Extrusion blow molded tube

Extrusion blow molded tube

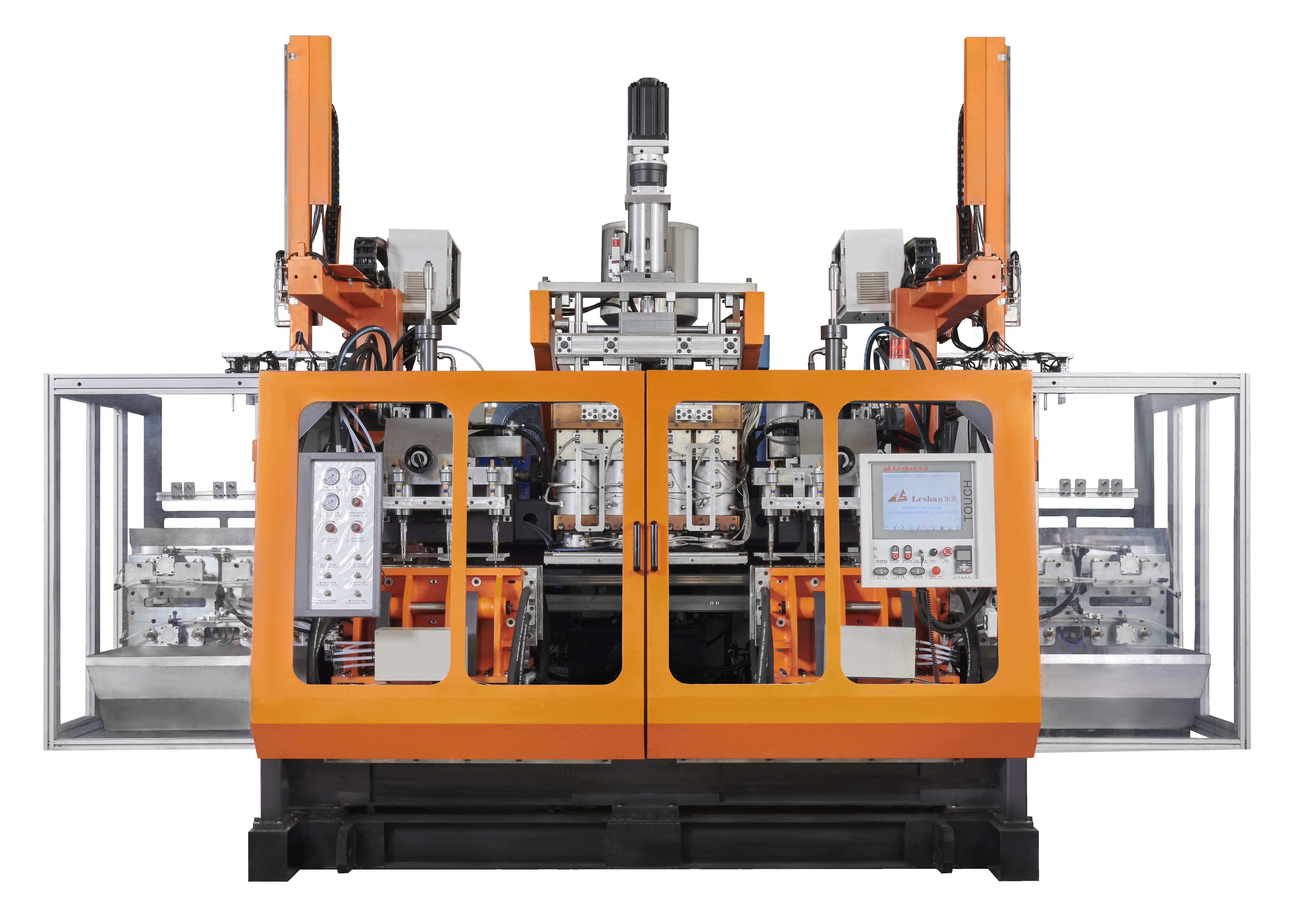

Leshan Intelligent Equipment Company is located in Foshan, near Shenzhen and Guangzhou, specializing in the production of Hydraulic Blow Molding Machine, All-Electric PET Blow Molding Machine,Cleaning bottle blow molding machine,Blowing Mould & Injection Mould,Engine oil bottle blow molding machine,PET Machine,Chemical barrel blow molding machine,Irregular shape product blow molding machine,multi-layer coextrusion blow molding machine,athlon series hydraulic machine,Milk bottle blow molding machine and other equipment. We have a history of over 20 years in the blow molding machine industry.Our company also brought in the Germanic technical 3D scanner which is exclusive used for mold-designing . The advanced Leshan Blow Molding Machine working with the superior Leshan Mould makes the production speed faster and the production quality the topest.

