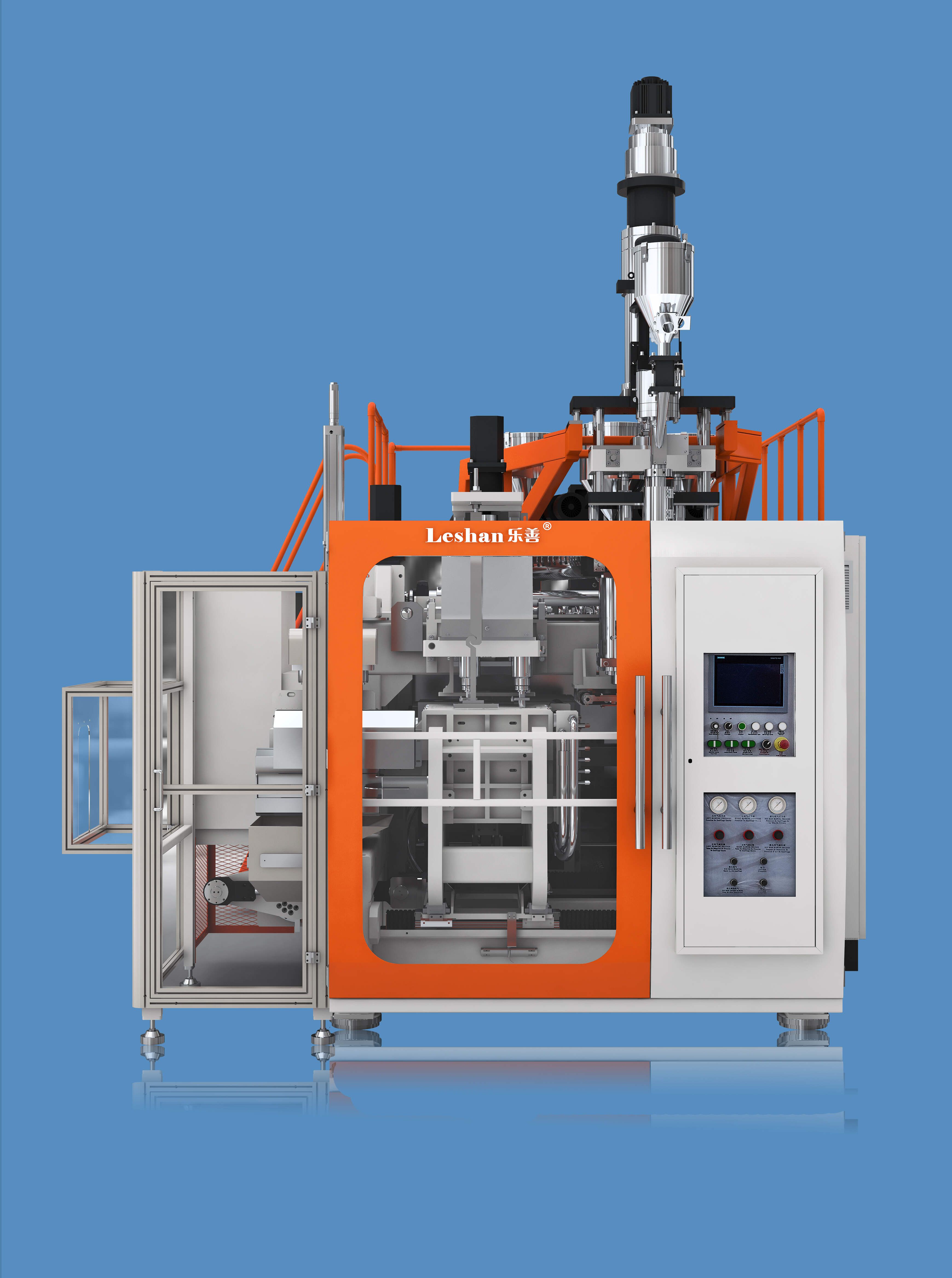

Automatic Pet Blow Mold Machine

Automatic Pet Blow Mold Machine

Leshan Intelligent Equipment Company was established in 1995 and is located in Foshan, Guangdong. Our business scope includes exporting Hydraulic Blow Molding Machine, All-Electric PET Blow Molding Machine,High-precision Mould,Engine oil bottle blow molding machine,Daily chemistry bottle blow molding machine,multi-layer coextrusion blow molding machine,Extrusion Die Head,athlon series hydraulic machine,Auxiliary machine,Food bottle blow molding machine,Chemical barrel blow molding machine,Milk bottle blow molding machine and other equipment. We are also armed with comprehensive strength such as strong R&D power,production marketing,technical support,etc... Through years of creation , Leshan has been transformed the patent technology into application.

