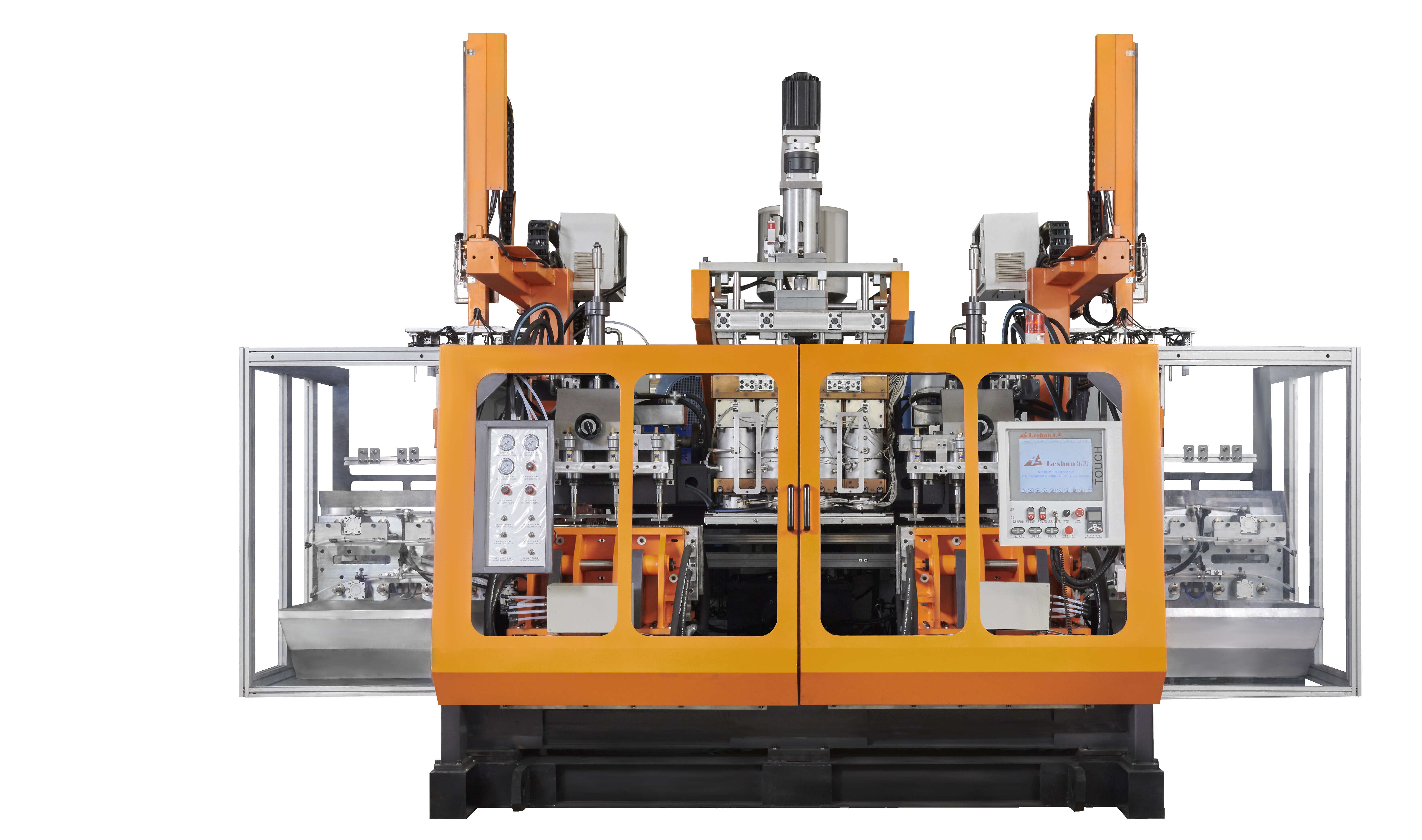

4000l blow molding machine

4000l blow molding machine

Leshan Machinery Company is a high-tech design and manufacturing company specializing in the production of blow molding machines and molds. Our products include: multi-layer coextrusion blow molding machine,athlon series hydraulic machine,Extrusion Die Head,Cleaning bottle blow molding machine,Chemical barrel blow molding machine,Irregular shape product blow molding machine,Engine oil bottle blow molding machine,PET Machine,Daily chemistry bottle blow molding machine,Milk bottle blow molding machine,Food bottle blow molding machine, etc. We will continuously strive to meet the needs of our customers and seek development together with them. At present, our products are exported to more than 50 countries and regions such as Russia, Australia, Poland, Saudi Arabia, and Bangladesh.

