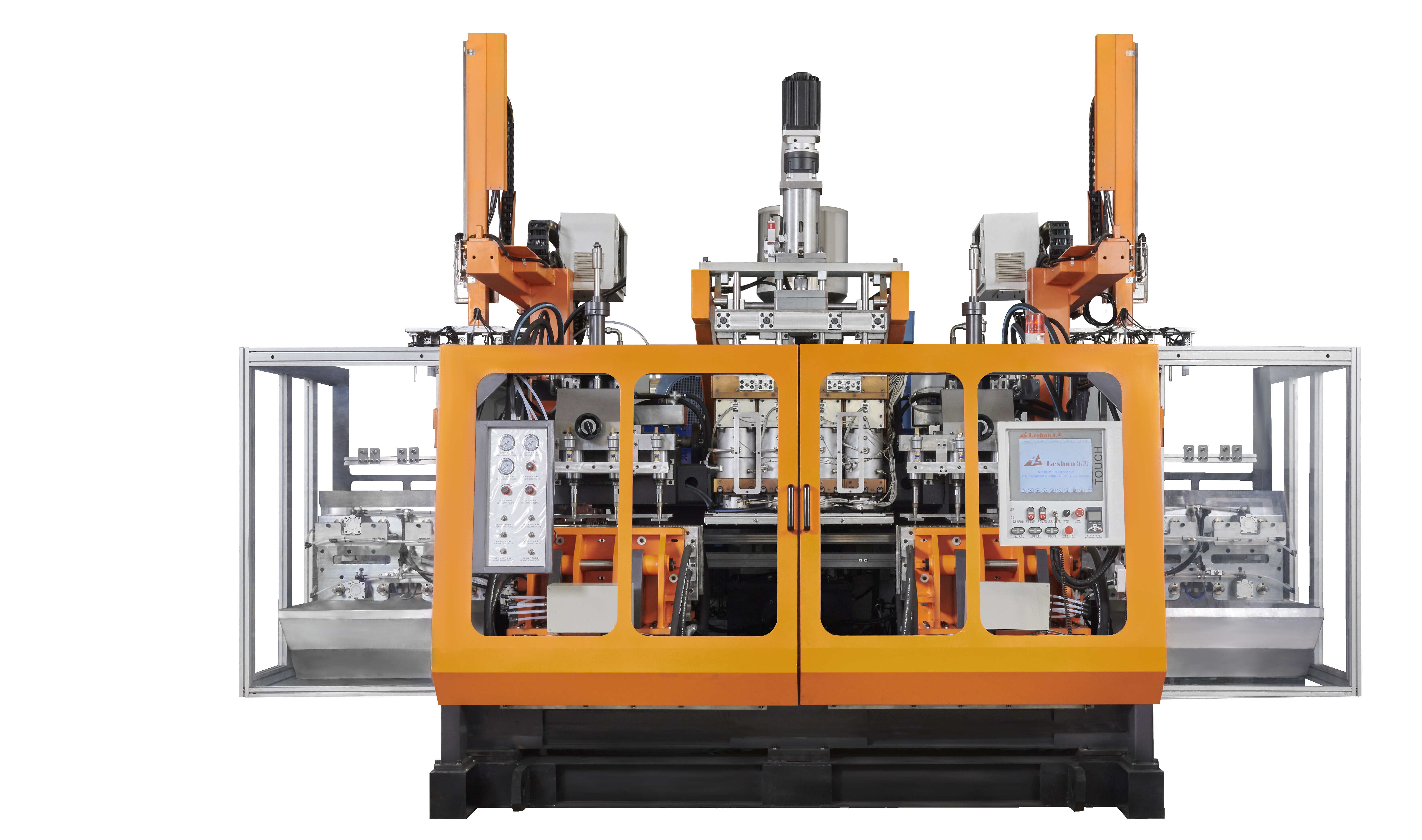

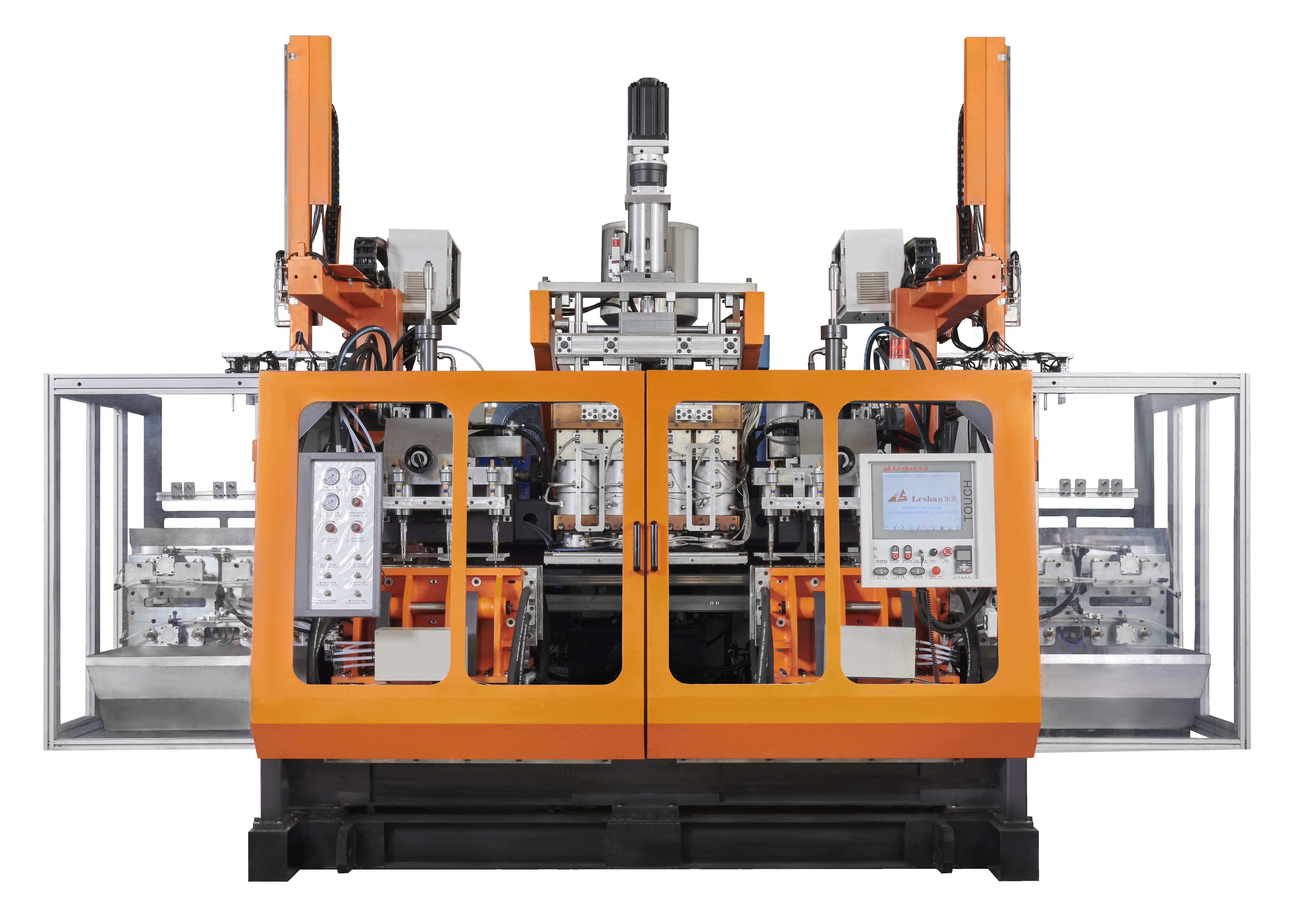

2l plastic bottle blow molding machine

2l plastic bottle blow molding machine

Leshan Machinery Company is a high-tech design and manufacturing company specializing in the production of blow molding machines and molds. Our products include: PET Machine,Milk bottle blow molding machine,Auxiliary machine,Irregular shape product blow molding machine,Chemical barrel blow molding machine,Blowing Mould & Injection Mould,athlon series hydraulic machine,multi-layer coextrusion blow molding machine,Extrusion Die Head,Engine oil bottle blow molding machine,Daily chemistry bottle blow molding machine, etc. We will continuously strive to meet the needs of our customers and seek development together with them. At present, our products are exported to more than 50 countries and regions such as Russia, Australia, Poland, Saudi Arabia, and Bangladesh.