We also use International standards and the ISO9001:2012 quality management system in producing. Currently, our company's products are exported to over 50 countries and regions worldwide. Including: Russia, Australia, Poland, Saudi Arabia, Bengal, Vietnam , etc...

| Parameter | Information |

|---|---|

| Product Name | automatic pet blow mold machine |

| Brand Name | Leshan |

| Place of Origin | Foshan,Guangdong |

| Plastic Processed | PC,PP,ABS,PVC,PA,Polystyrene...etc |

| Air Pressure(MPa) | 0.8 MPa |

| Color | Customized Color |

| Delivery Time | 45 days |

| Port | ShunDe/GuangZhou/ShenZhen China |

| Export region | Africa,Europe,Oceania |

| Export Country | Russia, Australia, Poland,Lithuania,Peru,Russia,Gibraltar...etc |

| Application | Bottle |

| OEM/ODM | Support |

| Core Components | PLC,Bearing,Pump,Pressure vessel,Gearbox,Gear...etc |

| Voltage | 380V |

| Service | Video technical support... |

| MOQ | 1 set |

| Certification | ISO9001,CE... |

| Supply Ability | 500 Set/Sets per Month |

| Weight (T) | 5-18(According to specific model) |

| Packaging Details | Standard exporting machine packing with plastic film |

| Lead time (days) | 70 (To be negotiated) |

Please note: The above table data is for reference only. For specific information, please contact us.

automatic pet blow mold machine is an indispensable and important equipment in modern plastic manufacturing industry, and its characteristics are constantly being improved and developed. Future blow molding machines will be more intelligent, energy-saving and environmentally friendly, and have more additional functions to meet changing market demands. At the same time, with the introduction of new degradable plastics, blow molding machines will also adapt to the processing of new materials, promoting the development of the plastic products industry in a more environmentally friendly and sustainable direction.

automatic pet blow mold machine---FAQs Guide

2.How to maintain the stability of automatic pet blow mold machine?

3.What is the operating cost of a automatic pet blow mold machine?

4.How to improve the production capacity and speed of automatic pet blow mold machine?

5.Where is your factory located? How can I visit there?

6.How to optimize the efficiency of plastic blow molding machine?

7.What are the safety standards for automatic pet blow mold machine?

8.What is the working principle of a blow molding machine?

9.What is the noise level of the automatic pet blow mold machine?

10.How long is the production cycle of Leshan blow molding machine? What is the lead time?

11.What's the difference between a double-working blow molding machine and a simplex blow molding machine?

12.Which industries can apply automatic pet blow mold machine?

1.What materials can be used to manufacture automatic pet blow mold machine?

We should enjoy a good reputation in the industry, and we can increase the added value of the products of cooperative customers through technological innovation.

1. Steel: The main structural material used in blow molding machines is steel, which provides strength and durability to the machine.

2. Aluminum: Some parts of the machine, such as the extruder, may be made from aluminum due to its lightweight and corrosion-resistant properties.

3. Plastic: The molds used in blow molding machines are typically made from plastic, such as high-density polyethylene (HDPE) or polypropylene (PP).

4. Rubber: Rubber is used for seals and gaskets in the machine to prevent leakage and ensure airtightness.

5. Brass: Brass is used for valves and fittings in the machine due to its corrosion resistance and ability to withstand high temperatures.

6. Copper: Copper is used for electrical components and wiring in the machine due to its good conductivity.

7. Stainless steel: Some parts of the machine, such as the heating elements, may be made from stainless steel due to its resistance to corrosion and high temperatures.

8. Glass: Glass is used for the viewing window on the machine, allowing operators to monitor the production process.

9. Ceramic: Ceramic is used for heating elements and insulation in the machine due to its ability to withstand high temperatures.

10. Composites: Some parts of the machine, such as the control panel, may be made from composite materials, which offer a combination of strength, durability, and lightweight properties.

2.How to maintain the stability of automatic pet blow mold machine?

We enjoy high authority and influence in the industry and continue to innovate products and service models.

1. Regular Maintenance: Regular maintenance is crucial for the stability of blow molding machines. This includes cleaning, lubricating, and inspecting the machine on a regular basis. Any worn or damaged parts should be replaced immediately to prevent further damage.

