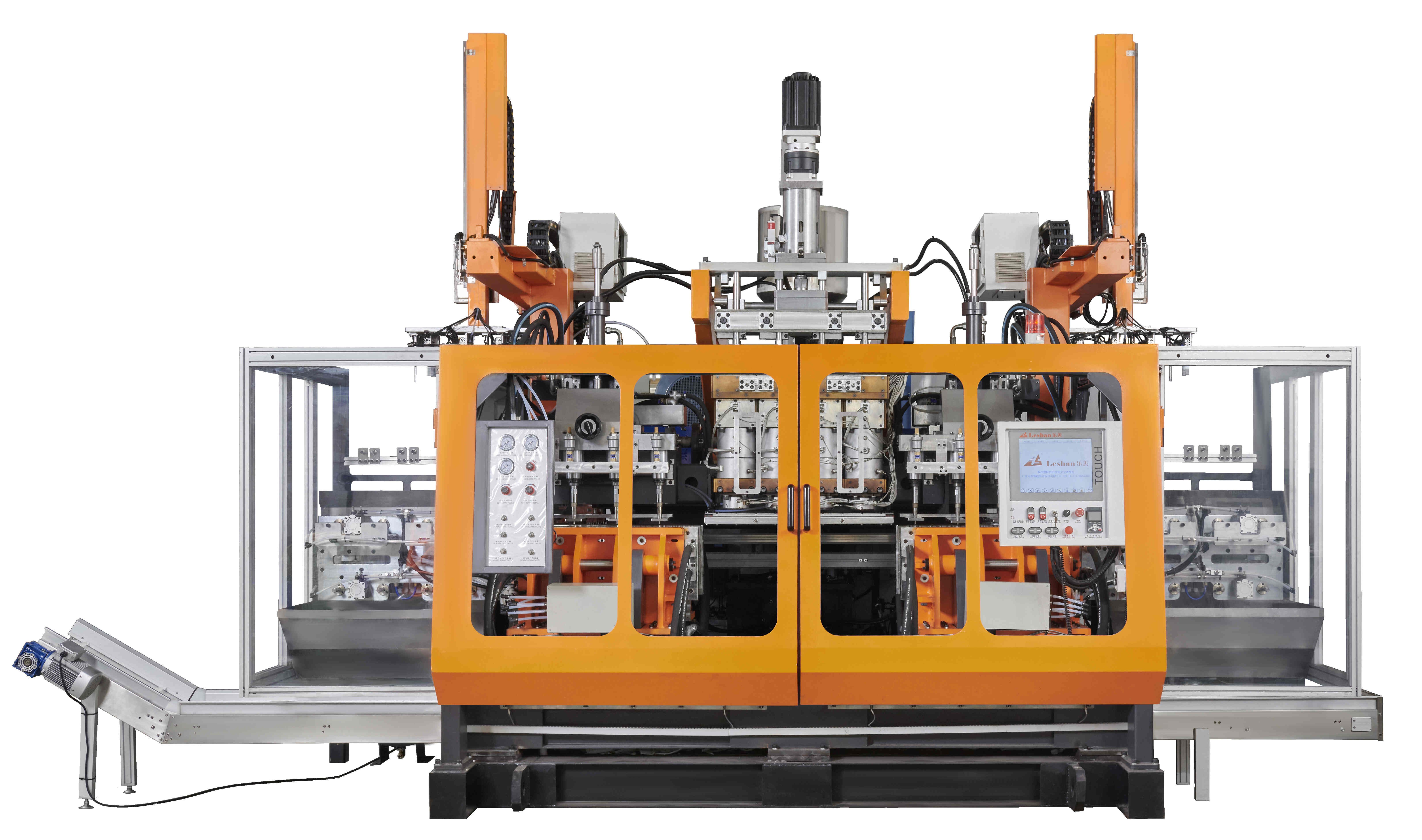

Automatic Plastic Blow Molding Machine

Automatic Plastic Blow Molding Machine

Leshan Intelligent Equipment Corp.,Ltd is a well-known firm of expert China blow molding machine supplier that provides you with the finest solution when it comes to plastic production. With the guaranteed optimal production of plastic bottles, the top-tier China bottle blow molding machine manufacturer We introduce our customers to the latest machinery technology so that they can improve the productivity in their industries and provide high-quality products to their customers.