Our company also brought in the Germanic technical 3D scanner which is exclusive used for mold-designing . The advanced Leshan Blow Molding Machine working with the superior Leshan Mould makes the production speed faster and the production quality the topest. Leshan Hydraulic Blow Molding Machine is adopted by many listed companies and China's top 500 enterprises, such as Bawang,Wahaha,Walch,Kunlun,Monarch,Cnice,Unilever,Sinopec, ect.

| Parameter | Information |

| Product Name | 2l plastic bottle blow molding machine |

| Brand Name | Leshan |

| Place of Origin | Foshan,China |

| PLC Brand | Siemens |

| Core Components | Engine,Motor,Gear,PLC,Bearing...etc |

| Warranty | 1year |

| Plastic Processed | PA,EVA,HDPE,ABS,PE,PVC,Polystyrene...etc |

| Application | Bottle |

| Port | ShunDe/GuangZhou/ShenZhen China |

| MOQ | 1 Set |

| Export Country | Russia, Australia, Poland,Eritrea,Ukraine,Faroe Islands,Zambia...etc |

| Export region | Oceania,Africa,Asia... |

| Certification | ISO 9001,CE...etc |

| Automatic | Yes |

| Screw L/D Ratio | 24 |

| Packaging Details | Standard exporting machine packing with plastic film |

| Color | Customized |

| Accumulator Capacity(L) | 100 L |

| Service | Online support... |

| Supply Ability | 500 Set/Sets per Month |

| Lead time (days) | 70 (To be negotiated) |

Please note: The above table data is for reference only. For specific information, please contact us.

2l plastic bottle blow molding machine is an indispensable and important equipment in modern plastic manufacturing industry, and its characteristics are constantly being improved and developed. Future blow molding machines will be more intelligent, energy-saving and environmentally friendly, and have more additional functions to meet changing market demands. At the same time, with the introduction of new degradable plastics, blow molding machines will also adapt to the processing of new materials, promoting the development of the plastic products industry in a more environmentally friendly and sustainable direction.

2l plastic bottle blow molding machine---FAQs Guide

2.How to solve the vibration problem of blow molding machine?

3.How does the pressure system of a 2l plastic bottle blow molding machine work?

4.How long does it usually take to troubleshoot 2l plastic bottle blow molding machine?

5.What types of blow molding machines are there?

6.How to maintain the stability of 2l plastic bottle blow molding machine?

7.How does the extrusion blow molding process differ from injection blow molding, and what types of products are typically produced using each method?

8.Where is your factory located? How can I visit there?

9.What is the cost composition of 2l plastic bottle blow molding machine?

10.What are the key components of a 2l plastic bottle blow molding machine?

1.How to optimize the efficiency of plastic blow molding machine?

It can improve the blowing process, improve the cooling water transportation of the mold, improve the machine action time, improve the shape of the cup to make the material tube become even, thus reducing the molding cycle time of the product.

2.How to solve the vibration problem of blow molding machine?

Adjust the pressure and flow parameters of carriage PQ valve to make the carriage action more smoothly.

3.How does the pressure system of a 2l plastic bottle blow molding machine work?

We have a first -class management team, and we pay attention to teamwork to achieve common goals.

The pressure system of a blow molding machine is responsible for creating and maintaining the necessary pressure to inflate the parison (hollow tube of plastic) and shape it into the desired product. This system typically consists of three main components: the air compressor, the accumulator, and the pressure regulator.

1. Air Compressor: The air compressor is the heart of the pressure system. It supplies compressed air to the machine at a high pressure, typically between 100-150 psi. This compressed air is stored in a tank and then fed into the accumulator.

2. Accumulator: The accumulator is a large tank that stores the compressed air from the air compressor. It acts as a buffer, ensuring a steady supply of air to the machine. The accumulator also helps to regulate the pressure and flow of air to the mold.

3. Pressure Regulator: The pressure regulator is responsible for controlling the amount of air that is released from the accumulator into the mold. It is connected to the accumulator and the mold and is set to maintain a specific pressure level during the blow molding process.

The pressure system works in the following steps:

1. The air compressor compresses air and stores it in the accumulator tank.

2. The accumulator tank releases the compressed air into the pressure regulator.

3. The pressure regulator controls the flow of air into the mold, maintaining a specific pressure level.

4. The mold is closed and the parison is placed inside.

5. The mold is then clamped shut and the parison is inflated with the compressed air, taking the shape of the mold.

6. Once the plastic has cooled and solidified, the mold is opened and the finished product is ejected.

7. The pressure system continues to supply compressed air to the mold until the desired product is formed.

The pressure system is crucial in ensuring the quality and consistency of the blow molded products. It must be carefully monitored and maintained to ensure proper pressure levels are maintained throughout the process.

