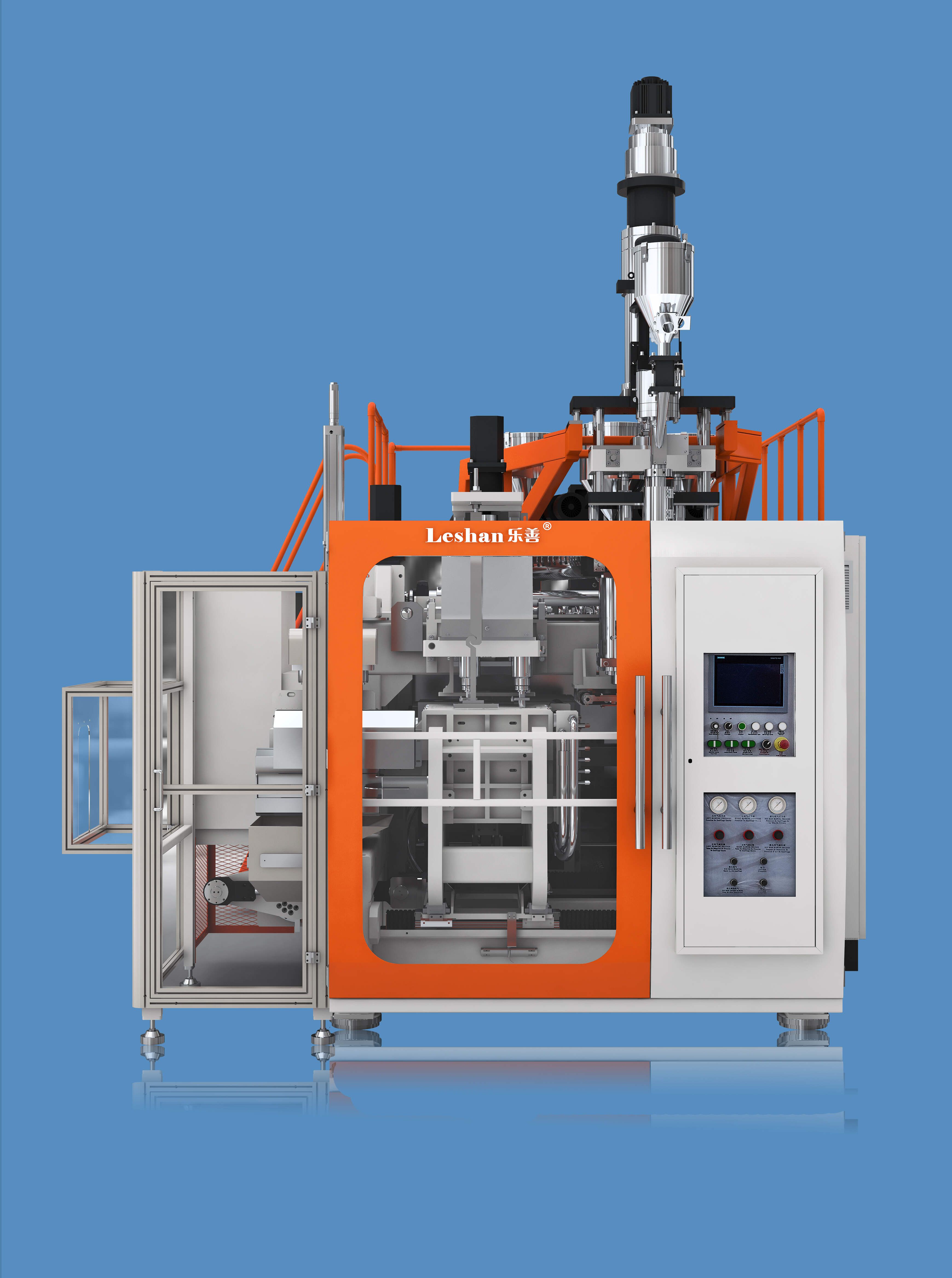

Extrusion Blow Molding Machine Exporter

Extrusion Blow Molding Machine Exporter

Leshan Machinery Company is a professional manufacturer of blow molding machines that integrates research and development, design, manufacturing, technical services, and marketing. The company is located in Foshan, Guangdong, adjacent to large and medium-sized cities such as Shenzhen, Guangzhou, and Dongguan. Our products include Cleaning bottle blow molding machine,Irregular shape product blow molding machine,Blowing Mould & Injection Mould,Milk bottle blow molding machine,Chemical barrel blow molding machine,Auxiliary machine,Engine oil bottle blow molding machine,athlon series hydraulic machine,Daily chemistry bottle blow molding machine,Extrusion Die Head, etc.

