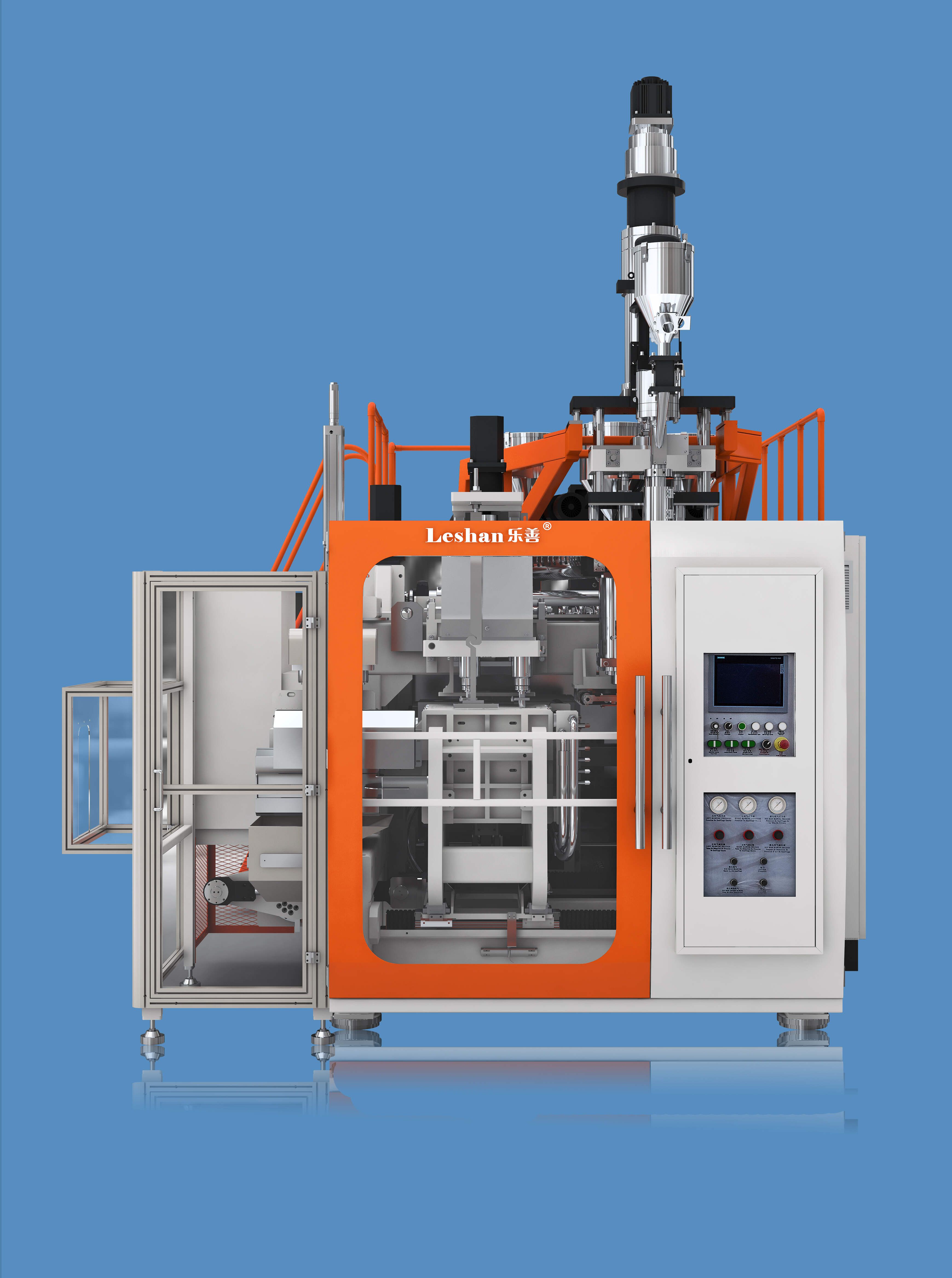

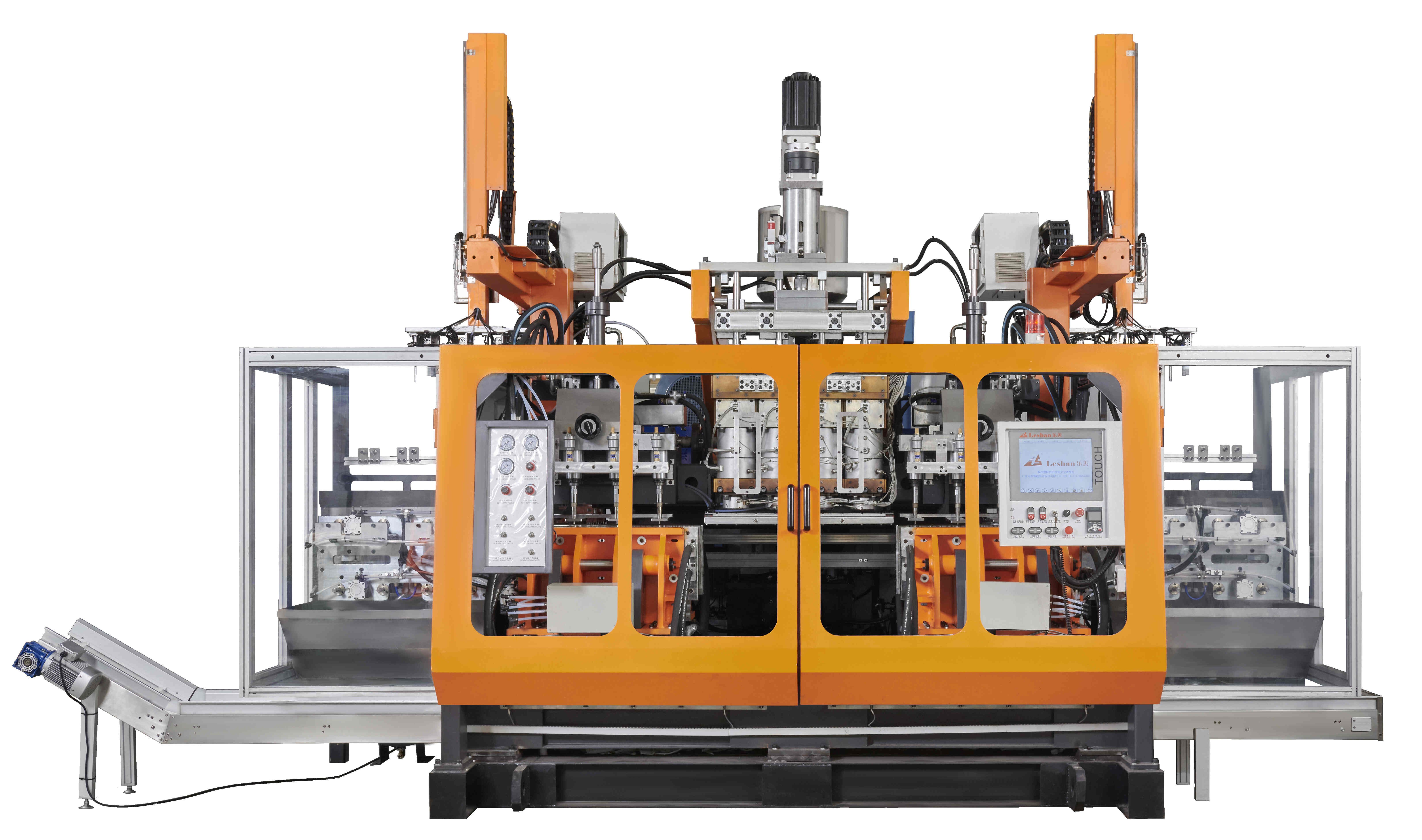

abs blow molding machine

abs blow molding machine

Guangdong Leshan Intelligent Equipment Corp.,Ltd is a professional enterprise that produces blow molding machines. Our factory is located in Foshan City, close to both Guangzhou and Shenzhen. We have an experienced team in technology research and development, manufacturing, sales, installation, and after-sales service. Our products mainly include Food bottle blow molding machine,Auxiliary machine,Engine oil bottle blow molding machine,Extrusion Die Head,Daily chemistry bottle blow molding machine,athlon series hydraulic machine,Blowing Mould & Injection Mould,Chemical barrel blow molding machine,PET Machine, etc.