4.How long does it usually take to troubleshoot 2l plastic bottle blow molding machine?

Our mission is to provide customers with the best solutions for 2l plastic bottle blow molding machine.

The time it takes to troubleshoot a blow molding machine can vary depending on the specific issue and the experience of the technician. In some cases, it may only take a few minutes to identify and fix the problem, while in more complex cases it may take several hours or even days to fully troubleshoot and resolve the issue. It is important to thoroughly diagnose and address any problems with the machine to ensure it is functioning properly and producing high-quality products.

5.What types of blow molding machines are there?

We should have a stable supply chain and logistics capabilities, and provide customers with high -quality, low -priced 2l plastic bottle blow molding machine products.

1. Extrusion blow molding machine: This type of machine uses a continuous extrusion process to produce hollow plastic products, such as bottles, containers, and tanks.

2. Injection blow molding machine: This machine combines the processes of injection molding and blow molding to produce small, complex, and precise plastic products, such as medical devices and electronic components.

3. Stretch blow molding machine: This machine uses a two-stage process to produce high-quality, lightweight bottles and containers from PET (polyethylene terephthalate) material.

4. Reheat stretch blow molding machine: This type of machine is similar to the stretch blow molding machine, but it uses preforms (partially formed bottles) instead of raw material to produce bottles and containers.

5. Rotational blow molding machine: This machine uses a rotating mold to produce large, hollow plastic products, such as tanks, drums, and toys.

6. Shuttle blow molding machine: This machine has a shuttle system that moves the mold back and forth, allowing for the production of larger and more complex products.

7. Injection stretch blow molding machine: This machine combines the processes of injection molding and stretch blow molding to produce high-quality, lightweight bottles and containers from PET material.

8. Accumulator blow molding machine: This machine uses an accumulator to store molten plastic, which is then used to produce large and complex products, such as automotive parts and industrial containers.

9. Continuous extrusion blow molding machine: This machine uses a continuous extrusion process to produce long, tubular plastic products, such as pipes and tubes.

10. Co-extrusion blow molding machine: This machine uses multiple extruders to produce products with multiple layers, allowing for the production of complex and multi-functional products.

6.How to maintain the stability of 2l plastic bottle blow molding machine?

We enjoy high authority and influence in the industry and continue to innovate products and service models.

1. Regular Maintenance: Regular maintenance is crucial for the stability of blow molding machines. This includes cleaning, lubricating, and inspecting the machine on a regular basis. Any worn or damaged parts should be replaced immediately to prevent further damage.

2. Proper Training: Ensure that all operators are properly trained on how to operate the blow molding machine. This will help prevent any accidents or damage to the machine due to operator error.

3. Use Quality Materials: The quality of the materials used in the blow molding process can affect the stability of the machine. Using high-quality materials will reduce the risk of machine breakdowns and improve the overall performance.

4. Monitor Machine Performance: Keep a close eye on the performance of the machine. This includes monitoring the temperature, pressure, and speed of the machine. Any abnormalities should be addressed immediately to prevent further damage.

5. Regular Inspections: Regularly inspect the machine for any signs of wear and tear. This will help identify any potential issues before they become major problems.

6. Follow Manufacturer's Guidelines: Follow the manufacturer's guidelines for operating and maintaining the machine. This will ensure that the machine is being used correctly and will help prolong its lifespan.

7. Keep the Machine Clean: A clean machine is less likely to experience breakdowns. Regularly clean the machine and remove any debris or dust that may have accumulated.

8. Proper Storage: When the machine is not in use, it should be stored in a clean and dry environment. This will help prevent any damage caused by moisture or dust.

9. Address Issues Immediately: If any issues arise with the machine, address them immediately. Ignoring problems can lead to more serious issues and can affect the stability of the machine.

10. Schedule Professional Servicing: It is important to schedule professional servicing of the machine on a regular basis. This will help identify any potential issues and ensure that the machine is running at its optimal performance.

7.How does the extrusion blow molding process differ from injection blow molding, and what types of products are typically produced using each method?

We have been working hard to improve service quality and meet customer needs.

Extrusion blow molding and injection blow molding are two different processes used to manufacture plastic products. While both methods involve melting plastic and shaping it into a desired form, there are some key differences between the two.