The company's factory covers an area of over 10000 square meters and has over 300 technical and staff members. We are still adopting international standards and ISO9001:2012 quality management system in production. Therefore, the production quality, efficiency, energy consumption, and control maintenance of Leshan blow molding machines are among the top in the domestic industry, and their sales are far ahead of the domestic industry.

| Parameter | Information |

| Product Name | extrusion blow molding machine exporter |

| Place of Origin | Foshan,China |

| Brand Name | Leshan |

| Condition | New |

| Video outgoing-inspection | Provided |

| Machinery Test Report | Provided |

| Warranty of core components | 1 year |

| Warranty | 1year |

| Port | ShunDe/GuangZhou/ShenZhen China |

| Application | Bottle |

| Core Components | Gearbox,Motor,Pump,Engine,Pressure vessel,Gear...etc |

| Color | customized |

| Plastic Processed | PC,ABS,HDPE,EVA,Polystyrene,PE...etc |

| Certification | CE,ISO9001:2012... |

| PLC Brand | Siemens |

| Packaging Details | Standard exporting machine packing with plastic film |

| Service | Free spare parts |

| Automation | Automation |

| Supply Ability | 500 Set/Sets per year |

| Lead time (days) | 70 (To be negotiated) |

Please note: The above table data is for reference only. For specific information, please contact us.

extrusion blow molding machine exporter also offer flexibility and scalability. It can adjust the production process and parameters according to production needs to meet different product requirements. At the same time, the blow molding machine also has extension functions. By adding additional devices, it can realize bottle mouth separation, label attachment and other processing to meet the application needs of more fields.

extrusion blow molding machine exporter---FAQs Guide

2.Besides the blow molding machine, what other services can Leshan provide?

3.How to optimize the efficiency of plastic blow molding machine?

4.How to improve the production capacity and speed of extrusion blow molding machine exporter?

5.How to adjust the production speed of extrusion blow molding machine exporter?

6.How to choose a extrusion blow molding machine exporter that suits your own craft?

7.How to choose a suitable extrusion blow molding machine exporter supplier?

8.Why does the blow molding machine make so much noise when it exhausts?

9.What are the safety standards for extrusion blow molding machine exporter?

10.What kind of bottle is suitable for making with the Leshan blow molding machine?

11.What waste materials will be generated during the production process of extrusion blow molding machine exporter?

1.Why does the temperature of the barrel exceed the set value when the extruder blow molding machine is working fully automatically?

Extrusion requires accurate control of the temperature of each area. The heat comes from the heating element on the one hand, and the internal shear heat on the other. So, you want to check whether the fan is broken, or the screw does not adapt to the plastic you choose, need to change the plastic or need to change the screw.You can also ask questions on Leshan's website, and their technicians can respond to your questions.

2.Besides the blow molding machine, what other services can Leshan provide?

Also provide close mold, auxiliary system, key engineering services.

3.How to optimize the efficiency of plastic blow molding machine?

It can improve the blowing process, improve the cooling water transportation of the mold, improve the machine action time, improve the shape of the cup to make the material tube become even, thus reducing the molding cycle time of the product.

4.How to improve the production capacity and speed of extrusion blow molding machine exporter?

We pay attention to user experience and product quality, and provide the best product quality and lowest production cost for cooperative customers.

1. Regular Maintenance: Regular maintenance of the blow molding machine is essential to ensure its smooth functioning and prevent breakdowns. This includes cleaning, lubricating, and replacing worn-out parts.

2. Use High-Quality Materials: The quality of the materials used in the blow molding process can greatly affect the production capacity and speed. Using high-quality materials can result in faster production and better quality products.

3. Optimize the Design: The design of the blow molding machine can also impact its production capacity and speed. Optimizing the design to reduce the number of steps and improve the efficiency of the process can increase the production speed.

4. Increase Automation: Automation can greatly improve the production capacity and speed of blow molding machines. Automated processes can reduce the need for manual labor and increase the accuracy and speed of production.

5. Use Advanced Technology: Upgrading to newer and more advanced blow molding technology can significantly improve the production capacity and speed. This includes using computer-controlled systems, advanced sensors, and other technologies that can optimize the production process.

6. Train Operators: Properly trained operators can greatly improve the efficiency and speed of the blow molding process. They should be trained in operating the machine, troubleshooting common issues, and performing routine maintenance.

7. Implement Lean Manufacturing Principles: Implementing lean manufacturing principles can help identify and eliminate waste in the production process, resulting in increased efficiency and speed.

8. Increase the Number of Cavities: Increasing the number of cavities in the blow molding machine can significantly increase the production capacity. This allows for more products to be produced in a single cycle, reducing the overall production time.

9. Optimize Cooling Time: The cooling time of the products can greatly impact the production speed. Optimizing the cooling time by using advanced cooling methods can reduce the overall production time.

