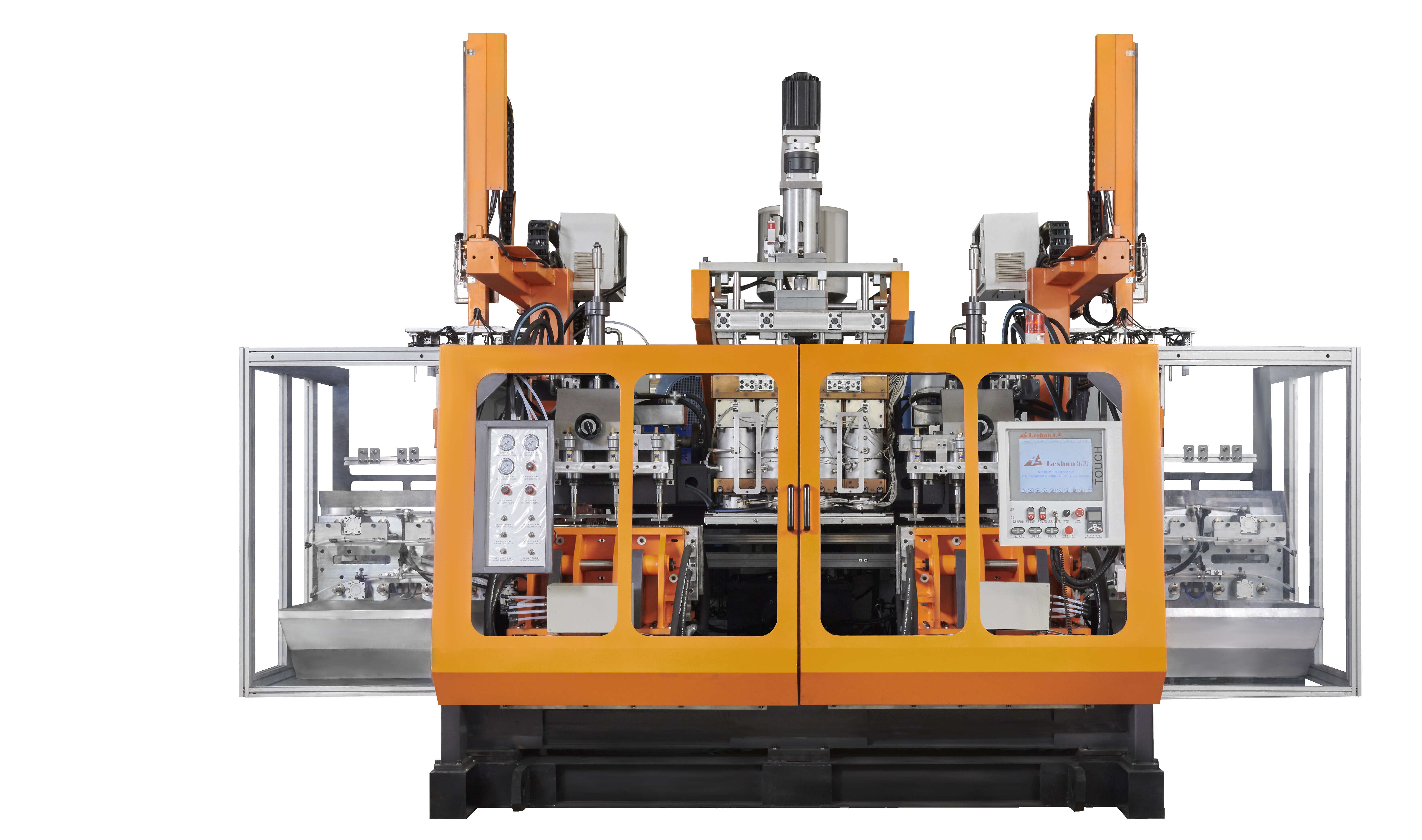

Cheap Extrusion Blow Moulding Machine

Cheap Extrusion Blow Moulding Machine

Leshan Intelligent Equipment Company is a well-known firm of expert China blow molding machine supplier that provides you with the finest solution when it comes to plastic production. With the guaranteed optimal production of plastic bottles, the top-tier China bottle blow molding machine manufacturer We introduce our customers to the latest machinery technology so that they can improve the productivity in their industries and provide high-quality products to their customers.

