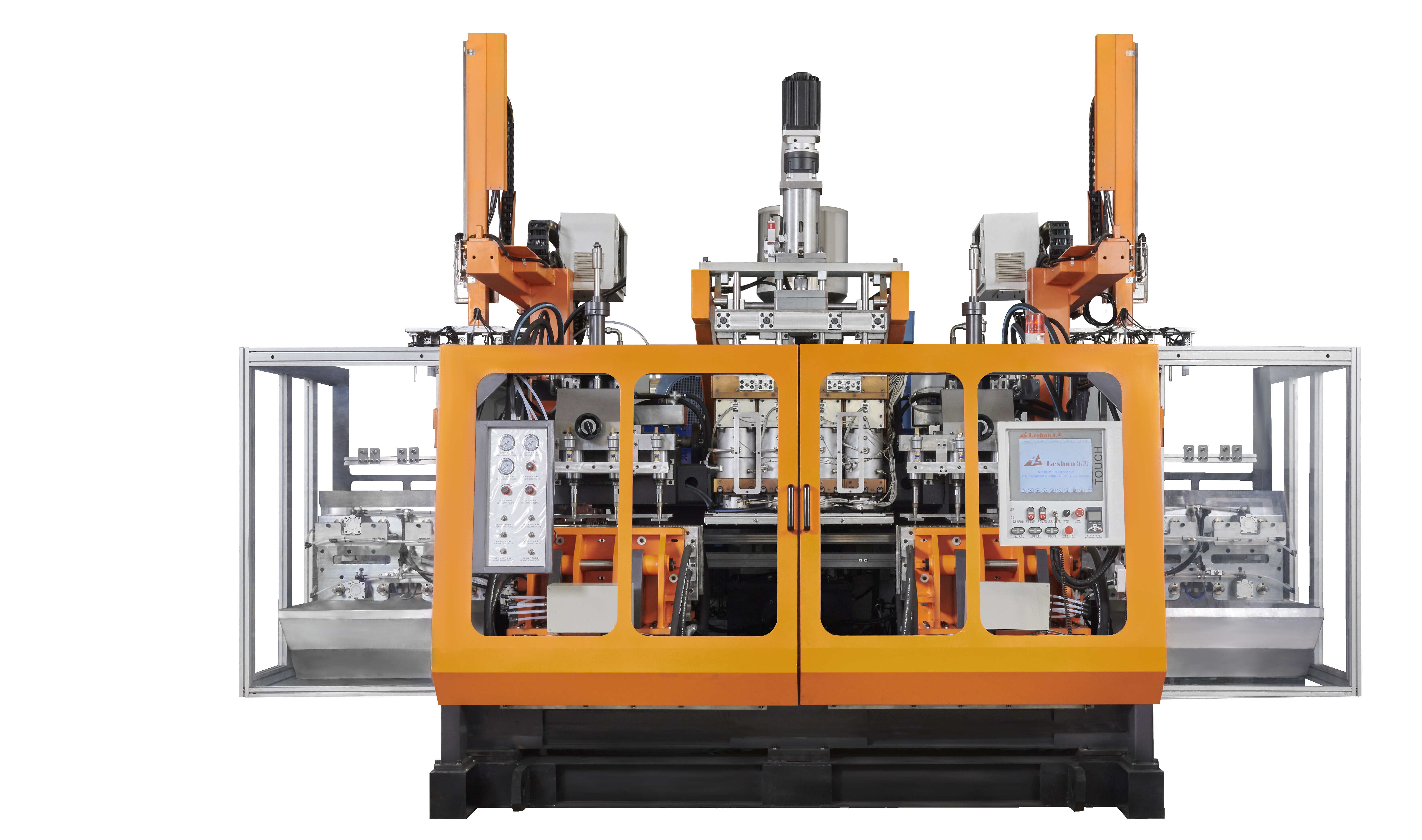

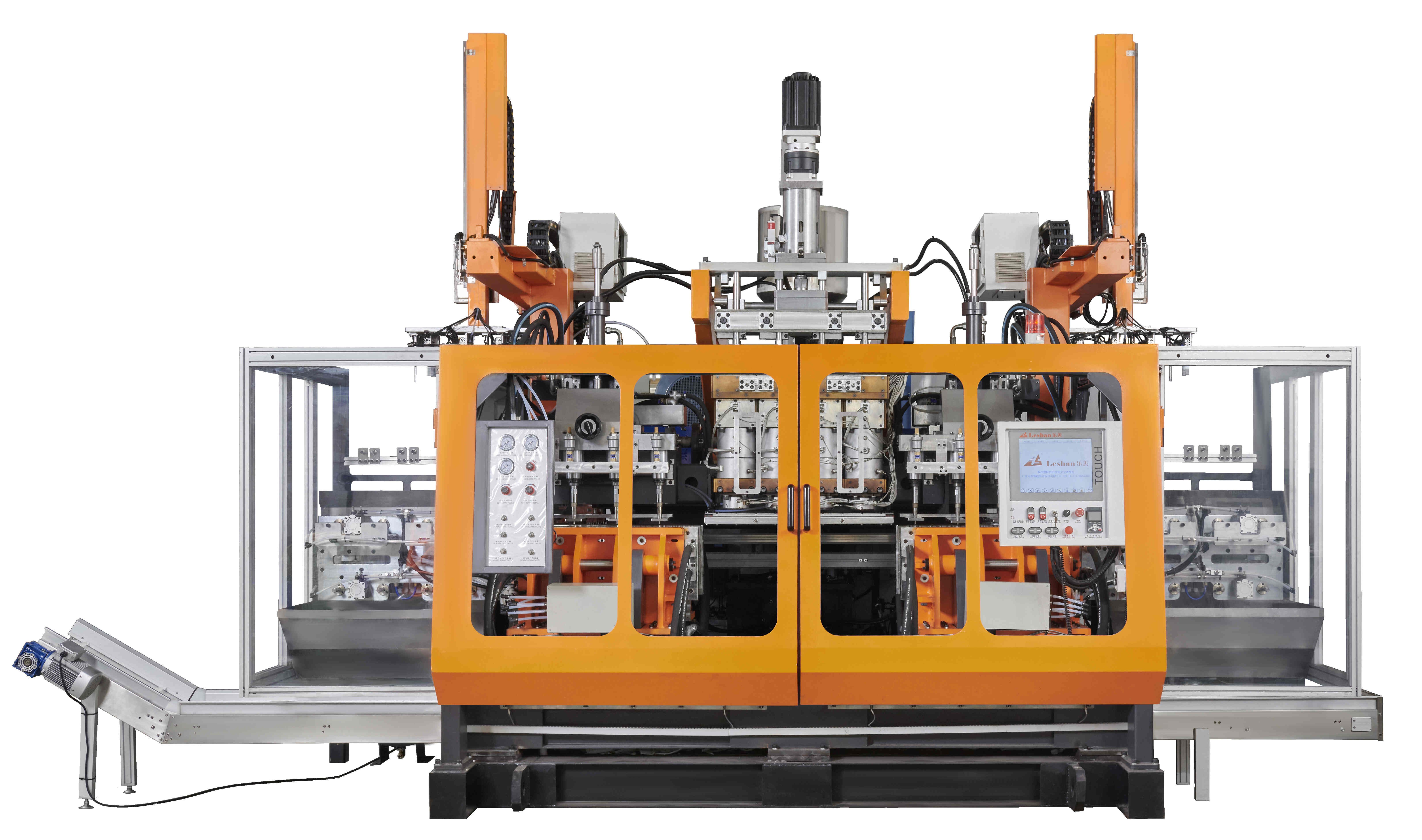

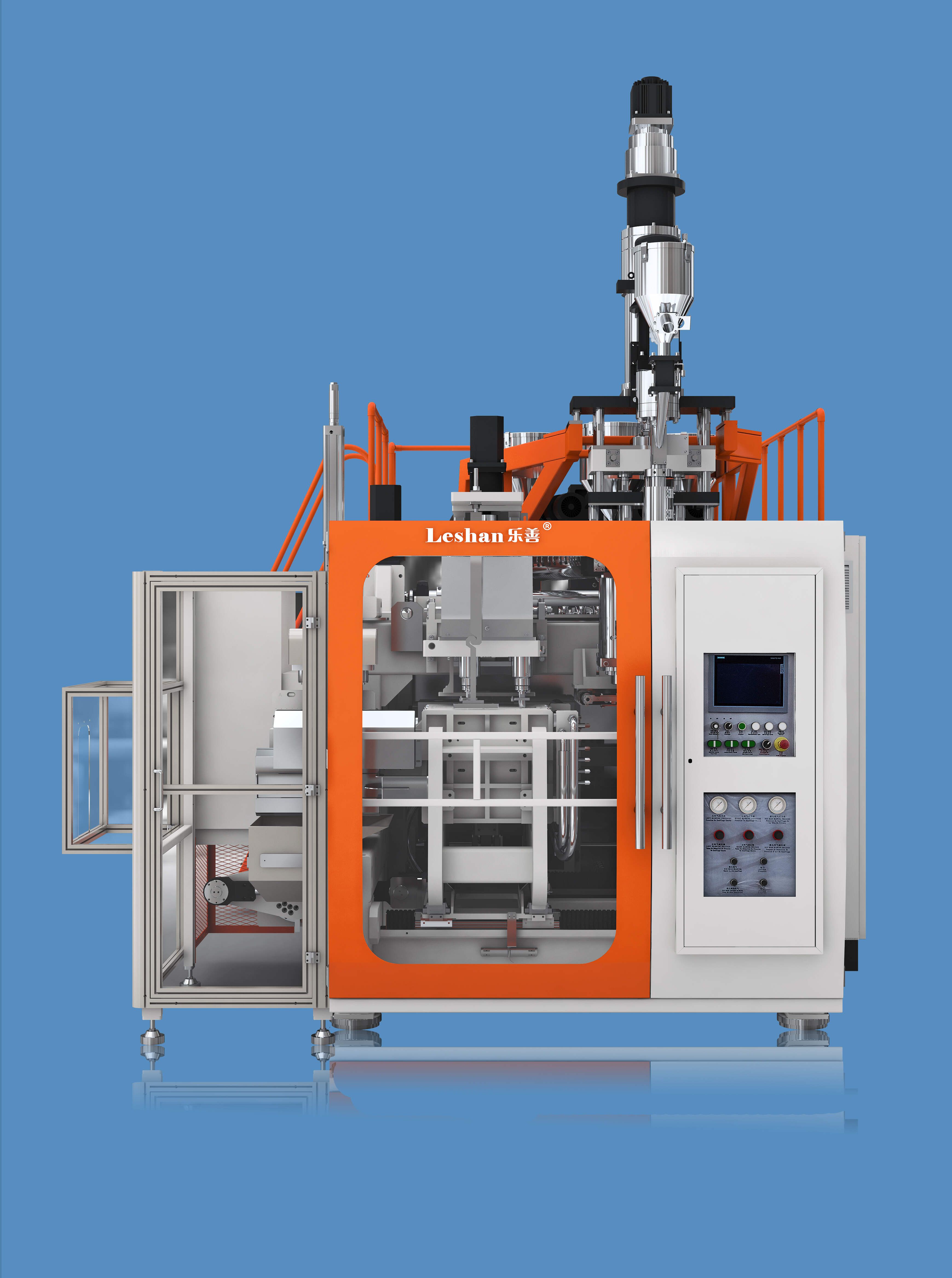

3000l blow molding machine

3000l blow molding machine

Leshan Intelligent Equipment Company is a professional manufacturer of blow molding machines that integrates research and development, design, manufacturing, technical services, and marketing. The company is located in Foshan, Guangdong, adjacent to large and medium-sized cities such as Shenzhen, Guangzhou, and Dongguan. Our products include Cleaning bottle blow molding machine,athlon series hydraulic machine,Blowing Mould & Injection Mould,Chemical barrel blow molding machine,Engine oil bottle blow molding machine,Milk bottle blow molding machine,Irregular shape product blow molding machine,PET Machine,Auxiliary machine,multi-layer coextrusion blow molding machine,Extrusion Die Head, etc.