Our main products include Hydraulic Blow Molding Machine, All-Electric PET Blow Molding Machine,High-precision Mould,Cleaning bottle blow molding machine,Blowing Mould & Injection Mould,Irregular shape product blow molding machine,Auxiliary machine,PET Machine,Chemical barrel blow molding machine,Engine oil bottle blow molding machine,Milk bottle blow molding machine,athlon series hydraulic machine,etc.Both various regions sales team and service network are dedicating to supply the impeccable pre-sales and after-sales service. We also offer the fastest reaction and solution to clients'questions and requirements.

| Parameter | Information |

|---|---|

| Product Name | automatic plastic blow molding machine |

| Brand Name | Leshan |

| Place of Origin | Foshan,China |

| Plastic Processed | ABS,PC,Polystyrene,HDPE,PVC,PE...etc |

| Air Pressure(MPa) | 0.8 MPa |

| Color | Customized Color |

| Delivery Time | 45 days |

| Port | ShunDe/GuangZhou/ShenZhen China |

| Export region | America,Oceania,Africa |

| Export Country | Russia, Australia, Poland,Tuvalu,Ukraine,Sao Tome and Principe,Reunion...etc |

| Application | Bottle |

| OEM/ODM | Support |

| Core Components | Pressure vessel,Gear,Motor,Gearbox,Engine...etc |

| Voltage | 380V |

| Service | Free spare parts... |

| MOQ | 1 set |

| Certification | ISO9001,CE... |

| Supply Ability | 500 Set/Sets per Month |

| Weight (T) | 5-18(According to specific model) |

| Packaging Details | Standard exporting machine packing with plastic film |

| Lead time (days) | 70 (To be negotiated) |

Please note: The above table data is for reference only. For specific information, please contact us.

As a commonly used plastic processing machine, automatic plastic blow molding machine has the characteristics of powerful functions and easy operation. It can complete the heating, plasticizing, blowing, cooling and other processes of plastic in one mold feeding and molding process, thereby making the product lightweight, durable, transparent and other advantages.

At the same time, the blow molding machine also has high production efficiency, can continuously produce large quantities of products, and is suitable for manufacturing plastic containers of various specifications and shapes.

automatic plastic blow molding machine---FAQs Guide

2.What's the difference between a double-working blow molding machine and a simplex blow molding machine?

3.Which industries can apply automatic plastic blow molding machine?

4.What is the cost composition of automatic plastic blow molding machine?

5.What is the difference between traditional automatic plastic blow molding machine and fully computer-controlled blow molding machines?

6.How to prevent air leakage in automatic plastic blow molding machine?

7.How to design and customize automatic plastic blow molding machine?

8.How long is the production cycle of Leshan blow molding machine? What is the lead time?

1.Where is your factory located? How can I visit there?

Our factory is located in Shunde, Foshan City, Guangdong Province, China. All our clients, from home or abroad, are warmly welcome to visit us!

2.What's the difference between a double-working blow molding machine and a simplex blow molding machine?

The output demand of the same kind of product is big, choose double station blow molding machine.Single product demand is small, choose simplex blow molding machine.

3.Which industries can apply automatic plastic blow molding machine?

Being one of the top automatic plastic blow molding machine manufacturers in China, We attach great importance to this detail.

1. Packaging industry: Blow molding machines are commonly used in the packaging industry to produce plastic bottles, containers, and other packaging materials.

2. Automotive industry: Blow molding machines are used to produce various automotive components such as fuel tanks, air ducts, and bumpers.

3. Consumer goods industry: Many consumer goods such as toys, household items, and personal care products are made using blow molding machines.

4. Medical industry: Blow molding machines are used to produce medical devices and equipment such as IV bags, syringes, and medical tubing.

5. Construction industry: Blow molding machines are used to produce large plastic tanks, pipes, and other construction materials.

6. Agriculture industry: Agricultural products such as irrigation pipes, water tanks, and seedling trays are produced using blow molding machines.

7. Electronics industry: Blow molding machines are used to produce plastic casings and components for electronic devices.

8. Furniture industry: Blow molding machines are used to produce plastic furniture components such as chairs, tables, and storage units.

9. Sports and recreation industry: Many sports and recreation products such as kayaks, surfboards, and playground equipment are made using blow molding machines.

10. Aerospace industry: Blow molding machines are used to produce lightweight and durable components for aircraft and spacecraft.

4.What is the cost composition of automatic plastic blow molding machine?

We focus on providing high automatic plastic blow molding machine quality products and services.

The cost composition of blow molding machines can vary depending on the type and size of the machine, as well as the manufacturer and country of origin. However, the general cost composition can be broken down into the following components:

1. Machine base: This includes the main frame, base plate, and other structural components of the machine. It typically accounts for 20-30% of the total cost.

2. Extruder: The extruder is the heart of the blow molding machine and is responsible for melting and shaping the plastic material. It can account for 30-40% of the total cost.

3. Molds: Molds are used to shape the plastic material into the desired product. The cost of molds can vary greatly depending on the complexity and size of the product being produced. It can account for 20-30% of the total cost.

4. Control system: The control system includes the electrical and electronic components that control the operation of the machine. It can account for 10-15% of the total cost.

5. Hydraulic system: The hydraulic system is responsible for providing the necessary pressure and power to operate the machine. It can account for 5-10% of the total cost.

6. Other components: Other components such as motors, pumps, valves, and sensors can also contribute to the overall cost of the machine.

In addition to these components, the cost of blow molding machines may also include expenses such as labor, transportation, and installation. It is important to note that the cost composition may vary depending on the specific features and capabilities of the machine.