Our main products include Hydraulic Blow Molding Machine, All-Electric PET Blow Molding Machine,High-precision Mould,Blowing Mould & Injection Mould,Cleaning bottle blow molding machine,Daily chemistry bottle blow molding machine,Auxiliary machine,Food bottle blow molding machine,Milk bottle blow molding machine,Extrusion Die Head,PET Machine,athlon series hydraulic machine,Engine oil bottle blow molding machine,Irregular shape product blow molding machine,etc.Both various regions sales team and service network are dedicating to supply the impeccable pre-sales and after-sales service. We also offer the fastest reaction and solution to clients'questions and requirements.

| Parameter | Information |

|---|---|

| Product Name | cheap extrusion blow moulding machine |

| Brand Name | Leshan |

| Place of Origin | Foshan,China |

| Plastic Processed | PA,PVC,PC,HDPE,EVA,PE,Polystyrene...etc |

| Air Pressure(MPa) | 0.8 MPa |

| Color | Customized Color |

| Delivery Time | 45 days |

| Port | ShunDe/GuangZhou/ShenZhen China |

| Export region | Africa,Europe,Oceania |

| Export Country | Russia, Australia, Poland,Kazakhstan,Cocos (Keeling) Islands,Argentina,Bhutan...etc |

| Application | Bottle |

| OEM/ODM | Acceptatble |

| Core Components | Pressure vessel,PLC,Gear,Pump,Engine...etc |

| Voltage | 380V |

| Service | Free spare parts... |

| MOQ | 1 set |

| Certification | ISO9001,CE... |

| Supply Ability | 500 Set/Sets per Month |

| Weight (T) | 5-18(According to specific model) |

| Packaging Details | Standard exporting machine packing with plastic film |

| Lead time (days) | 70 (To be negotiated) |

Please note: The above table data is for reference only. For specific information, please contact us.

cheap extrusion blow moulding machine also has the characteristics of high efficiency, energy saving and environmental protection. During the manufacturing process, the blow molding machine can reduce energy consumption and the generation of emissions by recycling waste gas and waste liquid, thereby achieving the purpose of energy saving and emission reduction.

In addition, the blow molding machine can also use multi-layer molds to provide products with composite properties and increase the added value of the product.

cheap extrusion blow moulding machine---FAQs Guide

2.How do cheap extrusion blow moulding machine manufacturers control variables like temperature, pressure, and blow time in the blow molding process to ensure consistent product quality?

3.What is the noise level of the cheap extrusion blow moulding machine?

4.How to choose a suitable cheap extrusion blow moulding machine supplier?

5.How to prevent air leakage in cheap extrusion blow moulding machine?

6.What types of blow molding machines are there?

7.What are the safety standards for cheap extrusion blow moulding machine?

8.What are the general raw materials for cheap extrusion blow moulding machine?

9.Why does the blow molding machine make so much noise when it exhausts?

10.Can you supply the on-site installation,commissioning,training service for cheap extrusion blow moulding machine?

11.What are the main components of a cheap extrusion blow moulding machine?

12.About cheap extrusion blow moulding machine,Do you provide samples? ls it free or extra?

1.What's the difference between a double-working blow molding machine and a simplex blow molding machine?

The output demand of the same kind of product is big, choose double station blow molding machine.Single product demand is small, choose simplex blow molding machine.

2.How do cheap extrusion blow moulding machine manufacturers control variables like temperature, pressure, and blow time in the blow molding process to ensure consistent product quality?

We pay attention to the transformation of intellectual property protection and innovation achievements. Your OEM or ODM order design we have a complete confidentiality system.

