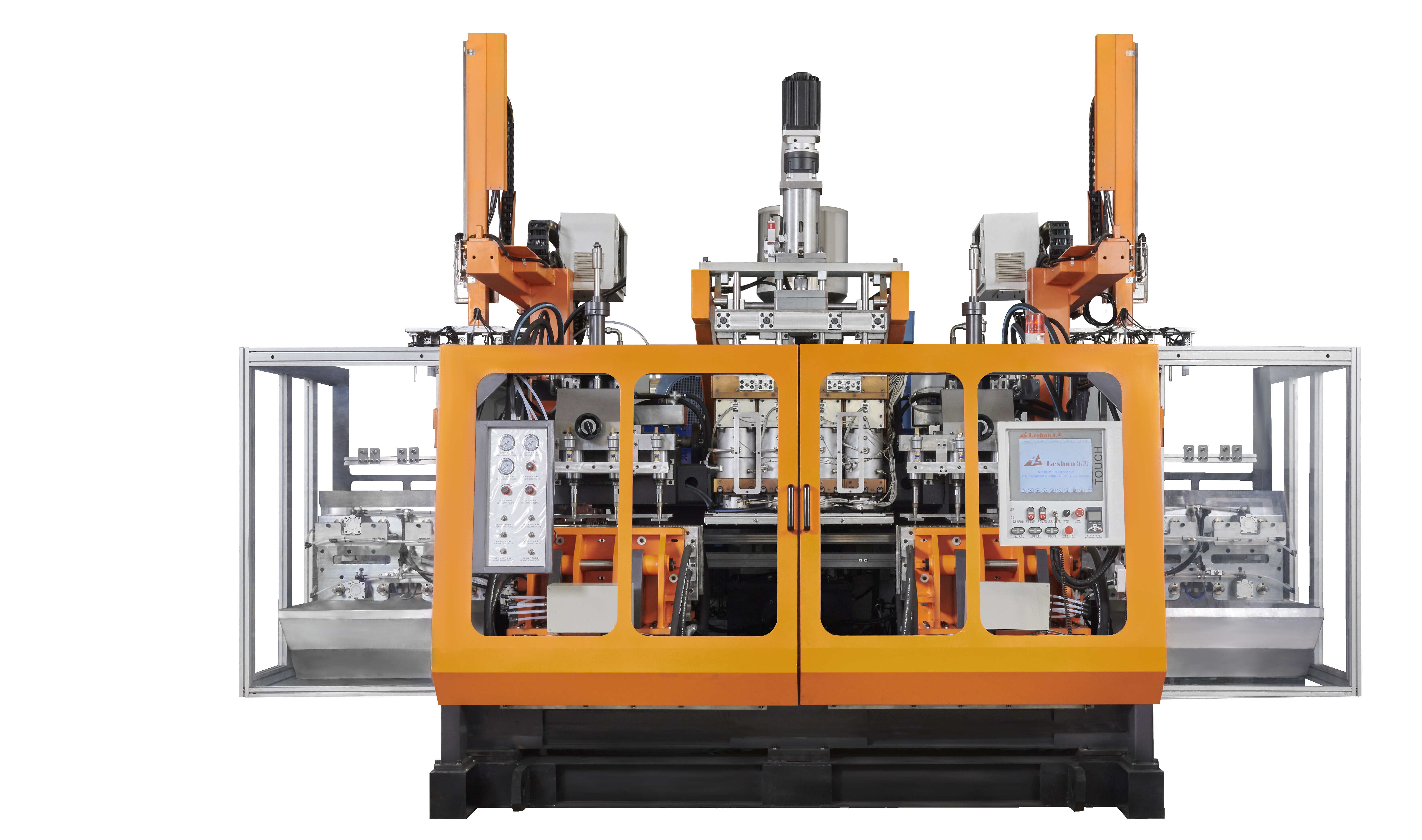

6l blow molding machine

6l blow molding machine

Leshan Intelligent Equipment Company is an enterprise that produces plastic machinery molds. Main products: Blowing Mould & Injection Mould,Extrusion Die Head,Chemical barrel blow molding machine,Engine oil bottle blow molding machine,Milk bottle blow molding machine,Daily chemistry bottle blow molding machine,Auxiliary machine,multi-layer coextrusion blow molding machine,athlon series hydraulic machine,PET Machine, etc. We have professional equipment such as Numerically controlled lathe,Pentahedron gantry machining center,Numerical-controlled cutting machine,Numerical-controlled knee bend machine,Vertical CNC gantry machining-center.