Our company brought in the Germanic technical 3D scanner which is exclusive used for mold-designing . The advanced Leshan Blow Molding Machine working with the superior Leshan Mould makes the production speed faster and the production quality the topest.We use International standards and the ISO9001:2012 quality management system in producing.Our Hydraulic Blow Molding Machine is adopted by many listed companies, such as Wahaha,Yili,Cnice,Walch,Sinopec,Unilever,Monarch,Liby,Kunlun, ect.

| Parameter | Information |

|---|---|

| Product Name | abs blow molding machine |

| Brand Name | Leshan |

| Place of Origin | Foshan,Guangdong |

| Plastic Processed | Polystyrene,PVC,PE,EVA,PC,HDPE,ABS...etc |

| Air Pressure(MPa) | 0.8 MPa |

| Color | Customized Color |

| Delivery Time | 45 days |

| Port | ShunDe/GuangZhou/ShenZhen China |

| Export region | America,Africa,Asia |

| Export Country | Russia, Australia, Poland,Svalbard,Andorra,San Marino...etc |

| Application | Bottle |

| OEM/ODM | Yes |

| Core Components | Motor,PLC,Gearbox,Bearing,Gear...etc |

| Voltage | 380V |

| Service | Field maintenance and repair service... |

| MOQ | 1 set |

| Certification | ISO9001,CE... |

| Supply Ability | 500 Set/Sets per Month |

| Weight (T) | 5-18(According to specific model) |

| Packaging Details | Standard exporting machine packing with plastic film |

| Lead time (days) | 70 (To be negotiated) |

Please note: The above table data is for reference only. For specific information, please contact us.

abs blow molding machine is suitable for processing a variety of plastics, such as polyethylene, polypropylene, polyvinyl chloride, etc. These plastics can be made into various shapes of containers through different processing methods, such as bottles, barrels, boxes, etc. The blow molding machine can also realize products of different thicknesses by adjusting the design and structure of the mold, thereby adapting the products to different needs.

abs blow molding machine---FAQs Guide

2.Is there a limit to the size range of abs blow molding machine?

3.How to prevent air leakage in abs blow molding machine?

4.What are the common problems in the production process of abs blow molding machine?

5.What products are typically manufactured using abs blow molding machine?

6.Does a plastic blow dryer make PETG or Triton bottles?

7.How to choose the mold head of a abs blow molding machine?

8.How to install the machine and use the abs blow molding machine?

9.How to choose a abs blow molding machine that suits your own craft?

10.What is the operating cost of a abs blow molding machine?

11.What are the advantages of Leshan blow molding machine?

12.What is the working principle of a blow molding machine?

1.How long does it usually take to troubleshoot abs blow molding machine?

Our mission is to provide customers with the best solutions for abs blow molding machine.

The time it takes to troubleshoot a blow molding machine can vary depending on the specific issue and the experience of the technician. In some cases, it may only take a few minutes to identify and fix the problem, while in more complex cases it may take several hours or even days to fully troubleshoot and resolve the issue. It is important to thoroughly diagnose and address any problems with the machine to ensure it is functioning properly and producing high-quality products.

2.Is there a limit to the size range of abs blow molding machine?

We continue to invest in research and development and continue to launch innovative products.

Yes, there is a limit to the size range of blow molding machines. The size range of blow molding machines is typically determined by the maximum volume of the mold cavity and the maximum clamping force of the machine. The maximum volume of the mold cavity can range from a few milliliters to several liters, while the maximum clamping force can range from a few tons to several hundred tons.