1. Temperature Control: Blow molding machines have heating elements that are used to heat the plastic material to a specific temperature before it is blown into the mold. The temperature is controlled by sensors and thermostats that monitor and adjust the temperature as needed. This ensures that the plastic material is at the optimal temperature for the blow molding process, which helps to produce consistent product quality.

2. Pressure Control: The pressure in the blow molding process is controlled by the air pressure in the mold. The blow molding machine has a pressure regulator that controls the amount of air that is blown into the mold. This pressure is monitored and adjusted to ensure that it is consistent throughout the molding process. This helps to ensure that the plastic material is evenly distributed and that the final product has consistent wall thickness.

3. Blow Time Control: The blow time refers to the amount of time that the air is blown into the mold to inflate the plastic material. This is a critical variable in the blow molding process as it determines the final shape and size of the product. Blow molding machines have timers that control the duration of the blow time, and these can be adjusted to ensure consistent product quality.

4. Process Monitoring: Blow molding machine manufacturers also use advanced process monitoring systems to track and control the variables in the blow molding process. These systems use sensors and software to monitor and adjust the temperature, pressure, and blow time in real-time. This helps to ensure that any variations in these variables are immediately detected and corrected, resulting in consistent product quality.

5. Quality Control: In addition to controlling the variables during the blow molding process, manufacturers also have quality control measures in place to ensure consistent product quality. This includes regular testing and inspection of the final products to check for any defects or variations. Any issues are identified and addressed to maintain the desired level of product quality.

3.What is the noise level of the cheap extrusion blow moulding machine?

cheap extrusion blow moulding machine is not a product only, but also can help you comes to money-making.

The noise level of a blow molding machine can vary depending on the specific machine and its operating conditions. However, on average, blow molding machines can produce noise levels between 80-100 decibels (dB). This is considered to be a high level of noise and can potentially cause hearing damage if proper precautions are not taken. It is important for operators and workers to wear appropriate hearing protection when working with blow molding machines.

4.How to choose a suitable cheap extrusion blow moulding machine supplier?

We adhere to the principle of quality first and have a complete production quality management system and quality inspection process.

1. Research and compare different suppliers: Start by researching and comparing different blow molding machine suppliers. Look for their experience, reputation, and customer reviews to get an idea of their reliability and quality of products.

2. Consider the type of blow molding machine you need: There are different types of blow molding machines available, such as extrusion blow molding, injection blow molding, and stretch blow molding. Choose a supplier who specializes in the type of machine you need.

3. Quality of machines: The quality of the blow molding machine is crucial for its performance and durability. Look for suppliers who use high-quality materials and have a strict quality control process in place.

4. Customization options: If you have specific requirements for your blow molding machine, look for a supplier who offers customization options. This will ensure that the machine is tailored to your needs and can meet your production requirements.

5. After-sales support: A good supplier should offer after-sales support, including installation, training, and maintenance services. This will ensure that your machine runs smoothly and any issues are resolved promptly.

6. Price and payment terms: Compare the prices of different suppliers and choose one that offers competitive pricing without compromising on quality. Also, consider the payment terms and choose a supplier who offers flexible payment options.

7. Technical support: Blow molding machines are complex equipment, and it is essential to have technical support in case of any issues. Choose a supplier who offers technical support and has a team of experienced technicians.

8. Delivery time: If you have a tight production schedule, it is crucial to choose a supplier who can deliver the machine within the specified time frame. Inquire about their delivery time and make sure it aligns with your production schedule.

9. Warranty and service contracts: A good supplier should offer a warranty for their machines and also provide service contracts for regular maintenance. This will ensure that your machine remains in good condition and has a longer lifespan.

10. Communication and responsiveness: Choose a supplier who has good communication and is responsive to your queries and concerns. This will ensure a smooth and hassle-free buying experience.

5.How to prevent air leakage in cheap extrusion blow moulding machine?

We should perform well in market competition, and the prices of cheap extrusion blow moulding machine products have a great competitive advantage.