LESHAN has Vertical CNC gantry machining-center,Four axis CNC machining-center,Pentahedron gantry machining center,Numerical-controlled cutting machine and other specialized equipment. We are also armed with comprehensive strength such as strong R&D power,production marketing,technical support,etc..We have awarded the title of "Guangdong Hi-tech enterprise" ,the honor of "Brand-name products in Guangdong Province" and "Guangdong Province Well-known Trademark".

| Parameter | Information |

| Product Name | extrusion blow molded tube |

| Brand Name | Leshan |

| Place of Origin | Foshan,Guangdong |

| PLC Brand | Siemens |

| Core Components | Motor,Bearing,PLC,Pump,Engine...etc |

| Warranty | 1year |

| Plastic Processed | HDPE,EVA,PVC,PE,PP,PA,Polystyrene...etc |

| Application | Bottle |

| Port | ShunDe/GuangZhou/ShenZhen China |

| MOQ | 1 Set |

| Export Country | Russia, Australia, Poland,Sudan,Denmark,Isle of Man...etc |

| Export region | Europe,Oceania,Asia... |

| Certification | ISO 9001,CE...etc |

| Automatic | Yes |

| Screw L/D Ratio | 24 |

| Packaging Details | Standard exporting machine packing with plastic film |

| Color | Customized |

| Accumulator Capacity(L) | 100 L |

| Service | Online support... |

| Supply Ability | 500 Set/Sets per Month |

| Lead time (days) | 70 (To be negotiated) |

Please note: The above table data is for reference only. For specific information, please contact us.

extrusion blow molded tube is an indispensable and important equipment in modern plastic manufacturing industry, and its characteristics are constantly being improved and developed. Future blow molding machines will be more intelligent, energy-saving and environmentally friendly, and have more additional functions to meet changing market demands. At the same time, with the introduction of new degradable plastics, blow molding machines will also adapt to the processing of new materials, promoting the development of the plastic products industry in a more environmentally friendly and sustainable direction.

extrusion blow molded tube---FAQs Guide

2.Is there a limit to the size range of extrusion blow molded tube?

3.Can I make milk bottle on this machine?

4.What is the after-sales service for extrusion blow molded tube?

5.What are the dimensions and weight of the extrusion blow molded tube?

6.What types of blow molding machines are there?

7.How to solve the malfunction of the extrusion blow molded tube?

8.What is a blow molding machine?

9.About extrusion blow molded tube,Do you provide samples? ls it free or extra?

10.What products are typically manufactured using extrusion blow molded tube?

11.What are the steps for cleaning and maintaining a extrusion blow molded tube?

1.How does the extrusion blow molding process differ from injection blow molding, and what types of products are typically produced using each method?

We have been working hard to improve service quality and meet customer needs.

Extrusion blow molding and injection blow molding are two different processes used to manufacture plastic products. While both methods involve melting plastic and shaping it into a desired form, there are some key differences between the two.

Extrusion blow molding is a process in which a molten tube of plastic, called a parison, is extruded through a die and then inflated to form a hollow product. The parison is then cooled and the mold opens to release the finished product. This process is commonly used to produce bottles, containers, and other hollow objects.

On the other hand, injection blow molding involves injecting molten plastic into a mold cavity, where it is then cooled and solidified. The mold then opens to release the finished product. This process is commonly used to produce small, complex, and precise products such as medical devices, pharmaceutical packaging, and small bottles.

One of the main differences between the two processes is the way the plastic is shaped. In extrusion blow molding, the plastic is shaped by the inflation of the parison, while in injection blow molding, the plastic is shaped by the mold cavity.

Another difference is the type of molds used. In extrusion blow molding, the molds are typically made of two halves that come together to form the desired shape. In injection blow molding, the molds are usually made of a single piece that is opened and closed to release the product.

The type of plastic used also differs between the two processes. Extrusion blow molding is typically used for high-density polyethylene (HDPE) and polyethylene terephthalate (PET) plastics, while injection blow molding is commonly used for polypropylene (PP) and polyethylene (PE) plastics.

In terms of product applications, extrusion blow molding is commonly used for larger, more simple products such as bottles and containers, while injection blow molding is used for smaller, more complex products such as medical devices and pharmaceutical packaging.

In summary, extrusion blow molding and injection blow molding are two different processes used to manufacture plastic products. While both methods involve melting plastic and shaping it into a desired form, they differ in the way the plastic is shaped, the type of molds used, and the types of products produced.

2.Is there a limit to the size range of extrusion blow molded tube?

We continue to invest in research and development and continue to launch innovative products.