Therefore, the size range of blow molding machines can vary greatly depending on the specific machine and its capabilities. Generally, blow molding machines are used to produce plastic products ranging from small bottles and containers to larger items such as automotive parts and large industrial containers.

3.How to prevent air leakage in abs blow molding machine?

We should perform well in market competition, and the prices of abs blow molding machine products have a great competitive advantage.

1. Regular Maintenance: Regular maintenance of the blow molding machine is essential to prevent air leakage. This includes checking and replacing worn out seals, gaskets, and other components that may contribute to air leakage.

2. Proper Lubrication: Lubrication of moving parts is important to ensure smooth operation of the machine and prevent air leakage. Make sure to use the recommended lubricants and follow the manufacturer's instructions for lubrication intervals.

3. Check Air Hoses and Fittings: Inspect the air hoses and fittings for any cracks, tears, or loose connections. Replace any damaged parts immediately to prevent air leakage.

4. Use High-Quality Components: Using high-quality components, such as valves, seals, and gaskets, can help prevent air leakage in the blow molding machine. These components are designed to withstand high pressures and are less likely to fail.

5. Adjust Air Pressure: Make sure to adjust the air pressure according to the manufacturer's recommendations. Too much or too little air pressure can cause air leakage in the machine.

6. Properly Align Parts: Misaligned parts can cause air leakage in the blow molding machine. Make sure all parts are properly aligned and tightened to prevent air from escaping.

7. Regularly Inspect the Machine: Regularly inspect the machine for any signs of air leakage, such as hissing sounds or drops in air pressure. If any issues are found, address them immediately to prevent further air leakage.

8. Train Operators: Properly trained operators can help prevent air leakage by operating the machine correctly and identifying any potential issues before they become major problems.

9. Use Air Leak Detection Systems: Consider using air leak detection systems to identify and locate any air leaks in the machine. This can help prevent air leakage and improve the overall efficiency of the machine.

10. Replace Worn Out Parts: Over time, parts of the blow molding machine may wear out and contribute to air leakage. It is important to regularly replace these parts to maintain the integrity of the machine and prevent air leakage.

4.What are the common problems in the production process of abs blow molding machine?

As one of the abs blow molding machine market leaders, we are known for innovation and reliability.

1. Inconsistent Wall Thickness: This is a common problem in blow molding machines where the thickness of the plastic material is not uniform throughout the product. This can lead to weak spots in the product and affect its overall strength and durability.

2. Flashing: Flashing occurs when excess plastic material leaks out of the mold during the production process. This can result in a rough or uneven surface on the final product, affecting its appearance and functionality.

3. Warping: Warping is a common problem in blow molding machines where the product becomes distorted or deformed during the cooling process. This can be caused by uneven cooling or improper mold design.

4. Air Traps: Air traps occur when air gets trapped inside the mold during the production process. This can result in air bubbles or voids in the final product, affecting its strength and appearance.

5. Poor Surface Finish: Poor surface finish can be caused by a variety of factors, including improper mold design, poor quality plastic material, or inadequate cooling. This can result in a rough or uneven surface on the final product.

6. Leaks: Leaks can occur in blow molding machines due to worn or damaged seals, improper alignment of the mold, or inadequate clamping force. This can result in product defects and production downtime.

7. Contamination: Contamination can occur in the production process when foreign particles or impurities get mixed in with the plastic material. This can result in defects in the final product and affect its quality and functionality.

8. Machine Malfunctions: Like any other machinery, blow molding machines can experience malfunctions such as electrical issues, mechanical failures, or software glitches. These can result in production delays and affect the overall efficiency of the production process.

5.What products are typically manufactured using abs blow molding machine?

Our products & services cover a wide range of areas and meet the needs of different fields.

1. Plastic bottles and containers: Blow molding machines are commonly used to produce plastic bottles and containers of various sizes and shapes, such as water bottles, shampoo bottles, and food containers.

2. Automotive components: Many automotive parts, such as fuel tanks, air ducts, and bumpers, are manufactured using blow molding machines.