1. Regular Maintenance: Regular maintenance of the blow molding machine is essential to prevent air leakage. This includes checking and replacing worn out seals, gaskets, and other components that may contribute to air leakage.

2. Proper Lubrication: Lubrication of moving parts is important to ensure smooth operation of the machine and prevent air leakage. Make sure to use the recommended lubricants and follow the manufacturer's instructions for lubrication intervals.

3. Check Air Hoses and Fittings: Inspect the air hoses and fittings for any cracks, tears, or loose connections. Replace any damaged parts immediately to prevent air leakage.

4. Use High-Quality Components: Using high-quality components, such as valves, seals, and gaskets, can help prevent air leakage in the blow molding machine. These components are designed to withstand high pressures and are less likely to fail.

5. Adjust Air Pressure: Make sure to adjust the air pressure according to the manufacturer's recommendations. Too much or too little air pressure can cause air leakage in the machine.

6. Properly Align Parts: Misaligned parts can cause air leakage in the blow molding machine. Make sure all parts are properly aligned and tightened to prevent air from escaping.

7. Regularly Inspect the Machine: Regularly inspect the machine for any signs of air leakage, such as hissing sounds or drops in air pressure. If any issues are found, address them immediately to prevent further air leakage.

8. Train Operators: Properly trained operators can help prevent air leakage by operating the machine correctly and identifying any potential issues before they become major problems.

9. Use Air Leak Detection Systems: Consider using air leak detection systems to identify and locate any air leaks in the machine. This can help prevent air leakage and improve the overall efficiency of the machine.

10. Replace Worn Out Parts: Over time, parts of the blow molding machine may wear out and contribute to air leakage. It is important to regularly replace these parts to maintain the integrity of the machine and prevent air leakage.

6.What types of blow molding machines are there?

We should have a stable supply chain and logistics capabilities, and provide customers with high -quality, low -priced cheap extrusion blow moulding machine products.

1. Extrusion blow molding machine: This type of machine uses a continuous extrusion process to produce hollow plastic products, such as bottles, containers, and tanks.

2. Injection blow molding machine: This machine combines the processes of injection molding and blow molding to produce small, complex, and precise plastic products, such as medical devices and electronic components.

3. Stretch blow molding machine: This machine uses a two-stage process to produce high-quality, lightweight bottles and containers from PET (polyethylene terephthalate) material.

4. Reheat stretch blow molding machine: This type of machine is similar to the stretch blow molding machine, but it uses preforms (partially formed bottles) instead of raw material to produce bottles and containers.

5. Rotational blow molding machine: This machine uses a rotating mold to produce large, hollow plastic products, such as tanks, drums, and toys.

6. Shuttle blow molding machine: This machine has a shuttle system that moves the mold back and forth, allowing for the production of larger and more complex products.

7. Injection stretch blow molding machine: This machine combines the processes of injection molding and stretch blow molding to produce high-quality, lightweight bottles and containers from PET material.

8. Accumulator blow molding machine: This machine uses an accumulator to store molten plastic, which is then used to produce large and complex products, such as automotive parts and industrial containers.

9. Continuous extrusion blow molding machine: This machine uses a continuous extrusion process to produce long, tubular plastic products, such as pipes and tubes.

10. Co-extrusion blow molding machine: This machine uses multiple extruders to produce products with multiple layers, allowing for the production of complex and multi-functional products.

7.What are the safety standards for cheap extrusion blow moulding machine?

We are a new cheap extrusion blow moulding machine manufacturer.

1. Electrical Safety: Blow molding machines should comply with all relevant electrical safety standards, such as the National Electrical Code (NEC) and the International Electrotechnical Commission (IEC) standards.

2. Machine Guarding: All moving parts of the machine should be guarded to prevent accidental contact and injuries. The guards should be securely fixed and not easily removable.

3. Emergency Stop: The machine should have an easily accessible emergency stop button that can quickly shut down the machine in case of an emergency.

