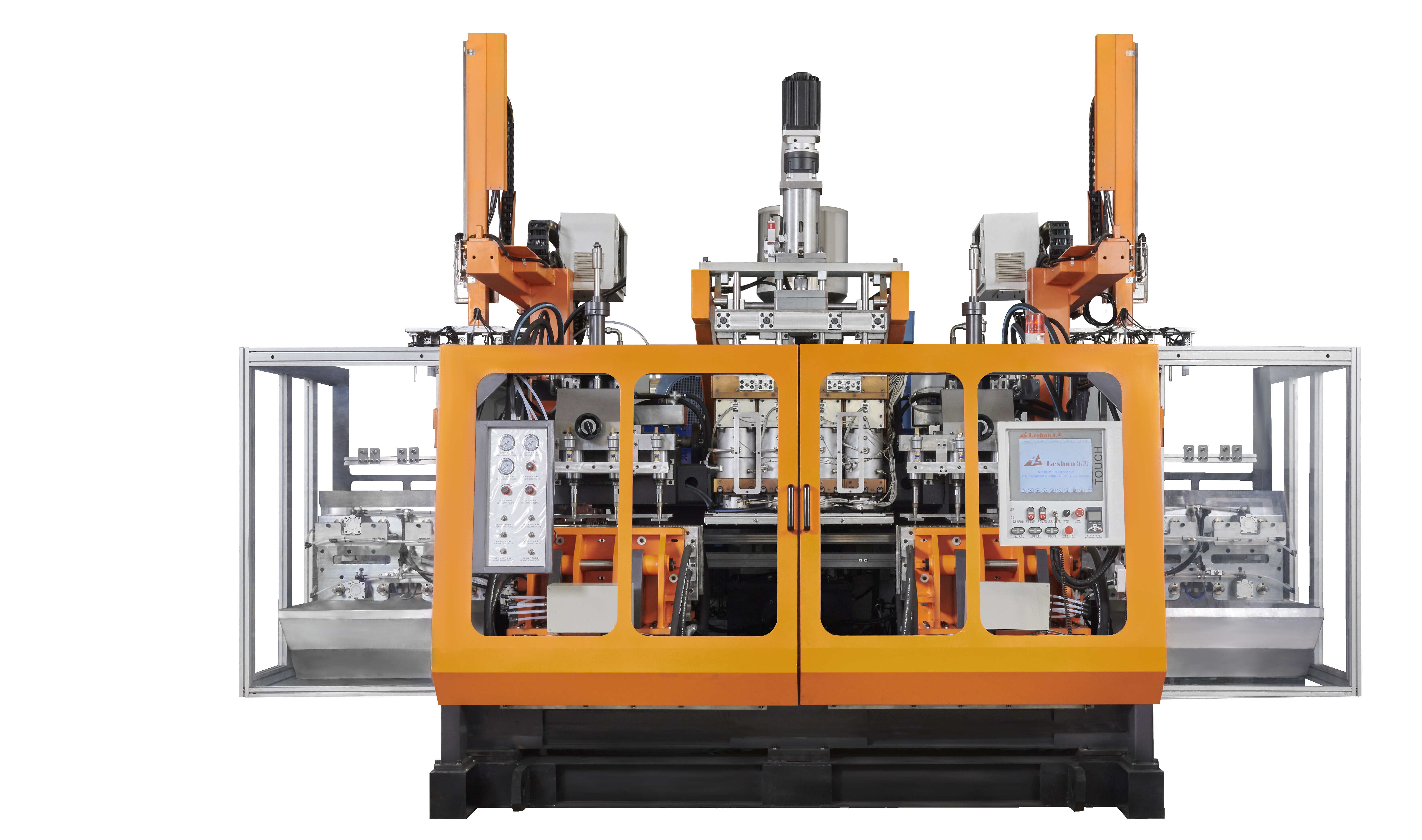

Extrusion blow molding machinery

Extrusion blow molding machinery

Leshan Machinery Company was established in 1995 and is located in Foshan, Guangdong. Our business scope includes exporting Hydraulic Blow Molding Machine, All-Electric PET Blow Molding Machine,High-precision Mould,athlon series hydraulic machine,Engine oil bottle blow molding machine,Chemical barrel blow molding machine,multi-layer coextrusion blow molding machine,Milk bottle blow molding machine,Extrusion Die Head,PET Machine,Cleaning bottle blow molding machine,Food bottle blow molding machine,Irregular shape product blow molding machine,Daily chemistry bottle blow molding machine and other equipment. We are also armed with comprehensive strength such as strong R&D power,production marketing,technical support,etc... Through years of creation , Leshan has been transformed the patent technology into application.