3. Toys: Blow molding machines are used to produce a wide range of plastic toys, including balls, action figures, and building blocks.

4. Household products: Items such as laundry baskets, storage bins, and trash cans are often made using blow molding machines.

5. Medical equipment: Many medical devices, such as IV bags, syringes, and respiratory masks, are manufactured using blow molding machines.

6. Packaging materials: Blow molding machines are used to produce packaging materials such as plastic bags, pouches, and containers for food and other consumer products.

7. Industrial and agricultural products: Large containers, drums, and tanks used in industrial and agricultural settings are often made using blow molding machines.

8. Sports equipment: Blow molding machines are used to produce a variety of sports equipment, including footballs, soccer balls, and hockey sticks.

9. Furniture: Some types of furniture, such as chairs and tables, are made using blow molding machines to create lightweight and durable plastic components.

10. Construction materials: Blow molding machines are used to produce pipes, tubes, and other construction materials made from plastic.

6.Does a plastic blow dryer make PETG or Triton bottles?

Yes, the plastic blow molding machine of Leshan can make PETG and Triton bottles, and their blow molding machine can also make quadruple die heads.

7.How to choose the mold head of a abs blow molding machine?

We pay attention to the introduction and training of talents, scientifically regulate the management system, and focus on cultural construction and team cohesion.

1. Determine the type of blow molding machine: The first step in choosing the mold head is to determine the type of blow molding machine you have. There are three main types of blow molding machines: extrusion blow molding, injection blow molding, and stretch blow molding. Each type requires a different type of mold head.

2. Consider the material: The material you will be using for your product is also an important factor in choosing the mold head. Different materials have different properties and require different mold heads. For example, if you are using a high-density polyethylene (HDPE) material, you will need a mold head with a larger opening to accommodate the material's higher melt flow rate.

3. Determine the shape and size of the product: The shape and size of the product you want to produce will also play a role in choosing the mold head. The mold head needs to be able to create the desired shape and size of the product. If you are producing a complex shape, you may need a mold head with multiple cavities or a custom-made mold head.

4. Consider the production volume: The production volume also needs to be taken into account when choosing the mold head. If you are producing a large volume of products, you may need a mold head with multiple cavities to increase production efficiency.

5. Check the compatibility with the machine: It is important to ensure that the mold head you choose is compatible with your blow molding machine. The mold head needs to fit securely and work seamlessly with the machine to produce high-quality products.

6. Look for quality and durability: The mold head is a crucial component of the blow molding process, and it is important to choose one that is of high quality and durable. Look for mold heads made from high-quality materials and with a good track record of performance.

7. Consider the cost: The cost of the mold head is also an important factor to consider. While it is important to choose a high-quality and durable mold head, it is also important to stay within your budget. Compare prices from different suppliers and choose one that offers a good balance of quality and cost.

8. Consult with experts: If you are unsure about which mold head to choose, it is always a good idea to consult with experts in the field. They can provide valuable insights and recommendations based on your specific needs and requirements.

8.How to install the machine and use the abs blow molding machine?

We can send engineer to your factory for worker training and machine installation.

9.How to choose a abs blow molding machine that suits your own craft?

We continue to improve abs blow molding machine products and processes to improve efficiency.

1. Determine the type of blow molding process: There are three main types of blow molding processes - extrusion blow molding, injection blow molding, and stretch blow molding. Each process has its own advantages and is suitable for different types of products. Determine which process is most suitable for your product before choosing a machine.

2. Consider the size and shape of your product: Blow molding machines come in different sizes and have different capabilities. Consider the size and shape of your product to determine the size and type of machine you need. For example, if you are producing large containers, you will need a machine with a larger clamping force and a larger mold size.

3. Look for a reputable manufacturer: It is important to choose a reputable manufacturer when buying a blow molding machine. Look for manufacturers with a good track record and positive reviews from other customers. This will ensure that you get a high-quality machine that is reliable and durable.

