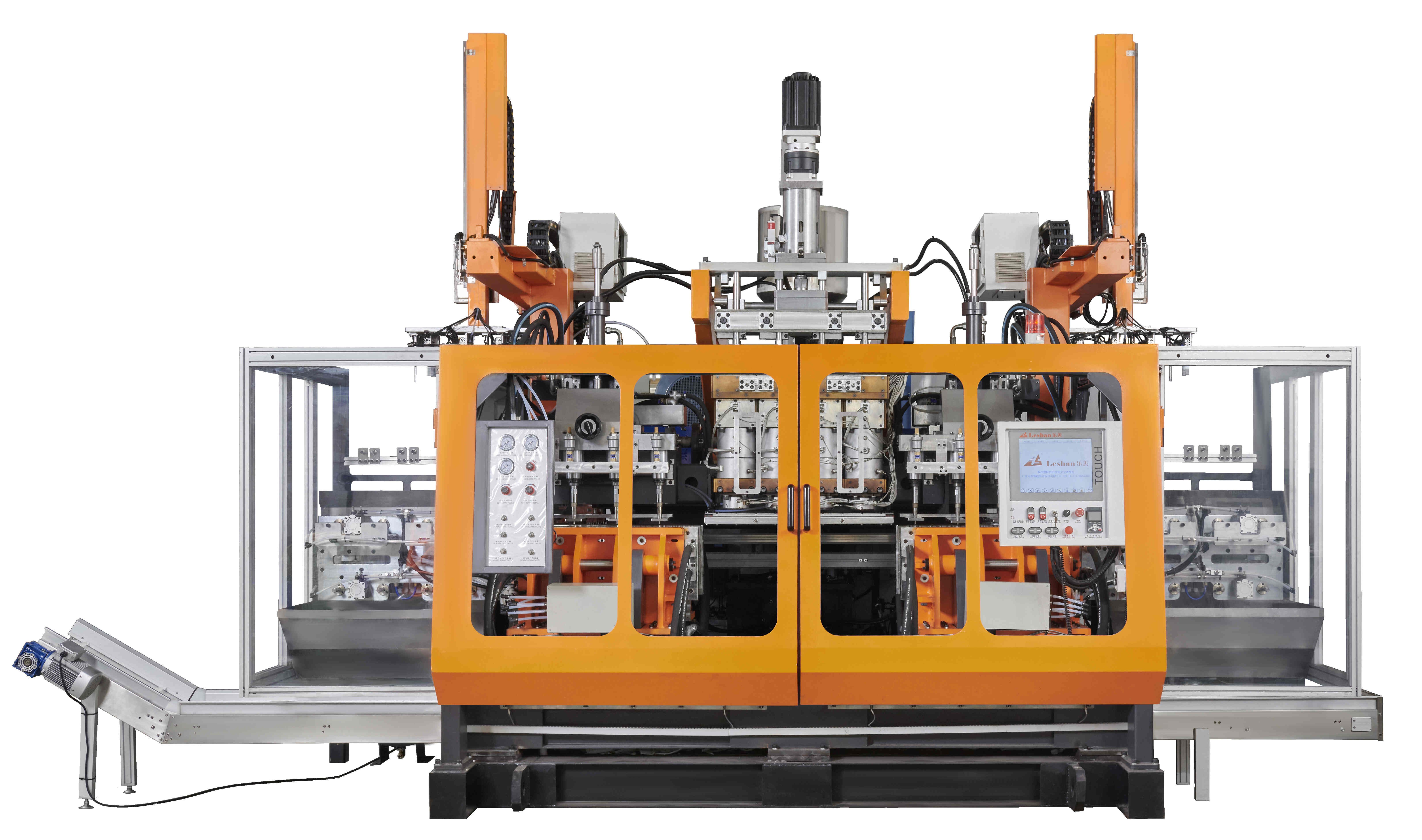

Continuos Extrusion Blow Molding

Continuos Extrusion Blow Molding

Guangdong Leshan Intelligent Equipment Corp.,Ltd is located in Foshan, near Shenzhen and Guangzhou, specializing in the production of Hydraulic Blow Molding Machine, All-Electric PET Blow Molding Machine,Blowing Mould & Injection Mould,Auxiliary machine,Chemical barrel blow molding machine,Irregular shape product blow molding machine,Daily chemistry bottle blow molding machine,Cleaning bottle blow molding machine,Milk bottle blow molding machine,Engine oil bottle blow molding machine,athlon series hydraulic machine,Extrusion Die Head,Food bottle blow molding machine and other equipment. We have a history of over 20 years in the blow molding machine industry.Our company also brought in the Germanic technical 3D scanner which is exclusive used for mold-designing . The advanced Leshan Blow Molding Machine working with the superior Leshan Mould makes the production speed faster and the production quality the topest.