We also use International standards and the ISO9001:2012 quality management system in producing. Currently, our company's products are exported to over 50 countries and regions worldwide. Including: Russia, Australia, Poland, Saudi Arabia, Bengal, Vietnam , etc...

| Parameter | Information |

| Product Name | extrusion blow molding machinery |

| Place of Origin | Foshan,Guangdong,China |

| Brand Name | Leshan |

| Condition | New |

| Video outgoing-inspection | Provided |

| Machinery Test Report | Provided |

| Warranty of core components | 1 year |

| Warranty | 1year |

| Port | ShunDe/GuangZhou/ShenZhen China |

| Application | Bottle |

| Core Components | Pump,Gearbox,Pressure vessel,Gear,Engine,Bearing...etc |

| Color | customized |

| Plastic Processed | PA,PP,HDPE,PVC,PE,ABS...etc |

| Certification | CE,ISO9001:2012... |

| PLC Brand | Siemens |

| Packaging Details | Standard exporting machine packing with plastic film |

| Service | Field installation, commissioning and training |

| Automation | Automation |

| Supply Ability | 500 Set/Sets per year |

| Lead time (days) | 70 (To be negotiated) |

Please note: The above table data is for reference only. For specific information, please contact us.

extrusion blow molding machinery also offer flexibility and scalability. It can adjust the production process and parameters according to production needs to meet different product requirements. At the same time, the blow molding machine also has extension functions. By adding additional devices, it can realize bottle mouth separation, label attachment and other processing to meet the application needs of more fields.

extrusion blow molding machinery---FAQs Guide

2.How to ensure the quality of products produced by extrusion blow molding machinery?

3.What are the dimensions and weight of the extrusion blow molding machinery?

4.How to control the energy consumption of extrusion blow molding machinery?

5.How does the extrusion blow molding process differ from injection blow molding, and what types of products are typically produced using each method?

6.What are the key components of a extrusion blow molding machinery?

7.Where is your factory located? How can I visit there?

8.What energy-saving measures are there for extrusion blow molding machinery?

9.What are the common problems in the production process of extrusion blow molding machinery?

10.How to improve the production capacity and speed of extrusion blow molding machinery?

11.How to optimize the efficiency of plastic blow molding machine?

1.What are the steps for cleaning and maintaining a extrusion blow molding machinery?

We adhere to the principle of integrity and transparency, and establish long -term relationships with partners, and we attach great importance to this detail.

1. Shut off and unplug the machine: Before starting any cleaning or maintenance, make sure the machine is turned off and unplugged to avoid any accidents.

2. Remove excess material: Use a scraper or a brush to remove any excess material from the machine, including the mold, extruder, and die head.

3. Disassemble the machine: Depending on the type of blow molding machine, you may need to disassemble certain parts to access all the areas that need cleaning. Refer to the manufacturer's manual for specific instructions.

4. Clean the mold: Use a mild detergent and warm water to clean the mold. Make sure to remove any residue or buildup from the mold surface. You can also use a specialized mold cleaner for tougher stains.

5. Clean the extruder and die head: Use a brush or scraper to remove any residue or buildup from the extruder and die head. You can also use a specialized cleaner for these parts.

6. Check and clean the cooling system: The cooling system is essential for maintaining the temperature of the machine. Check for any clogs or buildup in the cooling channels and clean them with a brush or compressed air.

7. Lubricate moving parts: Use a lubricant recommended by the manufacturer to lubricate all the moving parts of the machine. This will help prevent wear and tear and ensure smooth operation.

8. Inspect and replace worn parts: Check all the parts of the machine for any signs of wear and tear. Replace any damaged or worn parts to ensure the machine's optimal performance.

9. Reassemble the machine: Once all the parts are cleaned and inspected, reassemble the machine following the manufacturer's instructions.