2. Proper Training: Ensure that all operators are properly trained on how to operate the blow molding machine. This will help prevent any accidents or damage to the machine due to operator error.

3. Use Quality Materials: The quality of the materials used in the blow molding process can affect the stability of the machine. Using high-quality materials will reduce the risk of machine breakdowns and improve the overall performance.

4. Monitor Machine Performance: Keep a close eye on the performance of the machine. This includes monitoring the temperature, pressure, and speed of the machine. Any abnormalities should be addressed immediately to prevent further damage.

5. Regular Inspections: Regularly inspect the machine for any signs of wear and tear. This will help identify any potential issues before they become major problems.

6. Follow Manufacturer's Guidelines: Follow the manufacturer's guidelines for operating and maintaining the machine. This will ensure that the machine is being used correctly and will help prolong its lifespan.

7. Keep the Machine Clean: A clean machine is less likely to experience breakdowns. Regularly clean the machine and remove any debris or dust that may have accumulated.

8. Proper Storage: When the machine is not in use, it should be stored in a clean and dry environment. This will help prevent any damage caused by moisture or dust.

9. Address Issues Immediately: If any issues arise with the machine, address them immediately. Ignoring problems can lead to more serious issues and can affect the stability of the machine.

10. Schedule Professional Servicing: It is important to schedule professional servicing of the machine on a regular basis. This will help identify any potential issues and ensure that the machine is running at its optimal performance.

3.What is the operating cost of a automatic pet blow mold machine?

We attach importance to the innovation ability and team spirit of employees, have advanced R & D facilities and laboratories, and have a good quality management system.

The operating cost of a blow molding machine can vary depending on factors such as the size and type of machine, the materials being used, and the production volume. However, some common operating costs include:

1. Energy costs: Blow molding machines require a significant amount of energy to operate, including electricity for heating and cooling processes. The cost of energy can vary depending on the location and the efficiency of the machine.

2. Labor costs: The cost of labor includes the wages of operators and technicians who run the machine, as well as any maintenance or repair personnel.

3. Material costs: The cost of materials, such as plastic resins, can vary depending on the type and quality of the material being used.

4. Maintenance and repair costs: Regular maintenance and occasional repairs are necessary to keep the machine running smoothly, and these costs should be factored into the overall operating cost.

5. Overhead costs: This includes expenses such as rent, insurance, and administrative costs that are necessary for the operation of the machine.

Overall, the operating cost of a blow molding machine can range from a few hundred dollars per day for a small machine to thousands of dollars per day for a large, high-volume machine.

4.How to improve the production capacity and speed of automatic pet blow mold machine?

We pay attention to user experience and product quality, and provide the best product quality and lowest production cost for cooperative customers.

1. Regular Maintenance: Regular maintenance of the blow molding machine is essential to ensure its smooth functioning and prevent breakdowns. This includes cleaning, lubricating, and replacing worn-out parts.

2. Use High-Quality Materials: The quality of the materials used in the blow molding process can greatly affect the production capacity and speed. Using high-quality materials can result in faster production and better quality products.

3. Optimize the Design: The design of the blow molding machine can also impact its production capacity and speed. Optimizing the design to reduce the number of steps and improve the efficiency of the process can increase the production speed.

4. Increase Automation: Automation can greatly improve the production capacity and speed of blow molding machines. Automated processes can reduce the need for manual labor and increase the accuracy and speed of production.

5. Use Advanced Technology: Upgrading to newer and more advanced blow molding technology can significantly improve the production capacity and speed. This includes using computer-controlled systems, advanced sensors, and other technologies that can optimize the production process.

6. Train Operators: Properly trained operators can greatly improve the efficiency and speed of the blow molding process. They should be trained in operating the machine, troubleshooting common issues, and performing routine maintenance.

7. Implement Lean Manufacturing Principles: Implementing lean manufacturing principles can help identify and eliminate waste in the production process, resulting in increased efficiency and speed.

8. Increase the Number of Cavities: Increasing the number of cavities in the blow molding machine can significantly increase the production capacity. This allows for more products to be produced in a single cycle, reducing the overall production time.

9. Optimize Cooling Time: The cooling time of the products can greatly impact the production speed. Optimizing the cooling time by using advanced cooling methods can reduce the overall production time.

10. Monitor and Analyze Production Data: Regularly monitoring and analyzing production data can help identify bottlenecks and areas for improvement. This can help optimize the production process and increase the production capacity and speed.

5.Where is your factory located? How can I visit there?