Good quality, reasonable price, fashionable design, widely recognized and trusted by users, able to meet the constantly developing economic and social needs. Our products are not only popular in China, but also exported to regions such as Asia,Oceania,Europe , as well as countries such as Russia, Australia, Poland, and Czech Republic,Guyana,Venezuela,Tanzania .

| Parameter | Information |

| Product Name | 6l blow molding machine |

| Brand Name | Leshan |

| Place of Origin | Foshan,Guangdong |

| PLC Brand | Siemens |

| Core Components | Gear,Bearing,Pressure vessel,Gearbox,Pump...etc |

| Warranty | 1year |

| Plastic Processed | EVA,PVC,PA,Polystyrene,PP,ABS,HDPE...etc |

| Application | Bottle |

| Port | ShunDe/GuangZhou/ShenZhen China |

| MOQ | 1 Set |

| Export Country | Russia, Australia, Poland,Tunisia,France,Montserrat...etc |

| Export region | Europe,Oceania,Asia... |

| Certification | ISO 9001,CE...etc |

| Automatic | Yes |

| Screw L/D Ratio | 24 |

| Packaging Details | Standard exporting machine packing with plastic film |

| Color | Customized |

| Accumulator Capacity(L) | 100 L |

| Service | Video technical support... |

| Supply Ability | 500 Set/Sets per Month |

| Lead time (days) | 70 (To be negotiated) |

Please note: The above table data is for reference only. For specific information, please contact us.

6l blow molding machine is an indispensable and important equipment in modern plastic manufacturing industry, and its characteristics are constantly being improved and developed. Future blow molding machines will be more intelligent, energy-saving and environmentally friendly, and have more additional functions to meet changing market demands. At the same time, with the introduction of new degradable plastics, blow molding machines will also adapt to the processing of new materials, promoting the development of the plastic products industry in a more environmentally friendly and sustainable direction.

6l blow molding machine---FAQs Guide

2.How to adjust the production speed of 6l blow molding machine?

3.Does a plastic blow dryer make PETG or Triton bottles?

4.How to choose a 6l blow molding machine that suits your own craft?

5.How to maintain the stability of 6l blow molding machine?

6.What are the safety standards for 6l blow molding machine?

7.How to solve the malfunction of the 6l blow molding machine?

8.What is the after-sales service for 6l blow molding machine?

9.How to choose the mold head of a 6l blow molding machine?

10.What products are typically manufactured using 6l blow molding machine?

1.What is the cost composition of 6l blow molding machine?

We focus on providing high 6l blow molding machine quality products and services.

The cost composition of blow molding machines can vary depending on the type and size of the machine, as well as the manufacturer and country of origin. However, the general cost composition can be broken down into the following components:

1. Machine base: This includes the main frame, base plate, and other structural components of the machine. It typically accounts for 20-30% of the total cost.

2. Extruder: The extruder is the heart of the blow molding machine and is responsible for melting and shaping the plastic material. It can account for 30-40% of the total cost.

3. Molds: Molds are used to shape the plastic material into the desired product. The cost of molds can vary greatly depending on the complexity and size of the product being produced. It can account for 20-30% of the total cost.

4. Control system: The control system includes the electrical and electronic components that control the operation of the machine. It can account for 10-15% of the total cost.

5. Hydraulic system: The hydraulic system is responsible for providing the necessary pressure and power to operate the machine. It can account for 5-10% of the total cost.

6. Other components: Other components such as motors, pumps, valves, and sensors can also contribute to the overall cost of the machine.

In addition to these components, the cost of blow molding machines may also include expenses such as labor, transportation, and installation. It is important to note that the cost composition may vary depending on the specific features and capabilities of the machine.

2.How to adjust the production speed of 6l blow molding machine?

Our 6l blow molding machine products undergo strict quality control to ensure customer satisfaction.

1. Check the machine settings: The first step in adjusting the production speed of a blow molding machine is to check the machine settings. Make sure that the machine is set to the desired production speed and that all the necessary adjustments have been made.