Our company also brought in the Germanic technical 3D scanner which is exclusive used for mold-designing . The advanced Leshan Blow Molding Machine working with the superior Leshan Mould makes the production speed faster and the production quality the topest. Leshan Hydraulic Blow Molding Machine is adopted by many listed companies and China's top 500 enterprises, such as Kunlun,Wahaha,Cnice,Walch,Yili,Bawang,Monarch,Liby,BlackCow Food, ect.

| Parameter | Information |

| Product Name | 4000l blow molding machine |

| Place of Origin | Foshan,Guangdong |

| Brand Name | Leshan |

| Condition | New |

| Video outgoing-inspection | Provided |

| Machinery Test Report | Provided |

| Warranty of core components | 1 year |

| Warranty | 1year |

| Port | ShunDe/GuangZhou/ShenZhen China |

| Application | Bottle |

| Core Components | Bearing,Gear,Pump,Pressure vessel,Gearbox,Engine...etc |

| Color | customized |

| Plastic Processed | PVC,ABS,Polystyrene,PA,PP,EVA,PE...etc |

| Certification | CE,ISO9001:2012... |

| PLC Brand | Siemens |

| Packaging Details | Standard exporting machine packing with plastic film |

| Service | Free spare parts |

| Automation | Automation |

| Supply Ability | 500 Set/Sets per year |

| Lead time (days) | 70 (To be negotiated) |

Please note: The above table data is for reference only. For specific information, please contact us.

4000l blow molding machine is suitable for processing a variety of plastics, such as polyethylene, polypropylene, polyvinyl chloride, etc. These plastics can be made into various shapes of containers through different processing methods, such as bottles, barrels, boxes, etc. The blow molding machine can also realize products of different thicknesses by adjusting the design and structure of the mold, thereby adapting the products to different needs.

4000l blow molding machine---FAQs Guide

2.What are the common problems in the production process of 4000l blow molding machine?

3.What types of blow molding machines are there?

4.How to choose the mold head of a 4000l blow molding machine?

5.How to prevent air leakage in 4000l blow molding machine?

6.How does the extrusion blow molding process differ from injection blow molding, and what types of products are typically produced using each method?

7.How to improve the production capacity and speed of 4000l blow molding machine?

8.What is the cost composition of 4000l blow molding machine?

9.Is there a limit to the size range of 4000l blow molding machine?

10.What are the advantages of Leshan blow molding machine?

1.How to optimize the efficiency of plastic blow molding machine?

It can improve the blowing process, improve the cooling water transportation of the mold, improve the machine action time, improve the shape of the cup to make the material tube become even, thus reducing the molding cycle time of the product.

2.What are the common problems in the production process of 4000l blow molding machine?

As one of the 4000l blow molding machine market leaders, we are known for innovation and reliability.

1. Inconsistent Wall Thickness: This is a common problem in blow molding machines where the thickness of the plastic material is not uniform throughout the product. This can lead to weak spots in the product and affect its overall strength and durability.

2. Flashing: Flashing occurs when excess plastic material leaks out of the mold during the production process. This can result in a rough or uneven surface on the final product, affecting its appearance and functionality.

3. Warping: Warping is a common problem in blow molding machines where the product becomes distorted or deformed during the cooling process. This can be caused by uneven cooling or improper mold design.

4. Air Traps: Air traps occur when air gets trapped inside the mold during the production process. This can result in air bubbles or voids in the final product, affecting its strength and appearance.