Our factory is located in Shunde, Foshan City, Guangdong Province, China. All our clients, from home or abroad, are warmly welcome to visit us!

6.How to optimize the efficiency of plastic blow molding machine?

It can improve the blowing process, improve the cooling water transportation of the mold, improve the machine action time, improve the shape of the cup to make the material tube become even, thus reducing the molding cycle time of the product.

7.What are the safety standards for automatic pet blow mold machine?

We are a new automatic pet blow mold machine manufacturer.

1. Electrical Safety: Blow molding machines should comply with all relevant electrical safety standards, such as the National Electrical Code (NEC) and the International Electrotechnical Commission (IEC) standards.

2. Machine Guarding: All moving parts of the machine should be guarded to prevent accidental contact and injuries. The guards should be securely fixed and not easily removable.

3. Emergency Stop: The machine should have an easily accessible emergency stop button that can quickly shut down the machine in case of an emergency.

4. Lockout/Tagout: The machine should have a lockout/tagout system in place to prevent accidental start-up during maintenance or repair.

5. Pressure Relief: Blow molding machines use high-pressure air to mold plastic, so they should have a pressure relief system in place to prevent over-pressurization and potential explosions.

6. Material Handling: The machine should have a safe and efficient material handling system to prevent injuries and accidents during the loading and unloading of materials.

7. Noise Control: Blow molding machines can produce high levels of noise, so they should have noise control measures in place to protect workers' hearing.

8. Fire Safety: The machine should have fire safety measures in place, such as fire extinguishers and fire alarms, to prevent and control fires.

9. Operator Training: All operators should receive proper training on how to operate the machine safely and be aware of potential hazards.

10. Regular Maintenance: The machine should undergo regular maintenance and inspections to ensure it is in good working condition and meets all safety standards.

8.What is the working principle of a blow molding machine?

We focus on innovation and continuous improvement to maintain a competitive advantage.

The working principle of a blow molding machine involves the use of compressed air to inflate a molten plastic tube or parison inside a mold cavity. This creates a hollow shape that is then cooled and solidified to form a plastic product.

The process begins with the plastic material, usually in the form of pellets, being fed into a hopper and then melted in an extruder. The molten plastic is then forced into a long tube or parison, which is then clamped between two halves of a mold.

Next, a nozzle is inserted into the parison and compressed air is blown into it, causing the plastic to expand and take the shape of the mold cavity. The mold is cooled to solidify the plastic, and then the mold halves are separated, and the finished product is ejected.

The blow molding process can be either extrusion blow molding or injection blow molding, depending on the type of machine used. In extrusion blow molding, the parison is formed by extruding the molten plastic through a die, while in injection blow molding, the parison is formed by injecting the molten plastic into a mold cavity.

The working principle of a blow molding machine is based on the principles of thermodynamics and fluid mechanics, where the expansion of compressed air inside the parison creates pressure that forces the plastic to take the shape of the mold. This process allows for the production of hollow plastic products with complex shapes and sizes.

9.What is the noise level of the automatic pet blow mold machine?

automatic pet blow mold machine is not a product only, but also can help you comes to money-making.

The noise level of a blow molding machine can vary depending on the specific machine and its operating conditions. However, on average, blow molding machines can produce noise levels between 80-100 decibels (dB). This is considered to be a high level of noise and can potentially cause hearing damage if proper precautions are not taken. It is important for operators and workers to wear appropriate hearing protection when working with blow molding machines.

10.How long is the production cycle of Leshan blow molding machine? What is the lead time?

Production cycle 40-45 days; Delivery time: 60 days.