The company's factory covers an area of over 10000 square meters and has over 300 technical and staff members. We are still adopting international standards and ISO9001:2012 quality management system in production. Therefore, the production quality, efficiency, energy consumption, and control maintenance of Leshan blow molding machines are among the top in the domestic industry, and their sales are far ahead of the domestic industry.

| Parameter | Information |

| Product Name | 3000l blow molding machine |

| Brand Name | Leshan |

| Place of Origin | Foshan,Guangdong |

| PLC Brand | Siemens |

| Core Components | Engine,Motor,Bearing,Pressure vessel,Gearbox...etc |

| Warranty | 1year |

| Plastic Processed | EVA,Polystyrene,PC,PP,PVC,HDPE...etc |

| Application | Bottle |

| Port | ShunDe/GuangZhou/ShenZhen China |

| MOQ | 1 Set |

| Export Country | Russia, Australia, Poland,North Korea,Saint Helena,Niue...etc |

| Export region | America,Europe,Oceania... |

| Certification | ISO 9001,CE...etc |

| Automatic | Yes |

| Screw L/D Ratio | 24 |

| Packaging Details | Standard exporting machine packing with plastic film |

| Color | Customized |

| Accumulator Capacity(L) | 100 L |

| Service | Field maintenance and repair service... |

| Supply Ability | 500 Set/Sets per Month |

| Lead time (days) | 70 (To be negotiated) |

Please note: The above table data is for reference only. For specific information, please contact us.

With the development of science and technology, 3000l blow molding machine have become intelligent and automated. Through the advanced control system, accurate control of various parameters, such as temperature, pressure, time, etc., can be achieved. Precise control of these parameters can ensure the stable quality of products and reduce losses during the production process.

3000l blow molding machine---FAQs Guide

2.How to control temperature and pressure during the production process of 3000l blow molding machine?

3.Can I make milk bottle on this machine?

4.How to choose a 3000l blow molding machine that suits your own craft?

5.What is the after-sales service for 3000l blow molding machine?

6.What factors will affect the production efficiency of 3000l blow molding machine?

7.How to adjust the production speed of 3000l blow molding machine?

8.Besides the blow molding machine, what other services can Leshan provide?

9.About 3000l blow molding machine,Do you provide samples? ls it free or extra?

10.How does the pressure system of a 3000l blow molding machine work?

11.What are the steps for cleaning and maintaining a 3000l blow molding machine?

1.How to design the shaping mold for 3000l blow molding machine?

We continuously upgrade our skills and knowledge to adapt to changing 3000l blow molding machine market needs.

1. Determine the shape and size of the final product: The first step in designing a shaping mold for blow molding machines is to determine the shape and size of the final product. This will help in determining the overall dimensions and features of the mold.

2. Choose the type of blow molding machine: There are different types of blow molding machines such as extrusion blow molding, injection blow molding, and stretch blow molding. Each type requires a different type of mold design, so it is important to choose the right type of machine for your product.

3. Create a 3D model of the product: Using CAD software, create a 3D model of the product to be molded. This will help in visualizing the final product and identifying any potential design issues.

4. Determine the number of cavities: The number of cavities in the mold will depend on the production volume and the size of the product. More cavities will increase the production rate, but it will also increase the complexity and cost of the mold.

5. Design the core and cavity: The core and cavity are the two main components of the mold. The core is the inner part of the mold that shapes the product, while the cavity is the outer part that gives the product its final shape. The design of these components should be precise and accurate to ensure a high-quality product.

6. Consider draft angles: Draft angles are important in blow molding as they allow the product to be easily removed from the mold. A draft angle of 3-5 degrees is recommended for most products.

7. Add cooling channels: Cooling channels are essential for maintaining the temperature of the mold during the molding process. These channels should be strategically placed to ensure uniform cooling and prevent warping of the product.

8. Include ejection system: An ejection system is used to remove the product from the mold after it has been formed. This can be in the form of pins, air blasts, or mechanical ejection systems.

9. Test and refine the design: Once the initial design is complete, it is important to test it on a prototype mold to identify any design flaws or issues. This will help in refining the design before the final mold is produced.

10. Consider material selection: The material used for the mold should be able to withstand high temperatures and pressures. Common materials used for blow molding molds include aluminum, steel, and beryllium copper.

11. Work with a professional mold maker: It is recommended to work with a professional mold maker who has experience in designing molds for blow molding machines. They can provide valuable insights and ensure that the mold is designed to meet your specific requirements.

2.How to control temperature and pressure during the production process of 3000l blow molding machine?

We focus on our customers' needs and strive to meet their expectations, so we take this very seriously.

1. Use a temperature controller: A temperature controller is an essential tool for controlling the temperature during the production process of blow molding machines. It allows you to set and maintain the desired temperature for the different stages of the process.