5. Poor Surface Finish: Poor surface finish can be caused by a variety of factors, including improper mold design, poor quality plastic material, or inadequate cooling. This can result in a rough or uneven surface on the final product.

6. Leaks: Leaks can occur in blow molding machines due to worn or damaged seals, improper alignment of the mold, or inadequate clamping force. This can result in product defects and production downtime.

7. Contamination: Contamination can occur in the production process when foreign particles or impurities get mixed in with the plastic material. This can result in defects in the final product and affect its quality and functionality.

8. Machine Malfunctions: Like any other machinery, blow molding machines can experience malfunctions such as electrical issues, mechanical failures, or software glitches. These can result in production delays and affect the overall efficiency of the production process.

3.What types of blow molding machines are there?

We should have a stable supply chain and logistics capabilities, and provide customers with high -quality, low -priced 4000l blow molding machine products.

1. Extrusion blow molding machine: This type of machine uses a continuous extrusion process to produce hollow plastic products, such as bottles, containers, and tanks.

2. Injection blow molding machine: This machine combines the processes of injection molding and blow molding to produce small, complex, and precise plastic products, such as medical devices and electronic components.

3. Stretch blow molding machine: This machine uses a two-stage process to produce high-quality, lightweight bottles and containers from PET (polyethylene terephthalate) material.

4. Reheat stretch blow molding machine: This type of machine is similar to the stretch blow molding machine, but it uses preforms (partially formed bottles) instead of raw material to produce bottles and containers.

5. Rotational blow molding machine: This machine uses a rotating mold to produce large, hollow plastic products, such as tanks, drums, and toys.

6. Shuttle blow molding machine: This machine has a shuttle system that moves the mold back and forth, allowing for the production of larger and more complex products.

7. Injection stretch blow molding machine: This machine combines the processes of injection molding and stretch blow molding to produce high-quality, lightweight bottles and containers from PET material.

8. Accumulator blow molding machine: This machine uses an accumulator to store molten plastic, which is then used to produce large and complex products, such as automotive parts and industrial containers.

9. Continuous extrusion blow molding machine: This machine uses a continuous extrusion process to produce long, tubular plastic products, such as pipes and tubes.

10. Co-extrusion blow molding machine: This machine uses multiple extruders to produce products with multiple layers, allowing for the production of complex and multi-functional products.

4.How to choose the mold head of a 4000l blow molding machine?

We pay attention to the introduction and training of talents, scientifically regulate the management system, and focus on cultural construction and team cohesion.

1. Determine the type of blow molding machine: The first step in choosing the mold head is to determine the type of blow molding machine you have. There are three main types of blow molding machines: extrusion blow molding, injection blow molding, and stretch blow molding. Each type requires a different type of mold head.

2. Consider the material: The material you will be using for your product is also an important factor in choosing the mold head. Different materials have different properties and require different mold heads. For example, if you are using a high-density polyethylene (HDPE) material, you will need a mold head with a larger opening to accommodate the material's higher melt flow rate.

3. Determine the shape and size of the product: The shape and size of the product you want to produce will also play a role in choosing the mold head. The mold head needs to be able to create the desired shape and size of the product. If you are producing a complex shape, you may need a mold head with multiple cavities or a custom-made mold head.

4. Consider the production volume: The production volume also needs to be taken into account when choosing the mold head. If you are producing a large volume of products, you may need a mold head with multiple cavities to increase production efficiency.

5. Check the compatibility with the machine: It is important to ensure that the mold head you choose is compatible with your blow molding machine. The mold head needs to fit securely and work seamlessly with the machine to produce high-quality products.

6. Look for quality and durability: The mold head is a crucial component of the blow molding process, and it is important to choose one that is of high quality and durable. Look for mold heads made from high-quality materials and with a good track record of performance.

7. Consider the cost: The cost of the mold head is also an important factor to consider. While it is important to choose a high-quality and durable mold head, it is also important to stay within your budget. Compare prices from different suppliers and choose one that offers a good balance of quality and cost.