10. Test the machine: Before using the machine again, run a test cycle to ensure everything is working correctly.

11. Regular maintenance: To keep the machine in good working condition, it is essential to perform regular maintenance tasks such as cleaning, lubricating, and inspecting the machine. Refer to the manufacturer's manual for a recommended maintenance schedule.

2.How to ensure the quality of products produced by extrusion blow molding machinery?

We have established long-term and stable partnerships with our suppliers, so we have great advantages in price and cost and quality assurance.

1. Regular Maintenance: Regular maintenance of the blow molding machine is essential to ensure its proper functioning and production of high-quality products. This includes cleaning, lubrication, and replacement of worn-out parts.

2. Quality Control Checks: Implementing a quality control system that includes regular checks and inspections of the products produced by the blow molding machine can help identify any defects or issues early on.

3. Proper Training: Ensure that the operators and technicians operating the blow molding machine are properly trained and have a good understanding of the machine's capabilities and settings.

4. Use High-Quality Materials: The quality of the raw materials used in the blow molding process directly affects the quality of the final product. Therefore, it is important to use high-quality materials that are suitable for the specific product being produced.

5. Optimize Process Parameters: The process parameters such as temperature, pressure, and speed can significantly impact the quality of the products produced. It is important to optimize these parameters for each product to ensure consistent quality.

6. Regular Testing: Conducting regular testing of the products produced by the blow molding machine can help identify any issues or defects and make necessary adjustments to improve the quality.

7. Implement Quality Standards: Adhering to industry standards and regulations for blow molding can help ensure the production of high-quality products.

8. Continuous Improvement: Continuously monitoring and analyzing the production process can help identify areas for improvement and implement changes to enhance the quality of the products produced.

3.What are the dimensions and weight of the extrusion blow molding machinery?

We are committed to providing personalized solutions and established long -term strategic cooperative relationships with customers.

The dimensions and weight of a blow molding machine can vary depending on the specific model and manufacturer. However, a general estimate for a standard blow molding machine is approximately 10 feet in length, 6 feet in width, and 8 feet in height. The weight can range from 5,000 to 10,000 pounds.

4.How to control the energy consumption of extrusion blow molding machinery?

We are a professional extrusion blow molding machinery company dedicated to providing high quality products and services.

1. Use energy-efficient machines: When purchasing blow molding machines, opt for models that are energy-efficient and have a high energy star rating. These machines are designed to consume less energy while still maintaining high production efficiency.

2. Regular maintenance: Regular maintenance of the machines is crucial in controlling energy consumption. This includes cleaning and lubricating the machines, checking for leaks, and replacing worn-out parts. A well-maintained machine will operate more efficiently and consume less energy.

3. Optimize production processes: Analyze the production processes and identify areas where energy consumption can be reduced. For example, reducing the amount of air pressure used in the blowing process can significantly reduce energy consumption.

4. Use energy-saving features: Many blow molding machines come with energy-saving features such as automatic shut-off, idle mode, and variable speed drives. These features can help reduce energy consumption when the machine is not in use or operating at a lower speed.

5. Monitor energy usage: Install energy meters to monitor the energy consumption of the machines. This will help identify areas where energy is being wasted and allow for adjustments to be made to reduce consumption.

6. Use energy-efficient materials: The type of material used in the blow molding process can also affect energy consumption. Opt for materials that require less energy to heat and mold, such as lightweight plastics.

7. Implement energy management systems: Consider implementing an energy management system that can track and analyze energy usage in real-time. This will help identify patterns and areas for improvement.

8. Train employees: Proper training of employees on the operation and maintenance of the machines can help reduce energy consumption. They should be aware of energy-saving practices and encouraged to follow them.

9. Turn off machines when not in use: Make it a practice to turn off the machines when they are not in use, such as during breaks or at the end of the day. This will help save energy and reduce unnecessary wear and tear on the machines.

10. Regularly review and update energy-saving strategies: Regularly review and update your energy-saving strategies to ensure they are still effective. As technology advances, new energy-saving techniques may become available, so it is essential to stay informed and make necessary changes.

5.How does the extrusion blow molding process differ from injection blow molding, and what types of products are typically produced using each method?

We have been working hard to improve service quality and meet customer needs.