LESHAN has Numerical-controlled cutting machine,Four axis CNC machining-center,Vertical CNC gantry machining-center,Pentahedron gantry machining center and other specialized equipment. We are also armed with comprehensive strength such as strong R&D power,production marketing,technical support,etc..We have awarded the title of "Guangdong Hi-tech enterprise" ,the honor of "Brand-name products in Guangdong Province" and "Guangdong Province Well-known Trademark".

| Parameter | Information |

| Product Name | continuos extrusion blow molding |

| Place of Origin | Foshan,Guangdong |

| Brand Name | Leshan |

| Condition | New |

| Video outgoing-inspection | Provided |

| Machinery Test Report | Provided |

| Warranty of core components | 1 year |

| Warranty | 1year |

| Port | ShunDe/GuangZhou/ShenZhen China |

| Application | Bottle |

| Core Components | Gearbox,Bearing,Motor,Pump,Pressure vessel,Gear...etc |

| Color | customized |

| Plastic Processed | PE,ABS,PP,HDPE,PVC,EVA,Polystyrene...etc |

| Certification | CE,ISO9001:2012... |

| PLC Brand | Siemens |

| Packaging Details | Standard exporting machine packing with plastic film |

| Service | Free spare parts |

| Automation | Automation |

| Supply Ability | 500 Set/Sets per year |

| Lead time (days) | 70 (To be negotiated) |

Please note: The above table data is for reference only. For specific information, please contact us.

continuos extrusion blow molding also offer flexibility and scalability. It can adjust the production process and parameters according to production needs to meet different product requirements. At the same time, the blow molding machine also has extension functions. By adding additional devices, it can realize bottle mouth separation, label attachment and other processing to meet the application needs of more fields.

continuos extrusion blow molding---FAQs Guide

2.How to choose a suitable continuos extrusion blow molding supplier?

3.What waste materials will be generated during the production process of continuos extrusion blow molding?

4.What energy-saving measures are there for continuos extrusion blow molding?

5.How to control temperature and pressure during the production process of continuos extrusion blow molding?

6.What are the precautions for operating a continuos extrusion blow molding?

7.How does the pressure system of a continuos extrusion blow molding work?

8.Is there a limit to the size range of continuos extrusion blow molding?

1.What is the operating cost of a continuos extrusion blow molding?

We attach importance to the innovation ability and team spirit of employees, have advanced R & D facilities and laboratories, and have a good quality management system.

The operating cost of a blow molding machine can vary depending on factors such as the size and type of machine, the materials being used, and the production volume. However, some common operating costs include:

1. Energy costs: Blow molding machines require a significant amount of energy to operate, including electricity for heating and cooling processes. The cost of energy can vary depending on the location and the efficiency of the machine.

2. Labor costs: The cost of labor includes the wages of operators and technicians who run the machine, as well as any maintenance or repair personnel.

3. Material costs: The cost of materials, such as plastic resins, can vary depending on the type and quality of the material being used.

4. Maintenance and repair costs: Regular maintenance and occasional repairs are necessary to keep the machine running smoothly, and these costs should be factored into the overall operating cost.

5. Overhead costs: This includes expenses such as rent, insurance, and administrative costs that are necessary for the operation of the machine.

Overall, the operating cost of a blow molding machine can range from a few hundred dollars per day for a small machine to thousands of dollars per day for a large, high-volume machine.

2.How to choose a suitable continuos extrusion blow molding supplier?

We adhere to the principle of quality first and have a complete production quality management system and quality inspection process.

1. Research and compare different suppliers: Start by researching and comparing different blow molding machine suppliers. Look for their experience, reputation, and customer reviews to get an idea of their reliability and quality of products.

2. Consider the type of blow molding machine you need: There are different types of blow molding machines available, such as extrusion blow molding, injection blow molding, and stretch blow molding. Choose a supplier who specializes in the type of machine you need.

3. Quality of machines: The quality of the blow molding machine is crucial for its performance and durability. Look for suppliers who use high-quality materials and have a strict quality control process in place.

4. Customization options: If you have specific requirements for your blow molding machine, look for a supplier who offers customization options. This will ensure that the machine is tailored to your needs and can meet your production requirements.

5. After-sales support: A good supplier should offer after-sales support, including installation, training, and maintenance services. This will ensure that your machine runs smoothly and any issues are resolved promptly.

6. Price and payment terms: Compare the prices of different suppliers and choose one that offers competitive pricing without compromising on quality. Also, consider the payment terms and choose a supplier who offers flexible payment options.

7. Technical support: Blow molding machines are complex equipment, and it is essential to have technical support in case of any issues. Choose a supplier who offers technical support and has a team of experienced technicians.