2. Monitor the temperature regularly: It is important to monitor the temperature of the machine regularly to ensure that it is within the desired range. This can be done using a thermometer or a temperature sensor.

3. Adjust the temperature settings: Depending on the type of material being used and the stage of the production process, the temperature settings may need to be adjusted. For example, a higher temperature may be required for melting the plastic, while a lower temperature may be needed for cooling the molded product.

4. Use a cooling system: To control the temperature during the cooling stage, a cooling system can be used. This can be in the form of a water chiller or a cooling tower, which helps to maintain a consistent temperature for the molded product.

5. Use a pressure regulator: A pressure regulator is used to control the pressure inside the machine. This is important for ensuring that the plastic is evenly distributed and that the final product has the desired shape and thickness.

6. Monitor the pressure: Just like temperature, it is important to monitor the pressure inside the machine regularly. This can be done using a pressure gauge or a pressure sensor.

7. Adjust the pressure settings: Depending on the type of material and the desired product, the pressure settings may need to be adjusted. This can be done manually or through the use of an automated pressure control system.

8. Use safety valves: Safety valves are important for maintaining the pressure within safe limits. They help to prevent any accidents or damage to the machine.

9. Train operators: It is important to train operators on how to control the temperature and pressure during the production process. They should be familiar with the different settings and know how to make adjustments when necessary.

10. Regular maintenance: Regular maintenance of the machine is crucial for ensuring that the temperature and pressure control systems are functioning properly. This will help to prevent any unexpected issues during the production process.

3.Can I make milk bottle on this machine?

Yes, you can. Milk bottle,detergent bottle,pattern pot are available on the machine.

4.How to choose a 3000l blow molding machine that suits your own craft?

We continue to improve 3000l blow molding machine products and processes to improve efficiency.

1. Determine the type of blow molding process: There are three main types of blow molding processes - extrusion blow molding, injection blow molding, and stretch blow molding. Each process has its own advantages and is suitable for different types of products. Determine which process is most suitable for your product before choosing a machine.

2. Consider the size and shape of your product: Blow molding machines come in different sizes and have different capabilities. Consider the size and shape of your product to determine the size and type of machine you need. For example, if you are producing large containers, you will need a machine with a larger clamping force and a larger mold size.

3. Look for a reputable manufacturer: It is important to choose a reputable manufacturer when buying a blow molding machine. Look for manufacturers with a good track record and positive reviews from other customers. This will ensure that you get a high-quality machine that is reliable and durable.

4. Check the machine's features and capabilities: Different blow molding machines come with different features and capabilities. Some machines may have advanced features such as multi-layer co-extrusion, while others may have simpler features. Consider the features that are important for your production process and choose a machine that meets your requirements.

5. Consider the production volume: The production volume of your product will also play a role in choosing the right blow molding machine. If you have a high production volume, you will need a machine with a higher output and faster cycle times. On the other hand, if you have a lower production volume, a smaller machine with a lower output may be more suitable.

6. Look for after-sales support: It is important to choose a manufacturer that offers good after-sales support. This includes technical support, spare parts availability, and maintenance services. A good after-sales support system will ensure that your machine runs smoothly and any issues are resolved quickly.

7. Consider your budget: Blow molding machines can be a significant investment, so it is important to consider your budget when choosing a machine. However, it is also important to keep in mind that a cheaper machine may not always be the best option in terms of quality and performance. Consider the long-term benefits and ROI when making your decision.

8. Test the machine: If possible, visit the manufacturer's facility and test the machine before making a purchase. This will give you a better understanding of the machine's capabilities and help you make an informed decision.

9. Seek expert advice: If you are new to blow molding, it is advisable to seek advice from experts in the industry. They can provide valuable insights and help you choose a machine that is suitable for your specific needs.

10. Consider future growth: It is important to consider your future growth plans when choosing a blow molding machine. Choose a machine that can accommodate your future production needs and can be upgraded if necessary. This will save you from having to invest in a new machine in the future.

5.What is the after-sales service for 3000l blow molding machine?

We are centered on customers and always pay attention to customers' needs for 3000l blow molding machine products.

The after-sales service for blow molding machines typically includes:

1. Technical support: This includes troubleshooting assistance, repair guidance, and advice on machine maintenance and operation.