Extrusion blow molding is a process in which a molten tube of plastic, called a parison, is extruded through a die and then inflated to form a hollow product. The parison is then cooled and the mold opens to release the finished product. This process is commonly used to produce bottles, containers, and other hollow objects.

On the other hand, injection blow molding involves injecting molten plastic into a mold cavity, where it is then cooled and solidified. The mold then opens to release the finished product. This process is commonly used to produce small, complex, and precise products such as medical devices, pharmaceutical packaging, and small bottles.

One of the main differences between the two processes is the way the plastic is shaped. In extrusion blow molding, the plastic is shaped by the inflation of the parison, while in injection blow molding, the plastic is shaped by the mold cavity.

Another difference is the type of molds used. In extrusion blow molding, the molds are typically made of two halves that come together to form the desired shape. In injection blow molding, the molds are usually made of a single piece that is opened and closed to release the product.

The type of plastic used also differs between the two processes. Extrusion blow molding is typically used for high-density polyethylene (HDPE) and polyethylene terephthalate (PET) plastics, while injection blow molding is commonly used for polypropylene (PP) and polyethylene (PE) plastics.

In terms of product applications, extrusion blow molding is commonly used for larger, more simple products such as bottles and containers, while injection blow molding is used for smaller, more complex products such as medical devices and pharmaceutical packaging.

In summary, extrusion blow molding and injection blow molding are two different processes used to manufacture plastic products. While both methods involve melting plastic and shaping it into a desired form, they differ in the way the plastic is shaped, the type of molds used, and the types of products produced.

8.Where is your factory located? How can I visit there?

Our factory is located in Shunde, Foshan City, Guangdong Province, China. All our clients, from home or abroad, are warmly welcome to visit us!

9.What is the cost composition of 2l plastic bottle blow molding machine?

We focus on providing high 2l plastic bottle blow molding machine quality products and services.

The cost composition of blow molding machines can vary depending on the type and size of the machine, as well as the manufacturer and country of origin. However, the general cost composition can be broken down into the following components:

1. Machine base: This includes the main frame, base plate, and other structural components of the machine. It typically accounts for 20-30% of the total cost.

2. Extruder: The extruder is the heart of the blow molding machine and is responsible for melting and shaping the plastic material. It can account for 30-40% of the total cost.

3. Molds: Molds are used to shape the plastic material into the desired product. The cost of molds can vary greatly depending on the complexity and size of the product being produced. It can account for 20-30% of the total cost.

4. Control system: The control system includes the electrical and electronic components that control the operation of the machine. It can account for 10-15% of the total cost.

5. Hydraulic system: The hydraulic system is responsible for providing the necessary pressure and power to operate the machine. It can account for 5-10% of the total cost.

6. Other components: Other components such as motors, pumps, valves, and sensors can also contribute to the overall cost of the machine.

In addition to these components, the cost of blow molding machines may also include expenses such as labor, transportation, and installation. It is important to note that the cost composition may vary depending on the specific features and capabilities of the machine.

10.What are the key components of a 2l plastic bottle blow molding machine?

Our 2l plastic bottle blow molding machine products have competitive and differentiated advantages, and actively promote digital transformation and innovation.

1. Extruder: This is the main component of a blow molding machine, which melts and forms the plastic material into a parison (hollow tube).

2. Die Head: The die head is responsible for shaping the parison into the desired shape and size.

3. Clamping Unit: This unit holds the mold in place and provides the necessary pressure for the blowing process.

4. Blow Pin: The blow pin is used to inflate the parison and shape it against the mold.

5. Cooling System: After the parison is blown and formed into the desired shape, a cooling system is used to cool and solidify the plastic.

6. Ejection System: Once the plastic has cooled and solidified, the ejection system removes the finished product from the mold.

7. Control System: The control system is responsible for monitoring and controlling the various components of the machine, such as temperature, pressure, and speed.

8. Mold: The mold is a crucial component of a blow molding machine, as it determines the final shape and size of the product.

9. Hydraulic System: The hydraulic system provides the necessary power and pressure for the various movements and functions of the machine.

10. Electrical System: The electrical system supplies power to the machine and controls the various electrical components.

11. Safety Features: Blow molding machines are equipped with various safety features, such as emergency stop buttons, safety guards, and sensors, to ensure safe operation.

Tags: plastic box blow molding machine,auto hot fill blow molding machine,fully automatic blow mold machine,water pot blow molding machine