Yes, there is a limit to the size range of blow molding machines. The size range of blow molding machines is typically determined by the maximum volume of the mold cavity and the maximum clamping force of the machine. The maximum volume of the mold cavity can range from a few milliliters to several liters, while the maximum clamping force can range from a few tons to several hundred tons.

Therefore, the size range of blow molding machines can vary greatly depending on the specific machine and its capabilities. Generally, blow molding machines are used to produce plastic products ranging from small bottles and containers to larger items such as automotive parts and large industrial containers.

3.Can I make milk bottle on this machine?

Yes, you can. Milk bottle,detergent bottle,pattern pot are available on the machine.

4.What is the after-sales service for extrusion blow molded tube?

We are centered on customers and always pay attention to customers' needs for extrusion blow molded tube products.

The after-sales service for blow molding machines typically includes:

1. Technical support: This includes troubleshooting assistance, repair guidance, and advice on machine maintenance and operation.

2. Spare parts supply: The manufacturer or supplier should have a stock of spare parts for the blow molding machine, and be able to provide them quickly when needed.

3. Training: The manufacturer or supplier may offer training programs for operators and maintenance personnel to ensure proper use and maintenance of the machine.

4. Warranty: Most blow molding machines come with a warranty period, during which any defects or malfunctions will be repaired or replaced by the manufacturer or supplier.

5. On-site support: In case of major issues or breakdowns, the manufacturer or supplier may send a technician to the customer's site to provide on-site support and repairs.

6. Upgrades and improvements: The manufacturer or supplier may offer upgrades or improvements to the machine to enhance its performance or add new features.

7. Customer service: A good after-sales service should also include prompt and helpful customer service to address any concerns or questions the customer may have.

Overall, the after-sales service for blow molding machines should ensure that the customer's machine is running smoothly and efficiently, and any issues are resolved quickly to minimize downtime.

5.What are the dimensions and weight of the extrusion blow molded tube?

We are committed to providing personalized solutions and established long -term strategic cooperative relationships with customers.

The dimensions and weight of a blow molding machine can vary depending on the specific model and manufacturer. However, a general estimate for a standard blow molding machine is approximately 10 feet in length, 6 feet in width, and 8 feet in height. The weight can range from 5,000 to 10,000 pounds.

6.What types of blow molding machines are there?

We should have a stable supply chain and logistics capabilities, and provide customers with high -quality, low -priced extrusion blow molded tube products.

1. Extrusion blow molding machine: This type of machine uses a continuous extrusion process to produce hollow plastic products, such as bottles, containers, and tanks.

2. Injection blow molding machine: This machine combines the processes of injection molding and blow molding to produce small, complex, and precise plastic products, such as medical devices and electronic components.

3. Stretch blow molding machine: This machine uses a two-stage process to produce high-quality, lightweight bottles and containers from PET (polyethylene terephthalate) material.

4. Reheat stretch blow molding machine: This type of machine is similar to the stretch blow molding machine, but it uses preforms (partially formed bottles) instead of raw material to produce bottles and containers.

5. Rotational blow molding machine: This machine uses a rotating mold to produce large, hollow plastic products, such as tanks, drums, and toys.

6. Shuttle blow molding machine: This machine has a shuttle system that moves the mold back and forth, allowing for the production of larger and more complex products.

7. Injection stretch blow molding machine: This machine combines the processes of injection molding and stretch blow molding to produce high-quality, lightweight bottles and containers from PET material.

8. Accumulator blow molding machine: This machine uses an accumulator to store molten plastic, which is then used to produce large and complex products, such as automotive parts and industrial containers.

9. Continuous extrusion blow molding machine: This machine uses a continuous extrusion process to produce long, tubular plastic products, such as pipes and tubes.

10. Co-extrusion blow molding machine: This machine uses multiple extruders to produce products with multiple layers, allowing for the production of complex and multi-functional products.

7.How to solve the malfunction of the extrusion blow molded tube?

As one of the top extrusion blow molded tube manufacturers in China, we take this very seriously.

1. Check the power supply: Make sure the machine is properly connected to a stable power source. If there is a power surge or fluctuation, it can cause the machine to malfunction.

2. Inspect the air supply: The blow molding machine requires a steady supply of compressed air to function properly. Check the air compressor and make sure it is providing enough pressure and volume.

3. Check the temperature settings: The temperature of the machine's heating elements must be set correctly for the plastic to melt and form properly. Make sure the temperature settings are appropriate for the type of plastic being used.

4. Clean and lubricate the machine: Over time, dust, debris, and residue can build up on the machine, causing it to malfunction. Clean and lubricate all moving parts to ensure smooth operation.