8. Consult with experts: If you are unsure about which mold head to choose, it is always a good idea to consult with experts in the field. They can provide valuable insights and recommendations based on your specific needs and requirements.

5.How to prevent air leakage in 4000l blow molding machine?

We should perform well in market competition, and the prices of 4000l blow molding machine products have a great competitive advantage.

1. Regular Maintenance: Regular maintenance of the blow molding machine is essential to prevent air leakage. This includes checking and replacing worn out seals, gaskets, and other components that may contribute to air leakage.

2. Proper Lubrication: Lubrication of moving parts is important to ensure smooth operation of the machine and prevent air leakage. Make sure to use the recommended lubricants and follow the manufacturer's instructions for lubrication intervals.

3. Check Air Hoses and Fittings: Inspect the air hoses and fittings for any cracks, tears, or loose connections. Replace any damaged parts immediately to prevent air leakage.

4. Use High-Quality Components: Using high-quality components, such as valves, seals, and gaskets, can help prevent air leakage in the blow molding machine. These components are designed to withstand high pressures and are less likely to fail.

5. Adjust Air Pressure: Make sure to adjust the air pressure according to the manufacturer's recommendations. Too much or too little air pressure can cause air leakage in the machine.

6. Properly Align Parts: Misaligned parts can cause air leakage in the blow molding machine. Make sure all parts are properly aligned and tightened to prevent air from escaping.

7. Regularly Inspect the Machine: Regularly inspect the machine for any signs of air leakage, such as hissing sounds or drops in air pressure. If any issues are found, address them immediately to prevent further air leakage.

8. Train Operators: Properly trained operators can help prevent air leakage by operating the machine correctly and identifying any potential issues before they become major problems.

9. Use Air Leak Detection Systems: Consider using air leak detection systems to identify and locate any air leaks in the machine. This can help prevent air leakage and improve the overall efficiency of the machine.

10. Replace Worn Out Parts: Over time, parts of the blow molding machine may wear out and contribute to air leakage. It is important to regularly replace these parts to maintain the integrity of the machine and prevent air leakage.

6.How does the extrusion blow molding process differ from injection blow molding, and what types of products are typically produced using each method?

We have been working hard to improve service quality and meet customer needs.

Extrusion blow molding and injection blow molding are two different processes used to manufacture plastic products. While both methods involve melting plastic and shaping it into a desired form, there are some key differences between the two.

Extrusion blow molding is a process in which a molten tube of plastic, called a parison, is extruded through a die and then inflated to form a hollow product. The parison is then cooled and the mold opens to release the finished product. This process is commonly used to produce bottles, containers, and other hollow objects.

On the other hand, injection blow molding involves injecting molten plastic into a mold cavity, where it is then cooled and solidified. The mold then opens to release the finished product. This process is commonly used to produce small, complex, and precise products such as medical devices, pharmaceutical packaging, and small bottles.

One of the main differences between the two processes is the way the plastic is shaped. In extrusion blow molding, the plastic is shaped by the inflation of the parison, while in injection blow molding, the plastic is shaped by the mold cavity.

Another difference is the type of molds used. In extrusion blow molding, the molds are typically made of two halves that come together to form the desired shape. In injection blow molding, the molds are usually made of a single piece that is opened and closed to release the product.

The type of plastic used also differs between the two processes. Extrusion blow molding is typically used for high-density polyethylene (HDPE) and polyethylene terephthalate (PET) plastics, while injection blow molding is commonly used for polypropylene (PP) and polyethylene (PE) plastics.

In terms of product applications, extrusion blow molding is commonly used for larger, more simple products such as bottles and containers, while injection blow molding is used for smaller, more complex products such as medical devices and pharmaceutical packaging.

In summary, extrusion blow molding and injection blow molding are two different processes used to manufacture plastic products. While both methods involve melting plastic and shaping it into a desired form, they differ in the way the plastic is shaped, the type of molds used, and the types of products produced.

7.How to improve the production capacity and speed of 4000l blow molding machine?