10. Monitor and Analyze Production Data: Regularly monitoring and analyzing production data can help identify bottlenecks and areas for improvement. This can help optimize the production process and increase the production capacity and speed.

5.How to adjust the production speed of extrusion blow molding machine exporter?

Our extrusion blow molding machine exporter products undergo strict quality control to ensure customer satisfaction.

1. Check the machine settings: The first step in adjusting the production speed of a blow molding machine is to check the machine settings. Make sure that the machine is set to the desired production speed and that all the necessary adjustments have been made.

2. Adjust the air pressure: The air pressure is a crucial factor in the production speed of a blow molding machine. Increasing the air pressure can help to speed up the production process, while decreasing it can slow it down. Adjust the air pressure according to the desired production speed.

3. Change the mold: The size and shape of the mold can also affect the production speed. A larger or more complex mold will take longer to produce, while a smaller and simpler mold will speed up the production process. Consider changing the mold to one that is more suitable for the desired production speed.

4. Increase or decrease the parison size: The parison is the hollow tube of plastic that is formed in the machine and then blown into the mold. Adjusting the size of the parison can also affect the production speed. Increasing the parison size will result in a larger product and slower production, while decreasing the parison size will result in a smaller product and faster production.

5. Adjust the cooling time: The cooling time is the amount of time the product spends in the mold to solidify. Increasing the cooling time will slow down the production speed, while decreasing it will speed it up. Adjust the cooling time according to the desired production speed.

6. Check for any mechanical issues: If the production speed is not adjusting as expected, it is important to check for any mechanical issues with the machine. Make sure that all the components are functioning properly and that there are no obstructions or malfunctions that could be slowing down the production speed.

7. Test and adjust: Once all the necessary adjustments have been made, run a test production to see if the desired speed has been achieved. If not, make further adjustments until the desired production speed is reached.

It is important to note that adjusting the production speed of a blow molding machine may require some trial and error. It is recommended to make small adjustments at a time and test the results before making further adjustments.

6.How to choose a extrusion blow molding machine exporter that suits your own craft?

We continue to improve extrusion blow molding machine exporter products and processes to improve efficiency.

1. Determine the type of blow molding process: There are three main types of blow molding processes - extrusion blow molding, injection blow molding, and stretch blow molding. Each process has its own advantages and is suitable for different types of products. Determine which process is most suitable for your product before choosing a machine.

2. Consider the size and shape of your product: Blow molding machines come in different sizes and have different capabilities. Consider the size and shape of your product to determine the size and type of machine you need. For example, if you are producing large containers, you will need a machine with a larger clamping force and a larger mold size.

3. Look for a reputable manufacturer: It is important to choose a reputable manufacturer when buying a blow molding machine. Look for manufacturers with a good track record and positive reviews from other customers. This will ensure that you get a high-quality machine that is reliable and durable.

4. Check the machine's features and capabilities: Different blow molding machines come with different features and capabilities. Some machines may have advanced features such as multi-layer co-extrusion, while others may have simpler features. Consider the features that are important for your production process and choose a machine that meets your requirements.

5. Consider the production volume: The production volume of your product will also play a role in choosing the right blow molding machine. If you have a high production volume, you will need a machine with a higher output and faster cycle times. On the other hand, if you have a lower production volume, a smaller machine with a lower output may be more suitable.

6. Look for after-sales support: It is important to choose a manufacturer that offers good after-sales support. This includes technical support, spare parts availability, and maintenance services. A good after-sales support system will ensure that your machine runs smoothly and any issues are resolved quickly.

7. Consider your budget: Blow molding machines can be a significant investment, so it is important to consider your budget when choosing a machine. However, it is also important to keep in mind that a cheaper machine may not always be the best option in terms of quality and performance. Consider the long-term benefits and ROI when making your decision.

8. Test the machine: If possible, visit the manufacturer's facility and test the machine before making a purchase. This will give you a better understanding of the machine's capabilities and help you make an informed decision.

9. Seek expert advice: If you are new to blow molding, it is advisable to seek advice from experts in the industry. They can provide valuable insights and help you choose a machine that is suitable for your specific needs.

10. Consider future growth: It is important to consider your future growth plans when choosing a blow molding machine. Choose a machine that can accommodate your future production needs and can be upgraded if necessary. This will save you from having to invest in a new machine in the future.

7.How to choose a suitable extrusion blow molding machine exporter supplier?

We adhere to the principle of quality first and have a complete production quality management system and quality inspection process.

1. Research and compare different suppliers: Start by researching and comparing different blow molding machine suppliers. Look for their experience, reputation, and customer reviews to get an idea of their reliability and quality of products.

2. Consider the type of blow molding machine you need: There are different types of blow molding machines available, such as extrusion blow molding, injection blow molding, and stretch blow molding. Choose a supplier who specializes in the type of machine you need.