2. Spare parts supply: The manufacturer or supplier should have a stock of spare parts for the blow molding machine, and be able to provide them quickly when needed.

3. Training: The manufacturer or supplier may offer training programs for operators and maintenance personnel to ensure proper use and maintenance of the machine.

4. Warranty: Most blow molding machines come with a warranty period, during which any defects or malfunctions will be repaired or replaced by the manufacturer or supplier.

5. On-site support: In case of major issues or breakdowns, the manufacturer or supplier may send a technician to the customer's site to provide on-site support and repairs.

6. Upgrades and improvements: The manufacturer or supplier may offer upgrades or improvements to the machine to enhance its performance or add new features.

7. Customer service: A good after-sales service should also include prompt and helpful customer service to address any concerns or questions the customer may have.

Overall, the after-sales service for blow molding machines should ensure that the customer's machine is running smoothly and efficiently, and any issues are resolved quickly to minimize downtime.

6.What factors will affect the production efficiency of 3000l blow molding machine?

We have a professional team that is committed to the innovation and development of 3000l blow molding machine.

1. Machine Design and Technology: The design and technology of the blow molding machine play a crucial role in its production efficiency. A well-designed machine with advanced technology can produce more products in less time.

2. Type of Material: The type of material used for blow molding can significantly affect the production efficiency. Some materials, such as HDPE, are easier to process and can result in higher production rates compared to others.

3. Mold Design and Quality: The design and quality of the mold used in the blow molding process can also impact production efficiency. A well-designed and high-quality mold can produce more consistent and precise products, resulting in higher production rates.

4. Machine Maintenance: Regular maintenance of the blow molding machine is essential to ensure its optimal performance. Neglecting maintenance can lead to breakdowns and downtime, reducing production efficiency.

5. Operator Skill and Training: The skill and training of the machine operator can also affect production efficiency. A trained and experienced operator can operate the machine more efficiently, resulting in higher production rates.

6. Production Volume and Batch Size: The production volume and batch size can also impact the production efficiency of blow molding machines. Larger production volumes and batch sizes can result in higher efficiency due to reduced setup and changeover times.

7. Ambient Conditions: The ambient conditions, such as temperature and humidity, can affect the production efficiency of blow molding machines. Extreme temperatures or high humidity can affect the quality of the products and slow down the production process.

8. Automation and Control Systems: The level of automation and control systems used in the blow molding machine can also impact production efficiency. Advanced automation and control systems can improve process control and reduce human error, resulting in higher production rates.

9. Energy Efficiency: The energy efficiency of the blow molding machine can also affect its production efficiency. Energy-efficient machines can reduce operating costs and increase production rates.

10. Quality Control: The implementation of a robust quality control system can also improve production efficiency. By identifying and addressing defects early on, the machine can produce more high-quality products in less time.

7.How to adjust the production speed of 3000l blow molding machine?

Our 3000l blow molding machine products undergo strict quality control to ensure customer satisfaction.

1. Check the machine settings: The first step in adjusting the production speed of a blow molding machine is to check the machine settings. Make sure that the machine is set to the desired production speed and that all the necessary adjustments have been made.

2. Adjust the air pressure: The air pressure is a crucial factor in the production speed of a blow molding machine. Increasing the air pressure can help to speed up the production process, while decreasing it can slow it down. Adjust the air pressure according to the desired production speed.

3. Change the mold: The size and shape of the mold can also affect the production speed. A larger or more complex mold will take longer to produce, while a smaller and simpler mold will speed up the production process. Consider changing the mold to one that is more suitable for the desired production speed.

4. Increase or decrease the parison size: The parison is the hollow tube of plastic that is formed in the machine and then blown into the mold. Adjusting the size of the parison can also affect the production speed. Increasing the parison size will result in a larger product and slower production, while decreasing the parison size will result in a smaller product and faster production.

5. Adjust the cooling time: The cooling time is the amount of time the product spends in the mold to solidify. Increasing the cooling time will slow down the production speed, while decreasing it will speed it up. Adjust the cooling time according to the desired production speed.

6. Check for any mechanical issues: If the production speed is not adjusting as expected, it is important to check for any mechanical issues with the machine. Make sure that all the components are functioning properly and that there are no obstructions or malfunctions that could be slowing down the production speed.