We pay attention to user experience and product quality, and provide the best product quality and lowest production cost for cooperative customers.

1. Regular Maintenance: Regular maintenance of the blow molding machine is essential to ensure its smooth functioning and prevent breakdowns. This includes cleaning, lubricating, and replacing worn-out parts.

2. Use High-Quality Materials: The quality of the materials used in the blow molding process can greatly affect the production capacity and speed. Using high-quality materials can result in faster production and better quality products.

3. Optimize the Design: The design of the blow molding machine can also impact its production capacity and speed. Optimizing the design to reduce the number of steps and improve the efficiency of the process can increase the production speed.

4. Increase Automation: Automation can greatly improve the production capacity and speed of blow molding machines. Automated processes can reduce the need for manual labor and increase the accuracy and speed of production.

5. Use Advanced Technology: Upgrading to newer and more advanced blow molding technology can significantly improve the production capacity and speed. This includes using computer-controlled systems, advanced sensors, and other technologies that can optimize the production process.

6. Train Operators: Properly trained operators can greatly improve the efficiency and speed of the blow molding process. They should be trained in operating the machine, troubleshooting common issues, and performing routine maintenance.

7. Implement Lean Manufacturing Principles: Implementing lean manufacturing principles can help identify and eliminate waste in the production process, resulting in increased efficiency and speed.

8. Increase the Number of Cavities: Increasing the number of cavities in the blow molding machine can significantly increase the production capacity. This allows for more products to be produced in a single cycle, reducing the overall production time.

9. Optimize Cooling Time: The cooling time of the products can greatly impact the production speed. Optimizing the cooling time by using advanced cooling methods can reduce the overall production time.

10. Monitor and Analyze Production Data: Regularly monitoring and analyzing production data can help identify bottlenecks and areas for improvement. This can help optimize the production process and increase the production capacity and speed.

8.What is the cost composition of 4000l blow molding machine?

We focus on providing high 4000l blow molding machine quality products and services.

The cost composition of blow molding machines can vary depending on the type and size of the machine, as well as the manufacturer and country of origin. However, the general cost composition can be broken down into the following components:

1. Machine base: This includes the main frame, base plate, and other structural components of the machine. It typically accounts for 20-30% of the total cost.

2. Extruder: The extruder is the heart of the blow molding machine and is responsible for melting and shaping the plastic material. It can account for 30-40% of the total cost.

3. Molds: Molds are used to shape the plastic material into the desired product. The cost of molds can vary greatly depending on the complexity and size of the product being produced. It can account for 20-30% of the total cost.

4. Control system: The control system includes the electrical and electronic components that control the operation of the machine. It can account for 10-15% of the total cost.

5. Hydraulic system: The hydraulic system is responsible for providing the necessary pressure and power to operate the machine. It can account for 5-10% of the total cost.

6. Other components: Other components such as motors, pumps, valves, and sensors can also contribute to the overall cost of the machine.

In addition to these components, the cost of blow molding machines may also include expenses such as labor, transportation, and installation. It is important to note that the cost composition may vary depending on the specific features and capabilities of the machine.

9.Is there a limit to the size range of 4000l blow molding machine?

We continue to invest in research and development and continue to launch innovative products.

Yes, there is a limit to the size range of blow molding machines. The size range of blow molding machines is typically determined by the maximum volume of the mold cavity and the maximum clamping force of the machine. The maximum volume of the mold cavity can range from a few milliliters to several liters, while the maximum clamping force can range from a few tons to several hundred tons.

Therefore, the size range of blow molding machines can vary greatly depending on the specific machine and its capabilities. Generally, blow molding machines are used to produce plastic products ranging from small bottles and containers to larger items such as automotive parts and large industrial containers.

10.What are the advantages of Leshan blow molding machine?

High cost performance, moderate price, more after-sales service coverage, high insurance rate, strong durability of the machine.

Tags: 2000 liter blow molding machine,jomar blow molding machine,siapi blow molding machine,automatic hot fill blow molding machine,sidel blow mold machine