3. Quality of machines: The quality of the blow molding machine is crucial for its performance and durability. Look for suppliers who use high-quality materials and have a strict quality control process in place.

4. Customization options: If you have specific requirements for your blow molding machine, look for a supplier who offers customization options. This will ensure that the machine is tailored to your needs and can meet your production requirements.

5. After-sales support: A good supplier should offer after-sales support, including installation, training, and maintenance services. This will ensure that your machine runs smoothly and any issues are resolved promptly.

6. Price and payment terms: Compare the prices of different suppliers and choose one that offers competitive pricing without compromising on quality. Also, consider the payment terms and choose a supplier who offers flexible payment options.

7. Technical support: Blow molding machines are complex equipment, and it is essential to have technical support in case of any issues. Choose a supplier who offers technical support and has a team of experienced technicians.

8. Delivery time: If you have a tight production schedule, it is crucial to choose a supplier who can deliver the machine within the specified time frame. Inquire about their delivery time and make sure it aligns with your production schedule.

9. Warranty and service contracts: A good supplier should offer a warranty for their machines and also provide service contracts for regular maintenance. This will ensure that your machine remains in good condition and has a longer lifespan.

10. Communication and responsiveness: Choose a supplier who has good communication and is responsive to your queries and concerns. This will ensure a smooth and hassle-free buying experience.

8.Why does the blow molding machine make so much noise when it exhausts?

The exhaust valve is blocked or the exhaust valve and exhaust pipe are too small.

9.What are the safety standards for extrusion blow molding machine exporter?

We are a new extrusion blow molding machine exporter manufacturer.

1. Electrical Safety: Blow molding machines should comply with all relevant electrical safety standards, such as the National Electrical Code (NEC) and the International Electrotechnical Commission (IEC) standards.

2. Machine Guarding: All moving parts of the machine should be guarded to prevent accidental contact and injuries. The guards should be securely fixed and not easily removable.

3. Emergency Stop: The machine should have an easily accessible emergency stop button that can quickly shut down the machine in case of an emergency.

4. Lockout/Tagout: The machine should have a lockout/tagout system in place to prevent accidental start-up during maintenance or repair.

5. Pressure Relief: Blow molding machines use high-pressure air to mold plastic, so they should have a pressure relief system in place to prevent over-pressurization and potential explosions.

6. Material Handling: The machine should have a safe and efficient material handling system to prevent injuries and accidents during the loading and unloading of materials.

7. Noise Control: Blow molding machines can produce high levels of noise, so they should have noise control measures in place to protect workers' hearing.

8. Fire Safety: The machine should have fire safety measures in place, such as fire extinguishers and fire alarms, to prevent and control fires.

9. Operator Training: All operators should receive proper training on how to operate the machine safely and be aware of potential hazards.

10. Regular Maintenance: The machine should undergo regular maintenance and inspections to ensure it is in good working condition and meets all safety standards.

10.What kind of bottle is suitable for making with the Leshan blow molding machine?

Such as washing supplies, hotel supplies, personal supplies, food, medicine, pesticides, wide-mouth bottles and other PETG and PVC packaging industries, etc., can be produced by Leshan blow molding machine.

11.What waste materials will be generated during the production process of extrusion blow molding machine exporter?

Our company has many years of extrusion blow molding machine exporter experience and expertise.

1. Plastic waste: Blow molding machines use plastic materials such as polyethylene (PE), polypropylene (PP), and polyethylene terephthalate (PET) to produce plastic products. These materials are often left as waste after the production process.

2. Scrap plastic: During the production process, there may be excess or defective plastic parts that are not suitable for use. These scraps are considered waste and need to be properly disposed of.

3. Residual materials: Some materials, such as colorants and additives, may be left over after the production process. These materials may also be considered waste and need to be disposed of properly.

4. Packaging waste: Blow molding machines often require packaging materials such as cardboard boxes, plastic bags, and bubble wrap for shipping and storage. These materials can generate waste during the production process.

5. Cleaning waste: Blow molding machines need to be cleaned regularly to maintain their efficiency. This process can generate waste such as cleaning agents, rags, and other materials.

6. Energy waste: The production process of blow molding machines requires energy, which can result in waste in the form of emissions and by-products.

7. Water waste: Some blow molding machines use water for cooling or lubrication purposes. This water may become contaminated during the production process and need to be properly treated before disposal.

8. Metal waste: Some blow molding machines may use metal components, such as molds and machine parts, which can generate metal waste during the production process.

9. Hazardous waste: Some materials used in blow molding machines, such as solvents and chemicals, may be hazardous and require special handling and disposal methods.

10. Electronic waste: Blow molding machines may also contain electronic components that can become obsolete or damaged during the production process, resulting in electronic waste.