2. Adjust the air pressure: The air pressure is a crucial factor in the production speed of a blow molding machine. Increasing the air pressure can help to speed up the production process, while decreasing it can slow it down. Adjust the air pressure according to the desired production speed.

3. Change the mold: The size and shape of the mold can also affect the production speed. A larger or more complex mold will take longer to produce, while a smaller and simpler mold will speed up the production process. Consider changing the mold to one that is more suitable for the desired production speed.

4. Increase or decrease the parison size: The parison is the hollow tube of plastic that is formed in the machine and then blown into the mold. Adjusting the size of the parison can also affect the production speed. Increasing the parison size will result in a larger product and slower production, while decreasing the parison size will result in a smaller product and faster production.

5. Adjust the cooling time: The cooling time is the amount of time the product spends in the mold to solidify. Increasing the cooling time will slow down the production speed, while decreasing it will speed it up. Adjust the cooling time according to the desired production speed.

6. Check for any mechanical issues: If the production speed is not adjusting as expected, it is important to check for any mechanical issues with the machine. Make sure that all the components are functioning properly and that there are no obstructions or malfunctions that could be slowing down the production speed.

7. Test and adjust: Once all the necessary adjustments have been made, run a test production to see if the desired speed has been achieved. If not, make further adjustments until the desired production speed is reached.

It is important to note that adjusting the production speed of a blow molding machine may require some trial and error. It is recommended to make small adjustments at a time and test the results before making further adjustments.

3.Does a plastic blow dryer make PETG or Triton bottles?

Yes, the plastic blow molding machine of Leshan can make PETG and Triton bottles, and their blow molding machine can also make quadruple die heads.

4.How to choose a 6l blow molding machine that suits your own craft?

We continue to improve 6l blow molding machine products and processes to improve efficiency.

1. Determine the type of blow molding process: There are three main types of blow molding processes - extrusion blow molding, injection blow molding, and stretch blow molding. Each process has its own advantages and is suitable for different types of products. Determine which process is most suitable for your product before choosing a machine.

2. Consider the size and shape of your product: Blow molding machines come in different sizes and have different capabilities. Consider the size and shape of your product to determine the size and type of machine you need. For example, if you are producing large containers, you will need a machine with a larger clamping force and a larger mold size.

3. Look for a reputable manufacturer: It is important to choose a reputable manufacturer when buying a blow molding machine. Look for manufacturers with a good track record and positive reviews from other customers. This will ensure that you get a high-quality machine that is reliable and durable.

4. Check the machine's features and capabilities: Different blow molding machines come with different features and capabilities. Some machines may have advanced features such as multi-layer co-extrusion, while others may have simpler features. Consider the features that are important for your production process and choose a machine that meets your requirements.

5. Consider the production volume: The production volume of your product will also play a role in choosing the right blow molding machine. If you have a high production volume, you will need a machine with a higher output and faster cycle times. On the other hand, if you have a lower production volume, a smaller machine with a lower output may be more suitable.

6. Look for after-sales support: It is important to choose a manufacturer that offers good after-sales support. This includes technical support, spare parts availability, and maintenance services. A good after-sales support system will ensure that your machine runs smoothly and any issues are resolved quickly.

7. Consider your budget: Blow molding machines can be a significant investment, so it is important to consider your budget when choosing a machine. However, it is also important to keep in mind that a cheaper machine may not always be the best option in terms of quality and performance. Consider the long-term benefits and ROI when making your decision.

8. Test the machine: If possible, visit the manufacturer's facility and test the machine before making a purchase. This will give you a better understanding of the machine's capabilities and help you make an informed decision.

9. Seek expert advice: If you are new to blow molding, it is advisable to seek advice from experts in the industry. They can provide valuable insights and help you choose a machine that is suitable for your specific needs.

10. Consider future growth: It is important to consider your future growth plans when choosing a blow molding machine. Choose a machine that can accommodate your future production needs and can be upgraded if necessary. This will save you from having to invest in a new machine in the future.

5.How to maintain the stability of 6l blow molding machine?

We enjoy high authority and influence in the industry and continue to innovate products and service models.

1. Regular Maintenance: Regular maintenance is crucial for the stability of blow molding machines. This includes cleaning, lubricating, and inspecting the machine on a regular basis. Any worn or damaged parts should be replaced immediately to prevent further damage.

2. Proper Training: Ensure that all operators are properly trained on how to operate the blow molding machine. This will help prevent any accidents or damage to the machine due to operator error.