8. Delivery time: If you have a tight production schedule, it is crucial to choose a supplier who can deliver the machine within the specified time frame. Inquire about their delivery time and make sure it aligns with your production schedule.

9. Warranty and service contracts: A good supplier should offer a warranty for their machines and also provide service contracts for regular maintenance. This will ensure that your machine remains in good condition and has a longer lifespan.

10. Communication and responsiveness: Choose a supplier who has good communication and is responsive to your queries and concerns. This will ensure a smooth and hassle-free buying experience.

3.What waste materials will be generated during the production process of continuos extrusion blow molding?

Our company has many years of continuos extrusion blow molding experience and expertise.

1. Plastic waste: Blow molding machines use plastic materials such as polyethylene (PE), polypropylene (PP), and polyethylene terephthalate (PET) to produce plastic products. These materials are often left as waste after the production process.

2. Scrap plastic: During the production process, there may be excess or defective plastic parts that are not suitable for use. These scraps are considered waste and need to be properly disposed of.

3. Residual materials: Some materials, such as colorants and additives, may be left over after the production process. These materials may also be considered waste and need to be disposed of properly.

4. Packaging waste: Blow molding machines often require packaging materials such as cardboard boxes, plastic bags, and bubble wrap for shipping and storage. These materials can generate waste during the production process.

5. Cleaning waste: Blow molding machines need to be cleaned regularly to maintain their efficiency. This process can generate waste such as cleaning agents, rags, and other materials.

6. Energy waste: The production process of blow molding machines requires energy, which can result in waste in the form of emissions and by-products.

7. Water waste: Some blow molding machines use water for cooling or lubrication purposes. This water may become contaminated during the production process and need to be properly treated before disposal.

8. Metal waste: Some blow molding machines may use metal components, such as molds and machine parts, which can generate metal waste during the production process.

9. Hazardous waste: Some materials used in blow molding machines, such as solvents and chemicals, may be hazardous and require special handling and disposal methods.

10. Electronic waste: Blow molding machines may also contain electronic components that can become obsolete or damaged during the production process, resulting in electronic waste.

4.What energy-saving measures are there for continuos extrusion blow molding?

I have a comprehensive after -sales service system, which can pay attention to market trends in time and adjust our strategy in a timely manner.

1. Use energy-efficient motors: Switching to energy-efficient motors can significantly reduce the energy consumption of a blow molding machine. These motors use less electricity and produce less heat, resulting in lower energy costs.

2. Optimize air pressure: Adjusting the air pressure to the minimum required level can reduce the energy consumption of the compressor and save energy.

3. Use variable frequency drives (VFDs): VFDs can adjust the speed of the motor to match the required output, reducing energy consumption and wear on the motor.

4. Insulate heating elements: Insulating the heating elements of the machine can reduce heat loss and improve energy efficiency.

5. Use LED lighting: Replacing traditional lighting with energy-efficient LED lights can reduce energy consumption and save on electricity costs.

6. Regular maintenance: Proper maintenance of the machine, including cleaning and lubrication, can improve its efficiency and reduce energy consumption.

7. Implement a shutdown schedule: Setting a shutdown schedule for the machine when it is not in use can save energy and reduce wear and tear on the machine.

8. Use energy-efficient materials: Using energy-efficient materials, such as lightweight plastics, can reduce the energy required to produce and transport the products.

9. Implement a heat recovery system: A heat recovery system can capture and reuse the heat generated during the blow molding process, reducing the energy needed to heat the material.

10. Invest in a high-efficiency machine: Upgrading to a newer, more energy-efficient blow molding machine can result in significant energy savings in the long run.

5.How to control temperature and pressure during the production process of continuos extrusion blow molding?

We focus on our customers' needs and strive to meet their expectations, so we take this very seriously.

1. Use a temperature controller: A temperature controller is an essential tool for controlling the temperature during the production process of blow molding machines. It allows you to set and maintain the desired temperature for the different stages of the process.

2. Monitor the temperature regularly: It is important to monitor the temperature of the machine regularly to ensure that it is within the desired range. This can be done using a thermometer or a temperature sensor.

3. Adjust the temperature settings: Depending on the type of material being used and the stage of the production process, the temperature settings may need to be adjusted. For example, a higher temperature may be required for melting the plastic, while a lower temperature may be needed for cooling the molded product.

4. Use a cooling system: To control the temperature during the cooling stage, a cooling system can be used. This can be in the form of a water chiller or a cooling tower, which helps to maintain a consistent temperature for the molded product.

5. Use a pressure regulator: A pressure regulator is used to control the pressure inside the machine. This is important for ensuring that the plastic is evenly distributed and that the final product has the desired shape and thickness.

6. Monitor the pressure: Just like temperature, it is important to monitor the pressure inside the machine regularly. This can be done using a pressure gauge or a pressure sensor.