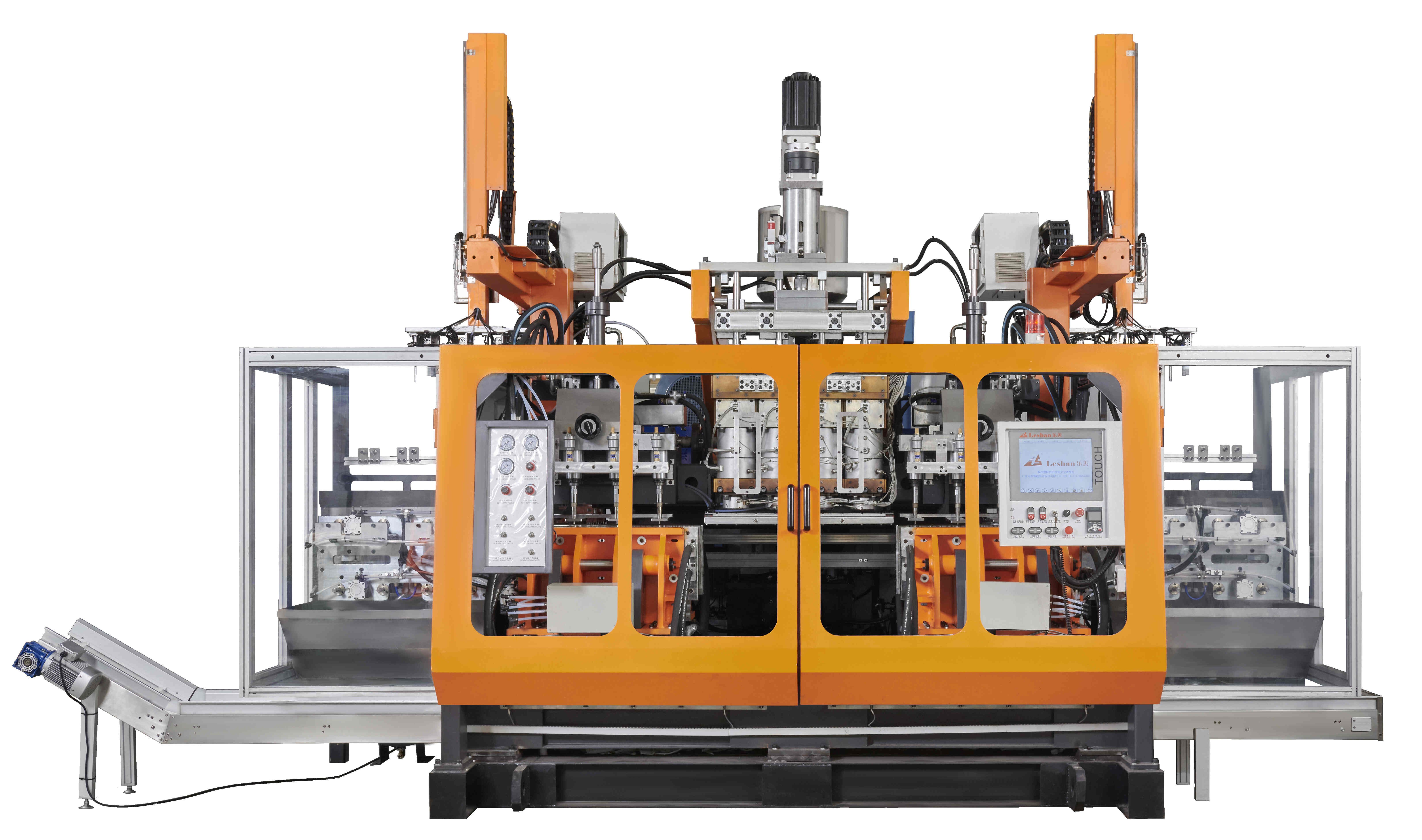

11.What's the difference between a double-working blow molding machine and a simplex blow molding machine?

The output demand of the same kind of product is big, choose double station blow molding machine.Single product demand is small, choose simplex blow molding machine.

12.Which industries can apply automatic pet blow mold machine?

Being one of the top automatic pet blow mold machine manufacturers in China, We attach great importance to this detail.

1. Packaging industry: Blow molding machines are commonly used in the packaging industry to produce plastic bottles, containers, and other packaging materials.

2. Automotive industry: Blow molding machines are used to produce various automotive components such as fuel tanks, air ducts, and bumpers.

3. Consumer goods industry: Many consumer goods such as toys, household items, and personal care products are made using blow molding machines.

4. Medical industry: Blow molding machines are used to produce medical devices and equipment such as IV bags, syringes, and medical tubing.

5. Construction industry: Blow molding machines are used to produce large plastic tanks, pipes, and other construction materials.

6. Agriculture industry: Agricultural products such as irrigation pipes, water tanks, and seedling trays are produced using blow molding machines.

7. Electronics industry: Blow molding machines are used to produce plastic casings and components for electronic devices.

8. Furniture industry: Blow molding machines are used to produce plastic furniture components such as chairs, tables, and storage units.

9. Sports and recreation industry: Many sports and recreation products such as kayaks, surfboards, and playground equipment are made using blow molding machines.

10. Aerospace industry: Blow molding machines are used to produce lightweight and durable components for aircraft and spacecraft.

Tags: china multiple layer blow molding machine,easteel blow molding extrusion injection,industial preform blow molding machine