Extrusion blow molding and injection blow molding are two different processes used to manufacture plastic products. While both methods involve melting plastic and shaping it into a desired form, there are some key differences between the two.

Extrusion blow molding is a process in which a molten tube of plastic, called a parison, is extruded through a die and then inflated to form a hollow product. The parison is then cooled and the mold opens to release the finished product. This process is commonly used to produce bottles, containers, and other hollow objects.

On the other hand, injection blow molding involves injecting molten plastic into a mold cavity, where it is then cooled and solidified. The mold then opens to release the finished product. This process is commonly used to produce small, complex, and precise products such as medical devices, pharmaceutical packaging, and small bottles.

One of the main differences between the two processes is the way the plastic is shaped. In extrusion blow molding, the plastic is shaped by the inflation of the parison, while in injection blow molding, the plastic is shaped by the mold cavity.

Another difference is the type of molds used. In extrusion blow molding, the molds are typically made of two halves that come together to form the desired shape. In injection blow molding, the molds are usually made of a single piece that is opened and closed to release the product.

The type of plastic used also differs between the two processes. Extrusion blow molding is typically used for high-density polyethylene (HDPE) and polyethylene terephthalate (PET) plastics, while injection blow molding is commonly used for polypropylene (PP) and polyethylene (PE) plastics.

In terms of product applications, extrusion blow molding is commonly used for larger, more simple products such as bottles and containers, while injection blow molding is used for smaller, more complex products such as medical devices and pharmaceutical packaging.

In summary, extrusion blow molding and injection blow molding are two different processes used to manufacture plastic products. While both methods involve melting plastic and shaping it into a desired form, they differ in the way the plastic is shaped, the type of molds used, and the types of products produced.

6.What are the key components of a extrusion blow molding machinery?

Our extrusion blow molding machinery products have competitive and differentiated advantages, and actively promote digital transformation and innovation.

1. Extruder: This is the main component of a blow molding machine, which melts and forms the plastic material into a parison (hollow tube).

2. Die Head: The die head is responsible for shaping the parison into the desired shape and size.

3. Clamping Unit: This unit holds the mold in place and provides the necessary pressure for the blowing process.

4. Blow Pin: The blow pin is used to inflate the parison and shape it against the mold.

5. Cooling System: After the parison is blown and formed into the desired shape, a cooling system is used to cool and solidify the plastic.

6. Ejection System: Once the plastic has cooled and solidified, the ejection system removes the finished product from the mold.

7. Control System: The control system is responsible for monitoring and controlling the various components of the machine, such as temperature, pressure, and speed.

8. Mold: The mold is a crucial component of a blow molding machine, as it determines the final shape and size of the product.

9. Hydraulic System: The hydraulic system provides the necessary power and pressure for the various movements and functions of the machine.

10. Electrical System: The electrical system supplies power to the machine and controls the various electrical components.

11. Safety Features: Blow molding machines are equipped with various safety features, such as emergency stop buttons, safety guards, and sensors, to ensure safe operation.

7.Where is your factory located? How can I visit there?

Our factory is located in Shunde, Foshan City, Guangdong Province, China. All our clients, from home or abroad, are warmly welcome to visit us!

8.What energy-saving measures are there for extrusion blow molding machinery?

I have a comprehensive after -sales service system, which can pay attention to market trends in time and adjust our strategy in a timely manner.

1. Use energy-efficient motors: Switching to energy-efficient motors can significantly reduce the energy consumption of a blow molding machine. These motors use less electricity and produce less heat, resulting in lower energy costs.

2. Optimize air pressure: Adjusting the air pressure to the minimum required level can reduce the energy consumption of the compressor and save energy.

3. Use variable frequency drives (VFDs): VFDs can adjust the speed of the motor to match the required output, reducing energy consumption and wear on the motor.

4. Insulate heating elements: Insulating the heating elements of the machine can reduce heat loss and improve energy efficiency.

5. Use LED lighting: Replacing traditional lighting with energy-efficient LED lights can reduce energy consumption and save on electricity costs.

6. Regular maintenance: Proper maintenance of the machine, including cleaning and lubrication, can improve its efficiency and reduce energy consumption.