5.What is the difference between traditional automatic plastic blow molding machine and fully computer-controlled blow molding machines?

We have the leading technology and innovation capabilities, and attach importance to employee training and development, and provide promotion opportunities.

Traditional blow molding machines are operated manually by a person, while fully computer-controlled blow molding machines are operated by a computer program. This means that traditional blow molding machines require more human labor and supervision, while fully computer-controlled machines can run automatically with minimal human intervention.

Additionally, traditional blow molding machines may have limited capabilities and may only be able to produce simple shapes, while fully computer-controlled machines can produce more complex and precise shapes. This is because the computer program can control the machine's movements and parameters with greater accuracy and consistency.

Furthermore, fully computer-controlled blow molding machines often have advanced features such as real-time monitoring, data collection, and automatic adjustments, which can improve efficiency and quality control.

Overall, the main difference between traditional blow molding machines and fully computer-controlled machines is the level of automation and precision in the production process.

6.How to prevent air leakage in automatic plastic blow molding machine?

We should perform well in market competition, and the prices of automatic plastic blow molding machine products have a great competitive advantage.

1. Regular Maintenance: Regular maintenance of the blow molding machine is essential to prevent air leakage. This includes checking and replacing worn out seals, gaskets, and other components that may contribute to air leakage.

2. Proper Lubrication: Lubrication of moving parts is important to ensure smooth operation of the machine and prevent air leakage. Make sure to use the recommended lubricants and follow the manufacturer's instructions for lubrication intervals.

3. Check Air Hoses and Fittings: Inspect the air hoses and fittings for any cracks, tears, or loose connections. Replace any damaged parts immediately to prevent air leakage.

4. Use High-Quality Components: Using high-quality components, such as valves, seals, and gaskets, can help prevent air leakage in the blow molding machine. These components are designed to withstand high pressures and are less likely to fail.

5. Adjust Air Pressure: Make sure to adjust the air pressure according to the manufacturer's recommendations. Too much or too little air pressure can cause air leakage in the machine.

6. Properly Align Parts: Misaligned parts can cause air leakage in the blow molding machine. Make sure all parts are properly aligned and tightened to prevent air from escaping.

7. Regularly Inspect the Machine: Regularly inspect the machine for any signs of air leakage, such as hissing sounds or drops in air pressure. If any issues are found, address them immediately to prevent further air leakage.

8. Train Operators: Properly trained operators can help prevent air leakage by operating the machine correctly and identifying any potential issues before they become major problems.

9. Use Air Leak Detection Systems: Consider using air leak detection systems to identify and locate any air leaks in the machine. This can help prevent air leakage and improve the overall efficiency of the machine.

10. Replace Worn Out Parts: Over time, parts of the blow molding machine may wear out and contribute to air leakage. It is important to regularly replace these parts to maintain the integrity of the machine and prevent air leakage.

7.How to design and customize automatic plastic blow molding machine?

We actively participate in the automatic plastic blow molding machine industry associations and organization activities. The corporate social responsibility performed well, and the focus of brand building and promotion

Designing and customizing blow molding machines involves several steps and considerations. Here are some steps to follow:

1. Identify the type of blow molding machine needed: There are different types of blow molding machines, such as extrusion blow molding, injection blow molding, and stretch blow molding. Each type has its own unique features and capabilities, so it is important to determine the specific type of machine needed for the desired application.

2. Determine the production requirements: The production requirements, such as the desired output, bottle size and shape, and material type, will help determine the specifications and features of the machine.

3. Select the appropriate components: The components of a blow molding machine include the extruder, mold, clamping system, and control system. Each component should be carefully selected based on the production requirements and the type of machine.

4. Consider the material and design of the mold: The mold is a crucial component of a blow molding machine as it determines the shape and size of the final product. The material and design of the mold should be chosen based on the type of material being used and the desired product specifications.

5. Customize the control system: The control system is responsible for the operation and monitoring of the machine. It should be customized to meet the specific production requirements and to ensure efficient and safe operation.

6. Incorporate safety features: Safety should be a top priority when designing and customizing blow molding machines. Safety features such as emergency stop buttons, safety guards, and sensors should be incorporated into the design to prevent accidents and ensure the safety of operators.

7. Test and optimize the machine: Once the machine is designed and assembled, it should be thoroughly tested to ensure it meets the production requirements and operates efficiently. Any necessary adjustments or optimizations should be made before the machine is put into full production.

8. Provide training and support: It is important to provide training and support to operators and maintenance personnel to ensure they are familiar with the machine and can operate and maintain it properly.

In addition to these steps, it is important to work closely with a reputable manufacturer or supplier who has experience in designing and customizing blow molding machines. They can provide valuable insights and expertise to help create a machine that meets your specific needs and requirements.

8.How long is the production cycle of Leshan blow molding machine? What is the lead time?

Production cycle 40-45 days; Delivery time: 60 days.

Tags: multiple layers blow molding machine,extrusion blow molding machine parts,auto pet blow mold machine,three die head 50l blow molding machine