7. Adjust the pressure settings: Depending on the type of material and the desired product, the pressure settings may need to be adjusted. This can be done manually or through the use of an automated pressure control system.

8. Use safety valves: Safety valves are important for maintaining the pressure within safe limits. They help to prevent any accidents or damage to the machine.

9. Train operators: It is important to train operators on how to control the temperature and pressure during the production process. They should be familiar with the different settings and know how to make adjustments when necessary.

10. Regular maintenance: Regular maintenance of the machine is crucial for ensuring that the temperature and pressure control systems are functioning properly. This will help to prevent any unexpected issues during the production process.

6.What are the precautions for operating a continuos extrusion blow molding?

We operate our continuos extrusion blow molding business with integrity and honesty.

1. Read the manual: Before operating the blow molding machine, it is important to thoroughly read and understand the manual provided by the manufacturer. This will help you understand the machine's capabilities, limitations, and safety precautions.

2. Wear appropriate protective gear: Always wear appropriate protective gear, such as safety glasses, gloves, and earplugs, when operating the blow molding machine. This will protect you from any potential hazards.

3. Keep the work area clean: Make sure the work area is clean and free of any debris or obstructions. This will prevent accidents and ensure smooth operation of the machine.

4. Check the machine before use: Before starting the machine, check for any loose or damaged parts. Make sure all the safety guards are in place and functioning properly.

5. Use the correct materials: Use only the materials recommended by the manufacturer for the blow molding machine. Using the wrong materials can damage the machine and pose a safety risk.

6. Follow proper loading procedures: When loading materials into the machine, make sure to follow the proper procedures outlined in the manual. This will ensure the materials are loaded correctly and prevent any accidents.

7. Do not touch moving parts: Never touch any moving parts of the machine while it is in operation. This includes the mold, extruder, and other moving components.

8. Keep hands and clothing away from the machine: Keep your hands and clothing away from the machine while it is in operation. Loose clothing or jewelry can get caught in the machine and cause serious injuries.

9. Do not leave the machine unattended: Always stay with the machine while it is in operation. If you need to leave the machine for any reason, make sure to turn it off and wait for it to come to a complete stop before leaving.

10. Shut down properly: When finished using the machine, shut it down properly following the manufacturer's instructions. This will help prevent any accidents and prolong the life of the machine.

7.How does the pressure system of a continuos extrusion blow molding work?

We have a first -class management team, and we pay attention to teamwork to achieve common goals.

The pressure system of a blow molding machine is responsible for creating and maintaining the necessary pressure to inflate the parison (hollow tube of plastic) and shape it into the desired product. This system typically consists of three main components: the air compressor, the accumulator, and the pressure regulator.

1. Air Compressor: The air compressor is the heart of the pressure system. It supplies compressed air to the machine at a high pressure, typically between 100-150 psi. This compressed air is stored in a tank and then fed into the accumulator.

2. Accumulator: The accumulator is a large tank that stores the compressed air from the air compressor. It acts as a buffer, ensuring a steady supply of air to the machine. The accumulator also helps to regulate the pressure and flow of air to the mold.

3. Pressure Regulator: The pressure regulator is responsible for controlling the amount of air that is released from the accumulator into the mold. It is connected to the accumulator and the mold and is set to maintain a specific pressure level during the blow molding process.

The pressure system works in the following steps:

1. The air compressor compresses air and stores it in the accumulator tank.

2. The accumulator tank releases the compressed air into the pressure regulator.

3. The pressure regulator controls the flow of air into the mold, maintaining a specific pressure level.

4. The mold is closed and the parison is placed inside.

5. The mold is then clamped shut and the parison is inflated with the compressed air, taking the shape of the mold.

6. Once the plastic has cooled and solidified, the mold is opened and the finished product is ejected.

7. The pressure system continues to supply compressed air to the mold until the desired product is formed.

The pressure system is crucial in ensuring the quality and consistency of the blow molded products. It must be carefully monitored and maintained to ensure proper pressure levels are maintained throughout the process.

8.Is there a limit to the size range of continuos extrusion blow molding?

We continue to invest in research and development and continue to launch innovative products.

Yes, there is a limit to the size range of blow molding machines. The size range of blow molding machines is typically determined by the maximum volume of the mold cavity and the maximum clamping force of the machine. The maximum volume of the mold cavity can range from a few milliliters to several liters, while the maximum clamping force can range from a few tons to several hundred tons.

Therefore, the size range of blow molding machines can vary greatly depending on the specific machine and its capabilities. Generally, blow molding machines are used to produce plastic products ranging from small bottles and containers to larger items such as automotive parts and large industrial containers.

Tags: blow molding machin , blow molding machine for plastic product