4. Check the machine's features and capabilities: Different blow molding machines come with different features and capabilities. Some machines may have advanced features such as multi-layer co-extrusion, while others may have simpler features. Consider the features that are important for your production process and choose a machine that meets your requirements.

5. Consider the production volume: The production volume of your product will also play a role in choosing the right blow molding machine. If you have a high production volume, you will need a machine with a higher output and faster cycle times. On the other hand, if you have a lower production volume, a smaller machine with a lower output may be more suitable.

6. Look for after-sales support: It is important to choose a manufacturer that offers good after-sales support. This includes technical support, spare parts availability, and maintenance services. A good after-sales support system will ensure that your machine runs smoothly and any issues are resolved quickly.

7. Consider your budget: Blow molding machines can be a significant investment, so it is important to consider your budget when choosing a machine. However, it is also important to keep in mind that a cheaper machine may not always be the best option in terms of quality and performance. Consider the long-term benefits and ROI when making your decision.

8. Test the machine: If possible, visit the manufacturer's facility and test the machine before making a purchase. This will give you a better understanding of the machine's capabilities and help you make an informed decision.

9. Seek expert advice: If you are new to blow molding, it is advisable to seek advice from experts in the industry. They can provide valuable insights and help you choose a machine that is suitable for your specific needs.

10. Consider future growth: It is important to consider your future growth plans when choosing a blow molding machine. Choose a machine that can accommodate your future production needs and can be upgraded if necessary. This will save you from having to invest in a new machine in the future.

10.What is the operating cost of a abs blow molding machine?

We attach importance to the innovation ability and team spirit of employees, have advanced R & D facilities and laboratories, and have a good quality management system.

The operating cost of a blow molding machine can vary depending on factors such as the size and type of machine, the materials being used, and the production volume. However, some common operating costs include:

1. Energy costs: Blow molding machines require a significant amount of energy to operate, including electricity for heating and cooling processes. The cost of energy can vary depending on the location and the efficiency of the machine.

2. Labor costs: The cost of labor includes the wages of operators and technicians who run the machine, as well as any maintenance or repair personnel.

3. Material costs: The cost of materials, such as plastic resins, can vary depending on the type and quality of the material being used.

4. Maintenance and repair costs: Regular maintenance and occasional repairs are necessary to keep the machine running smoothly, and these costs should be factored into the overall operating cost.

5. Overhead costs: This includes expenses such as rent, insurance, and administrative costs that are necessary for the operation of the machine.

Overall, the operating cost of a blow molding machine can range from a few hundred dollars per day for a small machine to thousands of dollars per day for a large, high-volume machine.

11.What are the advantages of Leshan blow molding machine?

High cost performance, moderate price, more after-sales service coverage, high insurance rate, strong durability of the machine.

12.What is the working principle of a blow molding machine?

We focus on innovation and continuous improvement to maintain a competitive advantage.

The working principle of a blow molding machine involves the use of compressed air to inflate a molten plastic tube or parison inside a mold cavity. This creates a hollow shape that is then cooled and solidified to form a plastic product.

The process begins with the plastic material, usually in the form of pellets, being fed into a hopper and then melted in an extruder. The molten plastic is then forced into a long tube or parison, which is then clamped between two halves of a mold.

Next, a nozzle is inserted into the parison and compressed air is blown into it, causing the plastic to expand and take the shape of the mold cavity. The mold is cooled to solidify the plastic, and then the mold halves are separated, and the finished product is ejected.

The blow molding process can be either extrusion blow molding or injection blow molding, depending on the type of machine used. In extrusion blow molding, the parison is formed by extruding the molten plastic through a die, while in injection blow molding, the parison is formed by injecting the molten plastic into a mold cavity.

The working principle of a blow molding machine is based on the principles of thermodynamics and fluid mechanics, where the expansion of compressed air inside the parison creates pressure that forces the plastic to take the shape of the mold. This process allows for the production of hollow plastic products with complex shapes and sizes.

Tags: oil blow molding machine,china solar panel blow molding machine,tongda blow molding machine,blow extrusion molding