4. Lockout/Tagout: The machine should have a lockout/tagout system in place to prevent accidental start-up during maintenance or repair.

5. Pressure Relief: Blow molding machines use high-pressure air to mold plastic, so they should have a pressure relief system in place to prevent over-pressurization and potential explosions.

6. Material Handling: The machine should have a safe and efficient material handling system to prevent injuries and accidents during the loading and unloading of materials.

7. Noise Control: Blow molding machines can produce high levels of noise, so they should have noise control measures in place to protect workers' hearing.

8. Fire Safety: The machine should have fire safety measures in place, such as fire extinguishers and fire alarms, to prevent and control fires.

9. Operator Training: All operators should receive proper training on how to operate the machine safely and be aware of potential hazards.

10. Regular Maintenance: The machine should undergo regular maintenance and inspections to ensure it is in good working condition and meets all safety standards.

8.What are the general raw materials for cheap extrusion blow moulding machine?

We pay attention to employee development and benefits, and provide a good working environment in order to improve the efficiency of employees and improve the quality management of cheap extrusion blow moulding machine products.

1. Plastic Resin: The most common raw material used in blow molding machines is plastic resin, which is melted and formed into a hollow tube to create the desired shape.

2. Colorants: Colorants are added to the plastic resin to give the final product its desired color.

3. Additives: Additives such as UV stabilizers, antioxidants, and flame retardants may be added to the plastic resin to improve the properties of the final product.

4. Compressed Air: Compressed air is used to inflate the plastic tube and shape it against the mold.

5. Mold Release Agents: Mold release agents are used to prevent the plastic from sticking to the mold during the molding process.

6. Lubricants: Lubricants are used to reduce friction between the plastic and the mold, making it easier to remove the final product.

7. Cooling Water: Cooling water is used to cool the plastic and solidify it into the desired shape.

8. Mold Inserts: Mold inserts are used to create specific features or details on the final product.

9. Labels and Packaging Materials: Labels and packaging materials may be added to the final product after it has been molded.

10. Recycled Materials: Some blow molding machines may also use recycled plastic materials as a raw material, reducing waste and promoting sustainability.

9.Why does the blow molding machine make so much noise when it exhausts?

The exhaust valve is blocked or the exhaust valve and exhaust pipe are too small.

10.Can you supply the on-site installation,commissioning,training service for cheap extrusion blow moulding machine?

Yes. We can. But this service cost will be extra cost based on which location.

11.What are the main components of a cheap extrusion blow moulding machine?

We have rich industry experience and professional knowledge, and have strong competitiveness in the market.

1. Extruder: This is the main component of a blow molding machine, which melts and forms the plastic material into a parison (hollow tube).

2. Die Head: The die head is responsible for shaping the parison into the desired shape and size.

3. Clamping Unit: The clamping unit holds the mold in place and provides the necessary pressure for the blowing process.

4. Blow Pin: The blow pin is used to inflate the parison and shape it against the mold.

5. Cooling System: The cooling system helps to cool down the plastic material and solidify it into the desired shape.

6. Control System: The control system is responsible for controlling and monitoring the various parameters of the blow molding process, such as temperature, pressure, and speed.

7. Mold: The mold is the cavity into which the plastic material is blown and takes the shape of the final product.

8. Ejector: The ejector removes the finished product from the mold after the blowing process is complete.

9. Hydraulic System: The hydraulic system provides the necessary power and pressure for the various movements of the machine.

10. Electrical System: The electrical system controls the various motors and sensors of the machine.

11. Air Compressor: The air compressor supplies the compressed air needed for the blowing process.

12. Chiller: The chiller is used to cool down the extruder and other components of the machine to maintain the required temperature.

13. Conveyor System: The conveyor system moves the finished products out of the machine for further processing or packaging.

12.About cheap extrusion blow moulding machine,Do you provide samples? ls it free or extra?

Yes,we could offer you the sample.But it's not free.You need to pay for the sample and the cost of freight.

Tags: China extrusion blowing machine, China 100l blow molding machine