7. Test and adjust: Once all the necessary adjustments have been made, run a test production to see if the desired speed has been achieved. If not, make further adjustments until the desired production speed is reached.

It is important to note that adjusting the production speed of a blow molding machine may require some trial and error. It is recommended to make small adjustments at a time and test the results before making further adjustments.

8.Besides the blow molding machine, what other services can Leshan provide?

Also provide close mold, auxiliary system, key engineering services.

9.About 3000l blow molding machine,Do you provide samples? ls it free or extra?

Yes,we could offer you the sample.But it's not free.You need to pay for the sample and the cost of freight.

10.How does the pressure system of a 3000l blow molding machine work?

We have a first -class management team, and we pay attention to teamwork to achieve common goals.

The pressure system of a blow molding machine is responsible for creating and maintaining the necessary pressure to inflate the parison (hollow tube of plastic) and shape it into the desired product. This system typically consists of three main components: the air compressor, the accumulator, and the pressure regulator.

1. Air Compressor: The air compressor is the heart of the pressure system. It supplies compressed air to the machine at a high pressure, typically between 100-150 psi. This compressed air is stored in a tank and then fed into the accumulator.

2. Accumulator: The accumulator is a large tank that stores the compressed air from the air compressor. It acts as a buffer, ensuring a steady supply of air to the machine. The accumulator also helps to regulate the pressure and flow of air to the mold.

3. Pressure Regulator: The pressure regulator is responsible for controlling the amount of air that is released from the accumulator into the mold. It is connected to the accumulator and the mold and is set to maintain a specific pressure level during the blow molding process.

The pressure system works in the following steps:

1. The air compressor compresses air and stores it in the accumulator tank.

2. The accumulator tank releases the compressed air into the pressure regulator.

3. The pressure regulator controls the flow of air into the mold, maintaining a specific pressure level.

4. The mold is closed and the parison is placed inside.

5. The mold is then clamped shut and the parison is inflated with the compressed air, taking the shape of the mold.

6. Once the plastic has cooled and solidified, the mold is opened and the finished product is ejected.

7. The pressure system continues to supply compressed air to the mold until the desired product is formed.

The pressure system is crucial in ensuring the quality and consistency of the blow molded products. It must be carefully monitored and maintained to ensure proper pressure levels are maintained throughout the process.

11.What are the steps for cleaning and maintaining a 3000l blow molding machine?

We adhere to the principle of integrity and transparency, and establish long -term relationships with partners, and we attach great importance to this detail.

1. Shut off and unplug the machine: Before starting any cleaning or maintenance, make sure the machine is turned off and unplugged to avoid any accidents.

2. Remove excess material: Use a scraper or a brush to remove any excess material from the machine, including the mold, extruder, and die head.

3. Disassemble the machine: Depending on the type of blow molding machine, you may need to disassemble certain parts to access all the areas that need cleaning. Refer to the manufacturer's manual for specific instructions.

4. Clean the mold: Use a mild detergent and warm water to clean the mold. Make sure to remove any residue or buildup from the mold surface. You can also use a specialized mold cleaner for tougher stains.

5. Clean the extruder and die head: Use a brush or scraper to remove any residue or buildup from the extruder and die head. You can also use a specialized cleaner for these parts.

6. Check and clean the cooling system: The cooling system is essential for maintaining the temperature of the machine. Check for any clogs or buildup in the cooling channels and clean them with a brush or compressed air.

7. Lubricate moving parts: Use a lubricant recommended by the manufacturer to lubricate all the moving parts of the machine. This will help prevent wear and tear and ensure smooth operation.

8. Inspect and replace worn parts: Check all the parts of the machine for any signs of wear and tear. Replace any damaged or worn parts to ensure the machine's optimal performance.

9. Reassemble the machine: Once all the parts are cleaned and inspected, reassemble the machine following the manufacturer's instructions.

10. Test the machine: Before using the machine again, run a test cycle to ensure everything is working correctly.

11. Regular maintenance: To keep the machine in good working condition, it is essential to perform regular maintenance tasks such as cleaning, lubricating, and inspecting the machine. Refer to the manufacturer's manual for a recommended maintenance schedule.

Tags: hydraulic injection blow molding machine,plastic injection blow molding machine,practical extrusion blow molding,co-extrusion blow molding machine,single layer blow molding machine