7. Implement a shutdown schedule: Setting a shutdown schedule for the machine when it is not in use can save energy and reduce wear and tear on the machine.

8. Use energy-efficient materials: Using energy-efficient materials, such as lightweight plastics, can reduce the energy required to produce and transport the products.

9. Implement a heat recovery system: A heat recovery system can capture and reuse the heat generated during the blow molding process, reducing the energy needed to heat the material.

10. Invest in a high-efficiency machine: Upgrading to a newer, more energy-efficient blow molding machine can result in significant energy savings in the long run.

9.What are the common problems in the production process of extrusion blow molding machinery?

As one of the extrusion blow molding machinery market leaders, we are known for innovation and reliability.

1. Inconsistent Wall Thickness: This is a common problem in blow molding machines where the thickness of the plastic material is not uniform throughout the product. This can lead to weak spots in the product and affect its overall strength and durability.

2. Flashing: Flashing occurs when excess plastic material leaks out of the mold during the production process. This can result in a rough or uneven surface on the final product, affecting its appearance and functionality.

3. Warping: Warping is a common problem in blow molding machines where the product becomes distorted or deformed during the cooling process. This can be caused by uneven cooling or improper mold design.

4. Air Traps: Air traps occur when air gets trapped inside the mold during the production process. This can result in air bubbles or voids in the final product, affecting its strength and appearance.

5. Poor Surface Finish: Poor surface finish can be caused by a variety of factors, including improper mold design, poor quality plastic material, or inadequate cooling. This can result in a rough or uneven surface on the final product.

6. Leaks: Leaks can occur in blow molding machines due to worn or damaged seals, improper alignment of the mold, or inadequate clamping force. This can result in product defects and production downtime.

7. Contamination: Contamination can occur in the production process when foreign particles or impurities get mixed in with the plastic material. This can result in defects in the final product and affect its quality and functionality.

8. Machine Malfunctions: Like any other machinery, blow molding machines can experience malfunctions such as electrical issues, mechanical failures, or software glitches. These can result in production delays and affect the overall efficiency of the production process.

10.How to improve the production capacity and speed of extrusion blow molding machinery?

We pay attention to user experience and product quality, and provide the best product quality and lowest production cost for cooperative customers.

1. Regular Maintenance: Regular maintenance of the blow molding machine is essential to ensure its smooth functioning and prevent breakdowns. This includes cleaning, lubricating, and replacing worn-out parts.

2. Use High-Quality Materials: The quality of the materials used in the blow molding process can greatly affect the production capacity and speed. Using high-quality materials can result in faster production and better quality products.

3. Optimize the Design: The design of the blow molding machine can also impact its production capacity and speed. Optimizing the design to reduce the number of steps and improve the efficiency of the process can increase the production speed.

4. Increase Automation: Automation can greatly improve the production capacity and speed of blow molding machines. Automated processes can reduce the need for manual labor and increase the accuracy and speed of production.

5. Use Advanced Technology: Upgrading to newer and more advanced blow molding technology can significantly improve the production capacity and speed. This includes using computer-controlled systems, advanced sensors, and other technologies that can optimize the production process.

6. Train Operators: Properly trained operators can greatly improve the efficiency and speed of the blow molding process. They should be trained in operating the machine, troubleshooting common issues, and performing routine maintenance.

7. Implement Lean Manufacturing Principles: Implementing lean manufacturing principles can help identify and eliminate waste in the production process, resulting in increased efficiency and speed.

8. Increase the Number of Cavities: Increasing the number of cavities in the blow molding machine can significantly increase the production capacity. This allows for more products to be produced in a single cycle, reducing the overall production time.

9. Optimize Cooling Time: The cooling time of the products can greatly impact the production speed. Optimizing the cooling time by using advanced cooling methods can reduce the overall production time.

10. Monitor and Analyze Production Data: Regularly monitoring and analyzing production data can help identify bottlenecks and areas for improvement. This can help optimize the production process and increase the production capacity and speed.

11.How to optimize the efficiency of plastic blow molding machine?

It can improve the blowing process, improve the cooling water transportation of the mold, improve the machine action time, improve the shape of the cup to make the material tube become even, thus reducing the molding cycle time of the product.

Tags: extrusion blow mold machine , extrusion blow molding machine 2l , extrusion blowing mold