3. Use Quality Materials: The quality of the materials used in the blow molding process can affect the stability of the machine. Using high-quality materials will reduce the risk of machine breakdowns and improve the overall performance.

4. Monitor Machine Performance: Keep a close eye on the performance of the machine. This includes monitoring the temperature, pressure, and speed of the machine. Any abnormalities should be addressed immediately to prevent further damage.

5. Regular Inspections: Regularly inspect the machine for any signs of wear and tear. This will help identify any potential issues before they become major problems.

6. Follow Manufacturer's Guidelines: Follow the manufacturer's guidelines for operating and maintaining the machine. This will ensure that the machine is being used correctly and will help prolong its lifespan.

7. Keep the Machine Clean: A clean machine is less likely to experience breakdowns. Regularly clean the machine and remove any debris or dust that may have accumulated.

8. Proper Storage: When the machine is not in use, it should be stored in a clean and dry environment. This will help prevent any damage caused by moisture or dust.

9. Address Issues Immediately: If any issues arise with the machine, address them immediately. Ignoring problems can lead to more serious issues and can affect the stability of the machine.

10. Schedule Professional Servicing: It is important to schedule professional servicing of the machine on a regular basis. This will help identify any potential issues and ensure that the machine is running at its optimal performance.

6.What are the safety standards for 6l blow molding machine?

We are a new 6l blow molding machine manufacturer.

1. Electrical Safety: Blow molding machines should comply with all relevant electrical safety standards, such as the National Electrical Code (NEC) and the International Electrotechnical Commission (IEC) standards.

2. Machine Guarding: All moving parts of the machine should be guarded to prevent accidental contact and injuries. The guards should be securely fixed and not easily removable.

3. Emergency Stop: The machine should have an easily accessible emergency stop button that can quickly shut down the machine in case of an emergency.

4. Lockout/Tagout: The machine should have a lockout/tagout system in place to prevent accidental start-up during maintenance or repair.

5. Pressure Relief: Blow molding machines use high-pressure air to mold plastic, so they should have a pressure relief system in place to prevent over-pressurization and potential explosions.

6. Material Handling: The machine should have a safe and efficient material handling system to prevent injuries and accidents during the loading and unloading of materials.

7. Noise Control: Blow molding machines can produce high levels of noise, so they should have noise control measures in place to protect workers' hearing.

8. Fire Safety: The machine should have fire safety measures in place, such as fire extinguishers and fire alarms, to prevent and control fires.

9. Operator Training: All operators should receive proper training on how to operate the machine safely and be aware of potential hazards.

10. Regular Maintenance: The machine should undergo regular maintenance and inspections to ensure it is in good working condition and meets all safety standards.

7.How to solve the malfunction of the 6l blow molding machine?

As one of the top 6l blow molding machine manufacturers in China, we take this very seriously.

1. Check the power supply: Make sure the machine is properly connected to a stable power source. If there is a power surge or fluctuation, it can cause the machine to malfunction.

2. Inspect the air supply: The blow molding machine requires a steady supply of compressed air to function properly. Check the air compressor and make sure it is providing enough pressure and volume.

3. Check the temperature settings: The temperature of the machine's heating elements must be set correctly for the plastic to melt and form properly. Make sure the temperature settings are appropriate for the type of plastic being used.

4. Clean and lubricate the machine: Over time, dust, debris, and residue can build up on the machine, causing it to malfunction. Clean and lubricate all moving parts to ensure smooth operation.

5. Check for worn or damaged parts: Inspect all parts of the machine for wear and tear. Replace any damaged or worn parts to prevent further malfunctions.

6. Adjust the mold: If the product being produced is not forming correctly, the mold may need to be adjusted. Make sure the mold is properly aligned and tightened.

7. Consult the manual: If the above steps do not solve the problem, consult the machine's manual for troubleshooting tips and solutions specific to your machine.

8. Call a professional: If the problem persists, it may be best to call a professional technician to diagnose and repair the machine. Attempting to fix complex issues without proper knowledge and training can cause further damage.

8.What is the after-sales service for 6l blow molding machine?

We are centered on customers and always pay attention to customers' needs for 6l blow molding machine products.

The after-sales service for blow molding machines typically includes:

1. Technical support: This includes troubleshooting assistance, repair guidance, and advice on machine maintenance and operation.