5. Check for worn or damaged parts: Inspect all parts of the machine for wear and tear. Replace any damaged or worn parts to prevent further malfunctions.

6. Adjust the mold: If the product being produced is not forming correctly, the mold may need to be adjusted. Make sure the mold is properly aligned and tightened.

7. Consult the manual: If the above steps do not solve the problem, consult the machine's manual for troubleshooting tips and solutions specific to your machine.

8. Call a professional: If the problem persists, it may be best to call a professional technician to diagnose and repair the machine. Attempting to fix complex issues without proper knowledge and training can cause further damage.

8.What is a blow molding machine?

We maintain a stable growth through reasonable capital operations, focus on industry development trends and cutting -edge technologies, and focus on product quality and safety performance.

A blow molding machine is a manufacturing machine used to produce hollow plastic parts or containers by inflating a heated plastic tube or parison inside a mold until it takes the shape of the mold cavity. The process involves melting plastic resin and extruding it into a hollow tube, which is then clamped into a mold and inflated with compressed air until it conforms to the shape of the mold.

This process is commonly used to produce bottles, containers, and other hollow plastic products. Blow molding machines can be either extrusion blow molding machines or injection blow molding machines, depending on the method used to create the parison.

9.About extrusion blow molded tube,Do you provide samples? ls it free or extra?

Yes,we could offer you the sample.But it's not free.You need to pay for the sample and the cost of freight.

10.What products are typically manufactured using extrusion blow molded tube?

Our products & services cover a wide range of areas and meet the needs of different fields.

1. Plastic bottles and containers: Blow molding machines are commonly used to produce plastic bottles and containers of various sizes and shapes, such as water bottles, shampoo bottles, and food containers.

2. Automotive components: Many automotive parts, such as fuel tanks, air ducts, and bumpers, are manufactured using blow molding machines.

3. Toys: Blow molding machines are used to produce a wide range of plastic toys, including balls, action figures, and building blocks.

4. Household products: Items such as laundry baskets, storage bins, and trash cans are often made using blow molding machines.

5. Medical equipment: Many medical devices, such as IV bags, syringes, and respiratory masks, are manufactured using blow molding machines.

6. Packaging materials: Blow molding machines are used to produce packaging materials such as plastic bags, pouches, and containers for food and other consumer products.

7. Industrial and agricultural products: Large containers, drums, and tanks used in industrial and agricultural settings are often made using blow molding machines.

8. Sports equipment: Blow molding machines are used to produce a variety of sports equipment, including footballs, soccer balls, and hockey sticks.

9. Furniture: Some types of furniture, such as chairs and tables, are made using blow molding machines to create lightweight and durable plastic components.

10. Construction materials: Blow molding machines are used to produce pipes, tubes, and other construction materials made from plastic.

11.What are the steps for cleaning and maintaining a extrusion blow molded tube?

We adhere to the principle of integrity and transparency, and establish long -term relationships with partners, and we attach great importance to this detail.

1. Shut off and unplug the machine: Before starting any cleaning or maintenance, make sure the machine is turned off and unplugged to avoid any accidents.

2. Remove excess material: Use a scraper or a brush to remove any excess material from the machine, including the mold, extruder, and die head.

3. Disassemble the machine: Depending on the type of blow molding machine, you may need to disassemble certain parts to access all the areas that need cleaning. Refer to the manufacturer's manual for specific instructions.

4. Clean the mold: Use a mild detergent and warm water to clean the mold. Make sure to remove any residue or buildup from the mold surface. You can also use a specialized mold cleaner for tougher stains.

5. Clean the extruder and die head: Use a brush or scraper to remove any residue or buildup from the extruder and die head. You can also use a specialized cleaner for these parts.

6. Check and clean the cooling system: The cooling system is essential for maintaining the temperature of the machine. Check for any clogs or buildup in the cooling channels and clean them with a brush or compressed air.

7. Lubricate moving parts: Use a lubricant recommended by the manufacturer to lubricate all the moving parts of the machine. This will help prevent wear and tear and ensure smooth operation.

8. Inspect and replace worn parts: Check all the parts of the machine for any signs of wear and tear. Replace any damaged or worn parts to ensure the machine's optimal performance.

9. Reassemble the machine: Once all the parts are cleaned and inspected, reassemble the machine following the manufacturer's instructions.

10. Test the machine: Before using the machine again, run a test cycle to ensure everything is working correctly.

11. Regular maintenance: To keep the machine in good working condition, it is essential to perform regular maintenance tasks such as cleaning, lubricating, and inspecting the machine. Refer to the manufacturer's manual for a recommended maintenance schedule.

Tags: 5 liters blow molding machine , top blow molding machine