2. Spare parts supply: The manufacturer or supplier should have a stock of spare parts for the blow molding machine, and be able to provide them quickly when needed.

3. Training: The manufacturer or supplier may offer training programs for operators and maintenance personnel to ensure proper use and maintenance of the machine.

4. Warranty: Most blow molding machines come with a warranty period, during which any defects or malfunctions will be repaired or replaced by the manufacturer or supplier.

5. On-site support: In case of major issues or breakdowns, the manufacturer or supplier may send a technician to the customer's site to provide on-site support and repairs.

6. Upgrades and improvements: The manufacturer or supplier may offer upgrades or improvements to the machine to enhance its performance or add new features.

7. Customer service: A good after-sales service should also include prompt and helpful customer service to address any concerns or questions the customer may have.

Overall, the after-sales service for blow molding machines should ensure that the customer's machine is running smoothly and efficiently, and any issues are resolved quickly to minimize downtime.

9.How to choose the mold head of a 6l blow molding machine?

We pay attention to the introduction and training of talents, scientifically regulate the management system, and focus on cultural construction and team cohesion.

1. Determine the type of blow molding machine: The first step in choosing the mold head is to determine the type of blow molding machine you have. There are three main types of blow molding machines: extrusion blow molding, injection blow molding, and stretch blow molding. Each type requires a different type of mold head.

2. Consider the material: The material you will be using for your product is also an important factor in choosing the mold head. Different materials have different properties and require different mold heads. For example, if you are using a high-density polyethylene (HDPE) material, you will need a mold head with a larger opening to accommodate the material's higher melt flow rate.

3. Determine the shape and size of the product: The shape and size of the product you want to produce will also play a role in choosing the mold head. The mold head needs to be able to create the desired shape and size of the product. If you are producing a complex shape, you may need a mold head with multiple cavities or a custom-made mold head.

4. Consider the production volume: The production volume also needs to be taken into account when choosing the mold head. If you are producing a large volume of products, you may need a mold head with multiple cavities to increase production efficiency.

5. Check the compatibility with the machine: It is important to ensure that the mold head you choose is compatible with your blow molding machine. The mold head needs to fit securely and work seamlessly with the machine to produce high-quality products.

6. Look for quality and durability: The mold head is a crucial component of the blow molding process, and it is important to choose one that is of high quality and durable. Look for mold heads made from high-quality materials and with a good track record of performance.

7. Consider the cost: The cost of the mold head is also an important factor to consider. While it is important to choose a high-quality and durable mold head, it is also important to stay within your budget. Compare prices from different suppliers and choose one that offers a good balance of quality and cost.

8. Consult with experts: If you are unsure about which mold head to choose, it is always a good idea to consult with experts in the field. They can provide valuable insights and recommendations based on your specific needs and requirements.

10.What products are typically manufactured using 6l blow molding machine?

Our products & services cover a wide range of areas and meet the needs of different fields.

1. Plastic bottles and containers: Blow molding machines are commonly used to produce plastic bottles and containers of various sizes and shapes, such as water bottles, shampoo bottles, and food containers.

2. Automotive components: Many automotive parts, such as fuel tanks, air ducts, and bumpers, are manufactured using blow molding machines.

3. Toys: Blow molding machines are used to produce a wide range of plastic toys, including balls, action figures, and building blocks.

4. Household products: Items such as laundry baskets, storage bins, and trash cans are often made using blow molding machines.

5. Medical equipment: Many medical devices, such as IV bags, syringes, and respiratory masks, are manufactured using blow molding machines.

6. Packaging materials: Blow molding machines are used to produce packaging materials such as plastic bags, pouches, and containers for food and other consumer products.

7. Industrial and agricultural products: Large containers, drums, and tanks used in industrial and agricultural settings are often made using blow molding machines.

8. Sports equipment: Blow molding machines are used to produce a variety of sports equipment, including footballs, soccer balls, and hockey sticks.

9. Furniture: Some types of furniture, such as chairs and tables, are made using blow molding machines to create lightweight and durable plastic components.

10. Construction materials: Blow molding machines are used to produce pipes, tubes, and other construction materials made from plastic.

Tags: impco blow molding machine,blow molding plastic machine,china three layer blow molding machine,double die head 2l blow molding machine,extrusion blow molding machine taiwan